SBR, or Styrene-Butadiene Rubber, is a versatile synthetic rubber widely used in industrial and consumer products. Known for its durability, abrasion resistance, and heat tolerance, SBR is an essential material in manufacturing tires, hoses, belts, gaskets, and flooring, offering a cost-effective alternative to natural rubber without compromising performance.

This guide explores the key properties, benefits, and applications of SBR, helping you understand why it’s a preferred choice for various industries. Whether you are sourcing materials for automotive, construction, or industrial projects, knowing the characteristics of SBR ensures better product selection and improved performance for your application.

What is SBR?

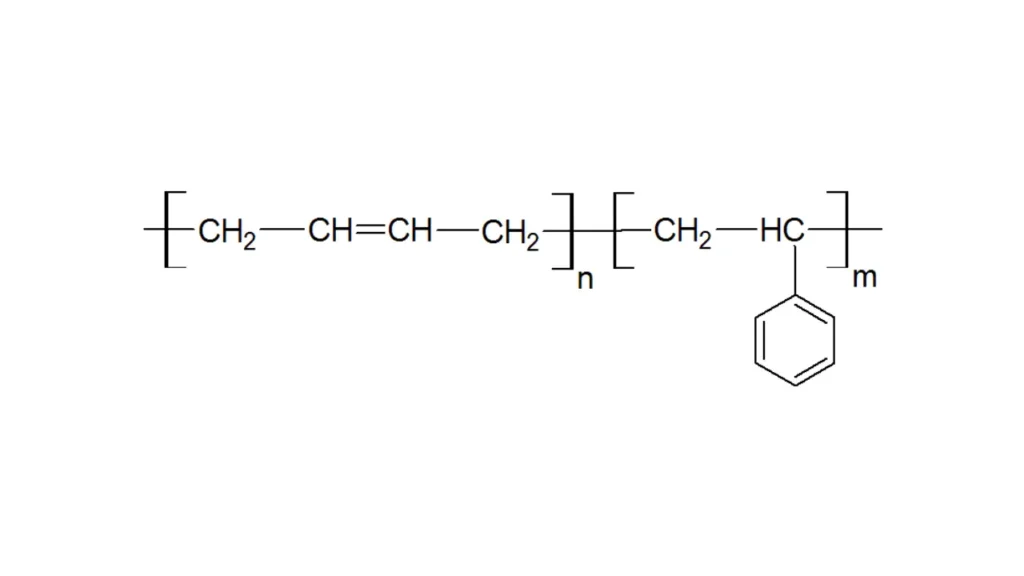

SBR, or Styrene-Butadiene Rubber, is a synthetic rubber made by polymerizing styrene and butadiene. It is valued for its durability, abrasion resistance, and heat tolerance, making it ideal for industrial and consumer products such as tires, hoses, belts, gaskets, and flooring. SBR provides a cost-effective alternative to natural rubber without compromising performance.

SBR Hose Benefits

SBR hoses are widely used in industrial and commercial applications due to their durability, flexibility, and resistance to wear. These hoses provide reliable performance in demanding environments, ensuring long service life and efficiency. Understanding their benefits helps you choose the right hose for your specific needs.

- Durable and Wear-Resistant: SBR hoses are built to withstand abrasion, mechanical stress, and repeated use. Their tough material ensures long-lasting performance even in harsh industrial conditions, reducing maintenance costs and downtime while providing reliable service across various applications.

- Heat and Weather Resistant: These hoses maintain flexibility and strength under high temperatures and exposure to sunlight, ozone, or weather changes. This resistance ensures safe, long-term operation in outdoor or industrial environments without cracking, hardening, or losing efficiency over time.

- Flexible and Easy to Handle: SBR hoses offer excellent flexibility, making them easy to bend, install, and maneuver in tight spaces. Their lightweight design reduces operator fatigue and allows smooth fluid flow, enhancing overall efficiency in pneumatic, hydraulic, and water transfer applications.

- Cost-Effective Solution: Compared to other rubber hoses, SBR hoses provide excellent performance at a competitive price. Their durability, low maintenance, and long service life make them an economical choice for industries seeking quality and affordability without compromising reliability.

SBR Hose Applications

SBR (Styrene-Butadiene Rubber) hoses are versatile and durable, widely used in industries that require flexibility, abrasion resistance, and chemical stability. Their adaptability makes them ideal for handling various fluids, air, and materials under different environmental conditions, ensuring reliability and efficiency in daily operations.

- Air and Water Transfer – SBR hoses are perfect for transporting air and water in industrial and agricultural settings. Their flexibility allows easy maneuvering, while the durable rubber withstands pressure and temperature changes, ensuring long-term usage without cracking or leaking, providing consistent and safe fluid flow.

- Chemical Handling – These hoses can manage mild chemicals safely. Their synthetic rubber composition resists degradation and maintains hose integrity under exposure to oils, solvents, and other non-corrosive chemicals, making them suitable for laboratory, industrial, and manufacturing applications where chemical transfer reliability is crucial.

- Material Conveying – SBR hoses are widely used to convey sand, grains, powders, and other granular materials. Their abrasion resistance prevents wear during heavy-duty operations, ensuring smooth material flow and minimizing downtime in factories, construction sites, or agricultural environments.

- Automotive and Machinery Use – In vehicles and industrial machinery, SBR hoses transport coolant, air, or other fluids efficiently. Their heat resistance and durability under vibration make them a reliable choice for engines, pumps, and compressors, reducing maintenance needs and enhancing operational safety.

