It’s a maintenance nightmare. Production halts, but the hose hasn’t burst. Instead, it looks “sick”—spongy, swollen, and internally delaminated like a clogged artery. This isn’t a pressure failure; it’s a chemical compatibility failure.

For decades, standard synthetic rubber hoses (like SAE 100R1 or 100R2) have been the backbone of the hydraulic industry. They are excellent for petroleum-based hydraulic fluids and lubricating oils. However, the industrial landscape is changing. Modern industries are using increasingly aggressive fluids—from harsh agricultural pesticides to volatile organic solvents and paints. In these chemical zones, standard rubber is outmatched.

As a leading manufacturer with over 15 years of experience, Kingdaflex has seen the shift toward specialized materials. The solution to the “swelling nightmare” lies in a different class of hose entirely: The Thermoplastic Hydraulic Hose (SAE 100R7 and SAE 100R8).

The Anatomy of Resistance: Nylon vs. Rubber

To understand why SAE 100R7 and SAE 100R8 are superior in chemical applications, we have to look at the molecular level.

Why Rubber Fails

Traditional hydraulic hoses are typically made from NBR (Nitrile Butadiene Rubber) or SBR blends. While these are cost-effective and flexible, rubber is inherently porous on a microscopic scale. When introduced to aggressive solvents or certain bio-based fluids, the chemical molecules permeate these pores.

This “absorption” causes the rubber polymer chains to relax and expand—a process known as swelling. A swollen hose loses its structural integrity. The inner tube softens and can be stripped away by the flow of fluid, sending chunks of rubber downstream to destroy expensive valves and pumps. Conversely, some chemicals leach the plasticizers out of the rubber, causing it to become rock-hard, brittle, and prone to cracking under the slightest movement.

The Thermoplastic Difference: The Nylon Shield

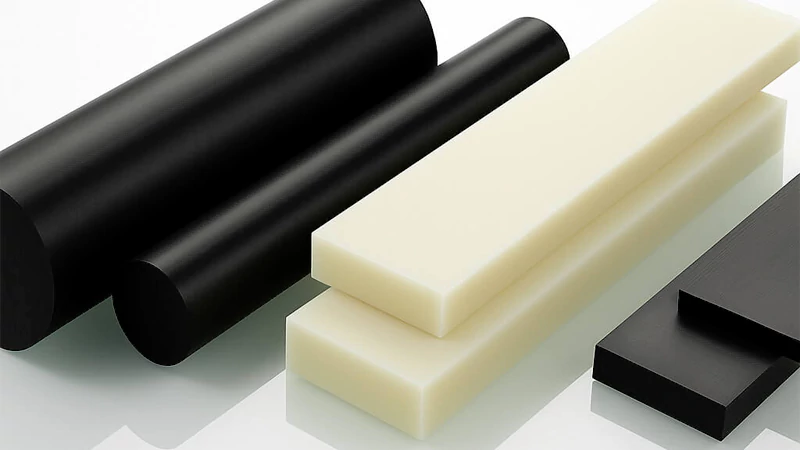

The SAE 100R7 and SAE 100R8 hoses are built differently. Instead of rubber, the inner tube is constructed from an oil-resistant synthetic thermoplastic core, typically Nylon (Polyamide).

Nylon is a semi-crystalline polymer. Its molecular structure is tightly packed and highly ordered, creating an almost impermeable barrier. When aggressive chemicals try to attack a Kingdaflex thermoplastic hose, they hit a wall.

- No Pores: The dense structure prevents fluid absorption.

- No Leaching: There are no plasticizers to be chemically extracted.

- No Reaction: Nylon is chemically inert to a vast range of substances that destroy rubber.

This fundamental difference in material science allows our R7 and R8 hoses to operate in environments where rubber hoses would fail in a matter of days.

Specific Chemical Enemies: What R7/R8 Can Handle

“Chemical resistance” is a broad term. Let’s look at the specific industrial battlegrounds where SAE 100R7 and R8 hoses are the preferred weapon of choice.

1. Paints, Solvents, and Thinners

One of the most distinct applications listed in our catalogue for both SAE 100R7 and SAE 100R8 is “spurting the oil paint”. This refers to airless paint sprayers and industrial coating lines.

Industrial paints, lacquers, and varnishes often contain aggressive solvents like acetone, MEK (Methyl Ethyl Ketone), or xylene.

- The Rubber Failure: Solvents dissolve the inner liner of rubber hoses. worse, the rubber can “leach” black carbon black particulates into the paint stream, ruining the color consistency and finish of the product.

