For Maintenance Managers in the food, pharma, and chemical industries, the daily washdown cycle is often the biggest threat to equipment reliability.

Standard rubber hoses simply cannot survive the rigorous demands of Clean-In-Place (CIP) and Steam-In-Place (SIP) protocols.

When exposed to high-pressure steam (+150°C) and aggressive caustics, organic rubber hoses quickly harden, crack, or swell. This “chemical embrittlement” leads to dangerous leaks, contamination risks, and expensive unscheduled downtime.

Unlike rubber, our Stainless Steel Braided PTFE (Teflon) hose is chemically inert and thermally stable. It is engineered to withstand extreme temperature fluctuations and harsh cleaning agents without degrading. In this guide, we explain why upgrading to Kingdaflex SAE 100R14 PTFE hose is the most cost-effective decision for your facility’s hygiene and efficiency.

The Chemistry of Cleaning: What SAE 100R14 PTFE Hoses Must Endure

To understand why standard hoses fail, we must look at the brutal environment created during a washdown cycle. Your hoses are not just transporting fluids; they are surviving a battlefield of physics and chemistry.

There are two primary forces at work that destroy rubber and thermoplastic hoses: Thermal Shock and Chemical Attack.

The Physical Stress: Thermal Shock

During a Steam-In-Place (SIP) cycle, the internal temperature of the hose can skyrocket from ambient room temperature (20°C) to over 130°C (266°F) in a matter of seconds.

Rapid Expansion: This sudden heat causes the inner tube material to expand rapidly.

Contraction: When the cycle ends and cold water is flushed through, the material contracts just as quickly.

For rubber hoses, this constant expansion and contraction breaks down the molecular bonds (cross-linking) over time. The result is hardening and micro-cracking. Once cracks appear, the hose loses its flexibility and becomes a ticking time bomb for a blowout.

The Molecular Stress: Chemical Attack

Heat is only half the battle. Clean-In-Place (CIP) protocols utilize aggressive chemicals to sanitize equipment. Standard rubber compounds (like NBR or EPDM) often have specific weaknesses against the “Big Three” industrial cleaners:

Caustics (e.g., Sodium Hydroxide/Caustic Soda): Used to remove organic soils (fats, oils, proteins). High concentrations can cause rubber to swell and soften.

Acids (e.g., Nitric or Phosphoric Acid): Used to remove mineral scale and rust. These can cause surface embrittlement in non-resistant materials.

Sanitizers (e.g., Peracetic Acid or Hypochlorite): These powerful oxidizers are designed to kill bacteria, but they also attack the polymer chains of organic rubber hoses, leading to “gummy” degradation or flaking.

If your hose material absorbs these chemicals (a process called leaching), it not only destroys the hose but risks contaminating your next batch of product with rubber particles or chemical residue.

Why SAE 100R14 PTFE is the “King of Cleanability”

While rubber fights a losing battle against chemistry and physics, PTFE (Polytetrafluoroethylene) simply ignores them.

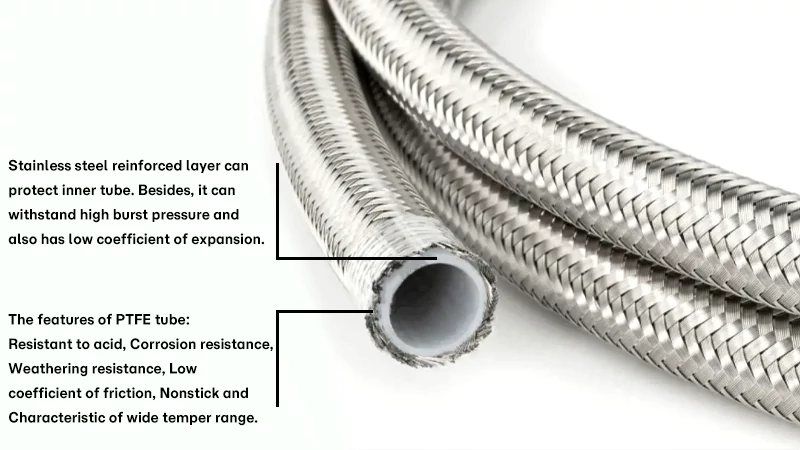

The Kingdaflex SAE 100R14 hose is built around a smooth-bore core of extruded PTFE. This material possesses unique properties that make it the ultimate choice for washdown environments:

1. Total Chemical Immunity (pH 0-14)

Unlike rubber, which relies on specific additives to resist certain chemicals, PTFE is naturally inert. It creates a virtually impenetrable barrier against aggressive fluids.

- Caustics? No effect.

- Acids? No effect.

- Solvents? No effect. Whether you are flushing with concentrated Sodium Hydroxide or aggressive nitric acid, the Kingdaflex PTFE liner remains chemically unchanged. It will not swell, dissolve, or erode.