- Food and Beverage Applications – Food-grade SBR hoses can safely handle liquids and semi-solids in processing plants. They resist microbial growth, abrasion, and temperature fluctuations, ensuring sanitary transfer and minimal contamination risk, suitable for dairy, beverage, and food production environments.

SBR vs NBR Hose

SBR and NBR hoses are widely used in industrial, automotive, and fluid-handling applications. While both are synthetic rubber types, their material properties, chemical resistance, and performance under different conditions vary. Understanding their differences helps you choose the right hose for specific applications.

1. Material Composition

SBR hoses are made from styrene-butadiene rubber, offering excellent abrasion resistance and elasticity. They are ideal for general-purpose applications, such as air, water, and granular material transfer, where chemical exposure is minimal. Their versatility makes them a cost-effective choice for many industries.

NBR hoses are made from nitrile butadiene rubber, which excels in oil and fuel resistance. Their synthetic structure allows them to withstand petroleum-based fluids, hydraulic oils, and greases without degrading, making them suitable for automotive, hydraulic, and fuel-handling applications.

2. Chemical Resistance

SBR hoses have limited resistance to oils, fuels, and strong chemicals. They perform well with water, mild acids, and air but are not recommended for prolonged exposure to petroleum or aggressive chemicals. Proper selection ensures durability and prevents premature wear.

NBR hoses offer superior resistance to oils, fuels, and hydrocarbons. This makes them the preferred choice in applications requiring chemical stability under continuous exposure. They also resist swelling and cracking caused by contact with oils, improving hose lifespan in demanding conditions.

3. Temperature Tolerance

SBR hoses typically operate in a moderate temperature range (-40°C to 80°C). While they handle most industrial and agricultural conditions, they may degrade faster if exposed to extreme heat or cold, limiting their use in high-temperature systems.

NBR hoses withstand a broader temperature range (-40°C to 100°C). Their thermal stability ensures reliable performance in engines, hydraulic systems, and hot oil lines, maintaining flexibility and integrity under varying operating temperatures without compromising safety.

4. Abrasion and Wear Resistance

SBR hoses are highly resistant to abrasion, making them suitable for handling sand, gravel, or other particulate materials. Their tough outer layer prolongs service life in rugged environments, reducing replacement frequency and maintenance costs.

NBR hoses provide moderate abrasion resistance but excel in chemical and oil resistance. They are best for internal fluid transfer, where mechanical wear is minimal, and chemical exposure is critical. Using them in abrasive applications may reduce hose lifespan.

5. Cost and Availability

SBR hoses are generally more affordable and widely available. They are suitable for general-purpose industrial, agricultural, and water transfer applications where extreme chemical or fuel resistance is not required.

NBR hoses are slightly more expensive due to their specialized chemical and oil-resistant properties. They are essential in automotive, fuel, and hydraulic systems where durability under chemical exposure outweighs cost considerations.

Comparison Table

| Feature | SBR Hose | NBR Hose |

|---|---|---|

| Material | Styrene-Butadiene Rubber | Nitrile Butadiene Rubber |

| Chemical Resistance | Limited, water/mild chemicals | Excellent, oils, fuels, hydrocarbons |

| Temperature Range | -40°C to 80°C | -40°C to 100°C |

| Abrasion Resistance | High | Moderate |

| Applications | General-purpose, air, water, granular materials | Oil, fuel, hydraulic, automotive systems |

| Cost | Lower | Higher |

How to Choose Suitable SBR Hoses?

Choosing the right SBR hose is essential for efficiency, durability, and safety in industrial, agricultural, or automotive applications. Selecting the correct type involves considering pressure, temperature, chemical exposure, and material compatibility. Understanding these factors ensures optimal hose performance and longevity while minimizing maintenance and replacement costs.

- Determine the Application Type – Identify whether the hose will carry water, air, granular materials, or mild chemicals. Knowing the specific use helps in selecting the correct SBR hose type, wall thickness, and reinforcement to handle operational demands without premature wear or leakage.

- Check Pressure and Temperature Ratings – Assess the working pressure and temperature conditions the hose will face. SBR hoses must withstand these parameters to maintain performance and prevent failure. Always choose hoses with ratings above the expected maximum to ensure safety and reliability.

- Consider Chemical Compatibility – Evaluate the fluids or substances the hose will contact. SBR hoses perform well with water and mild chemicals but may degrade with oils or strong solvents. Selecting a hose compatible with your materials prevents damage and extends service life.

- Examine Flexibility and Durability – Ensure the hose is flexible enough for installation and operation while being durable against abrasion, bending, and environmental factors. High-quality SBR hoses resist cracking, wear, and UV damage, maintaining efficiency and reducing maintenance costs over time.

- Evaluate Size and Length Requirements – Proper diameter and length selection is crucial for optimal flow and minimal pressure loss. Oversized or undersized hoses can reduce efficiency or cause strain. Accurate measurements help maintain system performance and prevent unnecessary operational issues.

Conclusion

Understanding SBR and its properties is crucial for selecting the right material for your industrial or consumer needs. From superior abrasion resistance to flexibility in various conditions, SBR proves its value across multiple applications. Choosing quality SBR products ensures durability, efficiency, and reliability in every project.

SBR’s versatility makes it an ideal material for tires, hoses, belts, and other industrial products. Its combination of performance and cost-effectiveness allows manufacturers and businesses to meet demanding requirements while staying within budget. With the right SBR material, your products can achieve enhanced durability and long-term operational success.

For those looking to source high-quality SBR hoses, Kingdaflex provides reliable wholesale solutions. Our SBR hoses are designed to deliver consistent performance, durability, and safety across diverse applications. Partnering with Kingdaflex ensures you receive premium SBR products that meet industrial standards and support the success of your projects from start to finish