- The R7/R8 Solution: The Nylon core of Kingdaflex thermoplastic hoses is unaffected by these solvents. It ensures that the fluid exiting the hose is exactly the same as the fluid entering it—pure and uncontaminated. This makes it the industry standard for paint spray applications.

2. Agricultural Chemicals (Pesticides & Fertilizers)

Agriculture is no longer just about water and diesel. Modern farming relies on complex chemical cocktails for crop protection and fertilization. These fluids can be highly acidic or alkaline.

- The Rubber Failure: Acids can eat through rubber, eventually reaching the steel wire reinforcement of standard hoses. Once the steel corrodes, the hose bursts.

- The R7/R8 Solution: Our catalogue explicitly lists “agriculture” as a key application for these hoses. The thermoplastic tube resists corrosion from fertilizers, while the abrasion-resistant polyurethane cover protects the hose from external exposure to these chemicals in the field. Furthermore, the reinforcement in our R7/R8 hoses is a synthetic fiber, not steel, meaning it is immune to rust even if the cover is breached.

3. Synthetic & Fire-Resistant Hydraulic Fluids

In industries like aviation, mining, or steel manufacturing, standard petroleum oils are replaced by fire-resistant fluids (like Phosphate Esters) to prevent fires.

- The Rubber Failure: Standard NBR rubber dissolves almost instantly in Phosphate Esters.

- The R7/R8 Solution: The chemical inertness of the Nylon core allows Kingdaflex thermoplastic hoses to handle a wider variety of synthetic hydraulic fluids without degradation.

Beyond Resistance: The “Cleanliness” Factor

Chemical resistance isn’t just about the hose surviving; it’s about the hose performing. In applications involving paints, glues, or precision hydraulics, “cleanliness” is a critical performance metric.

Smooth Bore Technology

The manufacturing process of a rubber hose involves a mandrel and a wrapping process that often leaves a slightly rough, textured surface on the inner tube. In contrast, the thermoplastic core of R7 and R8 hoses is extruded to create a mirror-smooth surface.

- Reduced Pressure Drop: The smooth surface creates less friction, allowing fluids to flow more efficiently.

- Easy Cleaning: When changing paint colors or fluid types, the smooth Nylon surface doesn’t trap residue. You can flush the hose quickly and effectively with a solvent, reducing changeover time and waste.

- No Contamination: As mentioned earlier, the risk of “leaching” (extractables) is virtually eliminated. This is vital for systems where fluid purity is paramount.

R7 vs. R8: Which One for Your Chemical Application?

You have decided that you need the chemical resistance of a thermoplastic hose. But which one do you choose: SAE 100R7 or SAE 100R8?

Both hoses share the same chemical-resistant DNA:

- Tube: Oil-resistant synthetic thermoplastic core (Nylon).

- Cover: Abrasion-resistant polyurethane.

- Temperature Range: -40°C to +100°C.

The difference lies in the reinforcement and pressure capability:

SAE 100R7: The Flexible Choice

- Reinforcement: This hose features one braid of high tensile synthetic fiber.

- Pressure: It is designed for medium-pressure applications. For example, a 3/8″ R7 hose has a working pressure of 155 Bar (2248 PSI).

- Best For: Agricultural sprayers, pilot lines, and medium-pressure lubrication lines where flexibility is key.

SAE 100R8: The High-Pressure Choice

- Reinforcement: This hose is beefed up with two braids of high tensile synthetic fiber.

- Pressure: It handles significantly higher pressures. A 3/8″ R8 hose is rated for 300 Bar (4350 PSI) —nearly double the capacity of the R7.

- Best For: High-pressure hydraulic tools, high-viscosity chemical injection, and heavy-duty construction machinery.

Conclusion

If your operation is plagued by swollen hoses, contaminated fluids, or frequent failures in chemical environments, switching to another brand of rubber hose will not solve the problem. You are fighting a chemical war with the wrong armor.

You need to change the material science.

SAE 100R7 and SAE 100R8 thermoplastic hoses offer the Nylon-based shield your equipment needs. They resist the solvents that dissolve rubber, withstand the environmental abuse of agriculture, and deliver the clean flow required for precision painting.

Stop accepting hose failure as a “cost of doing business.” Upgrade to Thermoplastic.

Ready to proof your system against chemical attack? Contact Kingdaflex today. Our team is ready to help you select the right R7 or R8 hose for your specific application.

- Email: [email protected]

- WhatsApp/WeChat: +86 186 6197 1632