2. Mastering the Heat (-60°C to +204°C)

Remember the thermal shock mentioned earlier? Kingdaflex SAE 100R14 hoses are rated for continuous operation from -60°C to +204°C (-75°F to +400°F). This exceeds the requirements of standard industrial steam cleaning (typically 121°C – 135°C). You can switch instantly from hot steam to cold water rinsing without fear of the hose cracking or becoming brittle.

3. The “Non-Stick” Advantage

PTFE has one of the lowest coefficients of friction of any solid material. Just like a non-stick frying pan, substances struggle to adhere to the smooth inner wall of our hose.

- Faster Cleaning: Residue and bacteria have nowhere to hide and slide off easily during flushing.

- Efficiency: This “self-cleaning” property means you can use less water and less solvent to achieve the same level of sanitation, reducing your overall waste disposal costs.

4. Zero Absorption (No Flavor Transfer)

Rubber is porous; it acts like a sponge, absorbing odors and flavors over time. PTFE is non-porous. It ensures zero absorption and zero leaching. You can use the same hose to transfer a strong-smelling cleaning agent, flush it, and immediately use it for a sensitive product without any risk of cross-contamination or “off-tastes.”

The Structural Advantages of SAE 100R14 Hose: The Stainless Steel Braid

If the PTFE liner is the “shield” against chemical attack, the stainless steel braid is the “armor” against physical abuse.

A common misconception is that PTFE tubes are fragile. While a bare PTFE tube can kink or burst under pressure, Kingdaflex SAE 100R14 is reinforced with a high-tensile AISI 304 or 316 Stainless Steel wire braid. This structural design solves three critical problems in industrial cleaning applications:

1. High-Pressure Safety

Steam cleaning often involves pressure spikes. The stainless steel braid acts as a containment cage, preventing the PTFE liner from expanding or “ballooning” under heat and pressure.

- Pressure Rating: Even in small diameters, our R14 hose can handle working pressures exceeding 1,500 PSI (100 Bar), providing a massive safety margin for standard washdown guns (which usually operate below 100 PSI).

2. “Drag” Resistance (Abrasion Protection)

In a real-world factory environment, washdown hoses are rarely treated gently. They are dragged across rough concrete floors, pulled around sharp machinery corners, and stepped on.

- Rubber Hoses: The outer cover tears and wears down, exposing the reinforcement layers to moisture and rust.

- Kingdaflex S.S. Braid: The stainless steel mesh provides exceptional abrasion resistance. It acts as a sliding surface, protecting the core tube from cuts, gouges, and external wear.

3. Kink Resistance

While smooth-bore PTFE is naturally stiffer than rubber, the tight stainless steel braiding adds structural integrity. It helps distribute bending forces, reducing the risk of the hose collapsing or kinking when maneuvered around tight spaces during equipment cleaning.

Kingdaflex Difference: We utilize high-density braiding technology. This ensures maximum coverage, meaning there are no “gaps” in the wire mesh where the inner tube could be exposed to damage.

SAE 100R14 vs. Traditional Steam Hoses: The ROI Calculation

When selecting a hose for washdown stations, the initial purchase price is often misleading. The true cost includes replacement frequency, downtime, and operator fatigue.

Here is how Kingdaflex SAE 100R14 stacks up against the traditional alternatives found in most factories:

VS. Rubber Steam Hose (EPDM)

- The Problem: EPDM rubber is the industry standard, but it has a fatal flaw known as “Popcorning.” Over time, steam penetrates the inner rubber wall, condenses into water, and then expands explosively when the hose is reheated. This creates bubbles and blisters inside the tube, leading to blockages and rupture.

- The Weight Factor: Rubber steam hoses are heavy and bulky. Dragging a heavy rubber hose around a facility all day leads to operator fatigue.

- The Verdict: Rubber is cheaper upfront but requires frequent replacement (often every 3-6 months in heavy use). SAE 100R14 offers a significantly longer service life, often lasting years.

VS. Corrugated Metal Hose

- The Problem: While stainless steel corrugated hoses handle extreme heat well, they are notoriously difficult to clean. The “valleys” of the corrugations trap food particles, bacteria, and cleaning agents, making 100% sanitation nearly impossible.

- Flexibility: Metal hoses are stiff and prone to fatigue cracking if bent repeatedly at the same point—exactly what happens in manual washdown applications.

- The Verdict: Metal hoses are great for fixed piping, but terrible for handheld washdown guns. SAE 100R14’s smooth bore ensures zero entrapment and far superior ergonomics.

VS. Silicone Hose

- The Problem: Silicone is flexible and hygienic, but it lacks physical toughness. It has poor tear resistance and cannot handle the high pressures associated with industrial steam lines. It is also generally not compatible with strong acids or solvents used in CIP cycles.

