Nitrile Butadiene Rubber (NBR) is a versatile synthetic rubber widely used in industries that demand excellent oil, fuel, and chemical resistance. Known for its durability and flexibility, NBR has become a preferred material in automotive, industrial, and hydraulic applications where performance under pressure is critical.

From fuel hoses to seals and gaskets, NBR’s unique properties make it an essential material in manufacturing. This guide explores what NBR is, its key characteristics, how it’s made, and why it continues to play a vital role in modern engineering and production environments.

What is NBR?

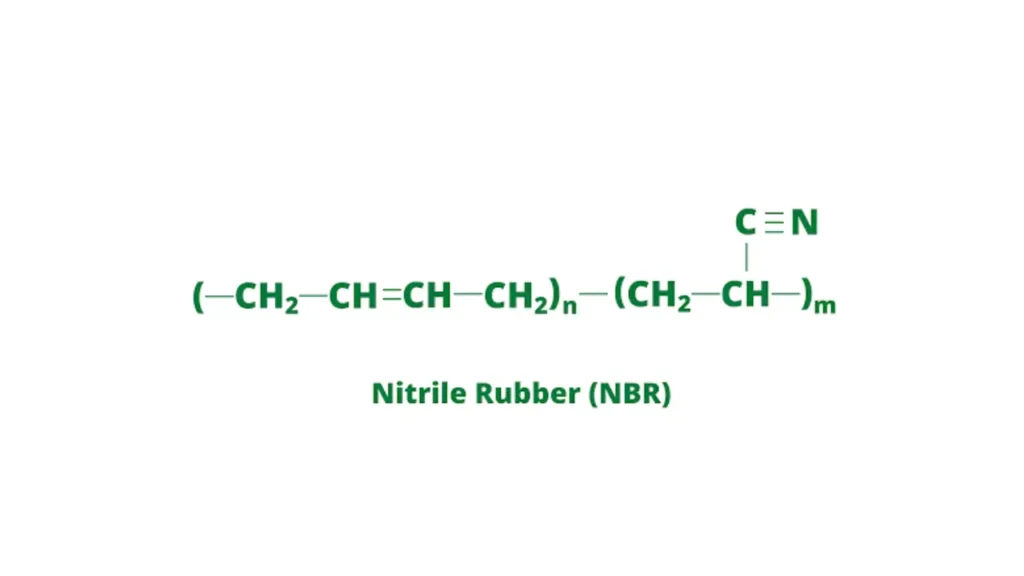

NBR, or Nitrile Butadiene Rubber, is a synthetic elastomer made from acrylonitrile and butadiene. It is widely known for its excellent resistance to oil, fuel, and chemicals, making it ideal for automotive, industrial, and hydraulic applications.

NBR combines flexibility, durability, and temperature tolerance, offering reliable performance in demanding environments.

NBR Hose Benefits

NBR hoses are valued for their durability, flexibility, and strong resistance to oils, fuels, and chemicals. These hoses are designed to perform reliably under pressure and temperature variations, making them ideal for automotive, industrial, and hydraulic applications that require strength and long-lasting performance.

- Excellent Oil and Fuel Resistance: NBR hoses resist swelling, cracking, and degradation caused by petroleum-based fluids. This ensures dependable performance in engines, fuel systems, and machinery, maintaining consistent flow and preventing leaks even under continuous exposure to oils and fuels.

- High Temperature Tolerance: Designed to withstand a wide range of temperatures, NBR hoses perform effectively in both hot and cold environments. Their stability under extreme conditions prevents hardening or softening, ensuring long service life and reducing the risk of failure during operation.

- Superior Flexibility: NBR hoses remain flexible without kinking or collapsing, even under pressure or tight bending conditions. This flexibility allows for easy installation, reliable movement in dynamic systems, and long-term resilience in applications with constant vibration or motion.

- Strong Abrasion Resistance: The tough outer layer of NBR hoses protects against wear, friction, and surface damage. This feature makes them ideal for industrial use, where hoses are exposed to rough surfaces or frequent handling, ensuring consistent performance and minimal maintenance.