- The Verdict: Silicone is for low-pressure fluid transfer, not for heavy-duty industrial cleaning.

Industry Specific Applications: Where SAE 100R14 Shines

Because of its unique combination of hygiene and durability, Kingdaflex SAE 100R14 is the “Universal Hose” for industries where cleanliness is non-negotiable.

Here is how different sectors utilize this technology to maintain sterility and efficiency:

1. Food & Beverage Processing

In food plants, cross-contamination is the enemy.

- The Application: Transferring edible oils, flavorings, and syrups, followed by high-temperature steam flushing.

- Why R14? The PTFE core is chemically inert and typically meets FDA requirements for food contact. Its non-stick surface ensures that sticky substances (like chocolate or caramel) are easily purged during the CIP cycle, preventing bacterial growth in the liner.

- Key Use Case: High-pressure washdown stations for cleaning conveyor belts and mixing tanks.

2. Pharmaceutical & Cosmetics

Manufacturers of medicines and perfumes use highly volatile solvents and alcohol-based compounds.

- The Application: Fluid transfer and equipment sterilization (SIP).

- Why R14? Purity is paramount. Rubber hoses can leach plasticizers into the product, altering the chemical composition of a drug or the scent of a perfume. Kingdaflex PTFE hoses ensure 100% product integrity with zero leaching.

3. Industrial Painting & Adhesives

This is one of the toughest environments for hoses.

- The Application: Flushing paint lines with aggressive solvents (like MEK, Acetone, or Thinners) to change colors.

- Why R14? Most rubber hoses will swell and dissolve when exposed to paint thinners. SAE 100R14 withstands continuous exposure to these harsh solvents without degrading, ensuring a clean color change every time.

4. Commercial Laundry & Chemical Dosing

- The Application: Transferring industrial-strength bleach, detergents, and hot water.

- Why R14? The stainless steel braid protects the hose from external abrasion in busy laundry facilities, while the PTFE core resists the corrosive effects of concentrated chlorine and peroxides.

How to Maximize SAE 100R14 Teflon Hose Life

While Kingdaflex SAE 100R14 is engineered for durability, it is not indestructible. PTFE is a thermoplastic, meaning its physical properties change slightly under extreme heat.

To get the best Return on Investment (ROI) from your new hoses, follow these expert maintenance guidelines:

1. The “Hot Bend” Rule (Crucial!)

This is the #1 mistake operators make. When PTFE is heated to steam temperatures (+150°C), it becomes softer and more pliable.

- The Rule: Do not bend the hose sharply immediately after a steam cycle while it is still hot.

- Why: If you force a tight bend while the PTFE is in this “plastic” state and then let it cool, it can “set” in that shape or, worse, kink. Allow the hose to cool slightly or keep it straight during the cool-down phase.

2. Inspect the “Armor”

The stainless steel braid is your first line of defense. Make it a habit to inspect the outer cover regularly.

- Look for “Fishhooks”: These are broken wire strands that stick out from the braid. Not only can these injure the operator’s hands, but they also indicate that the hose has been dragged over rough surfaces excessively. If the braid is significantly frayed, the pressure containment is compromised, and the hose should be replaced.

3. Proper Draining

Although the PTFE liner does not hold bacteria, the metal fittings (crimped ends) can trap moisture.

- Best Practice: After the final washdown, hang the hose vertically to allow gravity to drain any residual water or chemicals. This prevents stagnation in the ferrules and ensures the hose is dry and ready for the next shift.

4. Avoid “Torque” Stress

SAE 100R14 handles pressure well, but it hates being twisted.

- Installation Tip: When tightening the fittings to the washdown gun or the supply line, use two wrenches. One to hold the hose end stationary, and one to turn the nut. This prevents the hose from twisting during installation, which is a leading cause of premature failure.

Conclusion

In the demanding world of industrial sanitation, your choice of hose makes the difference between a smooth operation and a safety hazard.

Standard rubber hoses are a consumable item; they are designed to fail eventually. Kingdaflex SAE 100R14 PTFE Hose is an asset; it is designed to endure.

We don’t just sell hose; we provide engineered solutions.

Rigorous Testing: Every batch of our SAE 100R14 hose undergoes strict impulse and proof pressure testing to ensure it meets or exceeds SAE J517 standards. We don’t guess; we verify.

Custom Assemblies: Whether you need bulk rolls for your workshop or ready-to-use assemblies with crimped NPT, JIC, or Tri-Clamp fittings for your washdown guns, we can customize to your exact specifications.

Speed & Availability: We understand that downtime costs money. We maintain a large inventory of popular sizes (-4 to -16) to ensure fast shipping when you need it most.

Contact Our Team: Get a custom quote or technical advice today.

View Product Specs: Explore the full technical details of our SAE 100R14 series.