- Versatile Applications: NBR hoses are suitable for a wide variety of uses, including automotive fuel lines, hydraulic systems, and oil transfer. Their versatility and durability make them a dependable solution for both light-duty and heavy-duty industrial environments around the world.

NBR Hose Applications

NBR hoses are widely used across multiple industries due to their excellent resistance to oils, fuels, and chemicals. Their strength, flexibility, and durability make them ideal for handling various fluids under high pressure and temperature, ensuring reliable performance in both industrial and automotive environments.

- Automotive Fuel Systems: NBR hoses are commonly used for fuel delivery, oil lines, and emission systems. Their resistance to gasoline, diesel, and lubricants ensures leak-free operation, maintaining vehicle efficiency and performance while withstanding constant vibration and exposure to high temperatures.

- Industrial Hydraulic Systems: In hydraulic machinery, NBR hoses handle oil transfer and fluid power transmission efficiently. They maintain flexibility under pressure, resist degradation from hydraulic fluids, and ensure stable system performance in construction, manufacturing, and agricultural equipment.

- Oil and Gas Applications: NBR hoses are ideal for transporting petroleum-based products and lubricants. Their robust construction and oil resistance make them suitable for refineries, offshore platforms, and service stations where durability and chemical stability are essential for safety and reliability.

- Chemical Processing Plants: Resistant to various chemicals and solvents, NBR hoses are used in transferring industrial fluids safely. They prevent contamination, reduce wear, and maintain strong sealing properties, making them suitable for chemical production and maintenance applications requiring consistent fluid handling.

- Marine and Aviation Use: NBR hoses perform well in marine and aviation fuel systems. Their resistance to oil, saltwater, and weathering ensures stable performance and safety, supporting fuel delivery and lubrication systems in harsh and corrosive operating environments.

How to Choose Suitable NBR Hoses?

Selecting the right NBR hose ensures safe, efficient, and long-lasting performance in your system. The proper choice depends on factors like operating pressure, temperature, and the type of fluid being transferred. Understanding these elements helps you select the best hose for your specific application.

- Consider Working Pressure: Choose an NBR hose rated above your system’s maximum operating pressure. This safety margin prevents bursting or leaks, ensuring reliable performance. Regularly check pressure ratings to match your machinery requirements and maintain optimal durability during heavy-duty or continuous use.

- Evaluate Temperature Range: NBR hoses must withstand both high and low temperatures without losing flexibility. Select hoses with temperature resistance suitable for your working environment to avoid hardening, softening, or cracking, ensuring continuous and safe operation in changing thermal conditions.

- Identify Fluid Compatibility: Verify that the NBR hose material is compatible with the fluids you plan to transfer, such as oil, fuel, or hydraulic fluids. Compatibility ensures chemical stability, prevents degradation, and maintains hose performance over time, avoiding premature wear or contamination.

- Check Size and Fittings: Select the correct inner diameter, length, and fitting type for your system. Proper sizing minimizes flow resistance, prevents leaks, and ensures a secure connection between components, improving efficiency and preventing mechanical stress during operation.

- Assess Environmental Conditions: Consider external factors such as abrasion, UV exposure, and contact with chemicals. Choosing NBR hoses with reinforced outer layers or protective coatings ensures resistance against environmental wear, extending hose lifespan and maintaining safety in tough industrial conditions.

Conclusion

Nitrile Butadiene Rubber stands out as one of the most reliable materials for fluid sealing and fuel-resistant applications. Its excellent balance of toughness, flexibility, and chemical resistance ensures consistent performance even under extreme operating conditions, making it indispensable across multiple industries worldwide.

By understanding NBR’s composition and advantages, manufacturers and engineers can choose the right grade for their specific needs. Whether used in automotive systems, oil transfer, or hydraulic machinery, NBR provides a cost-effective and dependable solution that enhances overall system efficiency and durability.

At Kingdaflex, we specialize in providing high-quality NBR rubber hoses at wholesale prices. Our products are designed for long-lasting performance, exceptional oil resistance, and flexibility under pressure. Partner with Kingdaflex today to get durable, customized NBR rubber hoses tailored to your industrial or commercial applications.