You should know what makes AN vs JIC fittings different. The biggest differences are in standards, materials, and how precise they are.

AN fittings use superior materials like aluminum or stainless steel and adhere to very strict regulations for aerospace applications.

In contrast, JIC fittings are more cost-effective and work well for everyday tasks. It is crucial to select the right fittings for safety, as mixing them can lead to leaks or other issues.

| Feature | AN Fittings | JIC Fittings |

|---|---|---|

| Material Quality | High-grade (aluminum, stainless steel) | More cost-effective materials |

| Precision | Tight tolerances | Less strict tolerances |

| Cost | Higher | Lower |

| Safety | Critical in high-stakes environments | Suitable for general use |

Choosing the right fittings ensures your system’s safety and can also save you money.

What are AN Fittings?

AN fittings—short for Army-Navy—are high-performance fluid connectors originally developed for military and aerospace applications. They feature a 37-degree flare design, which provides a secure, leak-free seal in high-pressure environments.

Key Features of AN Fittings:

- Thread Type: Uses UNF (Unified National Fine) threads

- Flare Angle: 37-degree flare for sealing

- Materials: Typically made from aluminum or stainless steel

- Sizes: Identified by a dash number (e.g., -6 AN = 6/16” or 3/8”)

AN fittings are widely used in performance automotive, racing, and aviation due to their reliability and easy installation.

What Are JIC Fittings?

JIC (Joint Industry Council) fittings are standardized hydraulic fittings that use a 37-degree flare seating surface to create a metal-to-metal seal. Made to SAE J514 standards, they are widely used in high-pressure fluid systems, especially in industries like agriculture, construction, and automotive.

Key Features of JIC Fittings:

- 37° Flare Design: Ensures a tight, leak-free seal.

- Thread Type: Straight threads (UNF/UN) with a mechanical seal.

- Material Options: Usually available in carbon steel, stainless steel, or brass.

- Reusability: Can be disconnected and reconnected multiple times without compromising performance.

JIC fittings are valued for their durability, versatility, and ease of use, making them a go-to choice for many hydraulic applications.

AN vs JIC Fittings: Core Differences

Thread Design

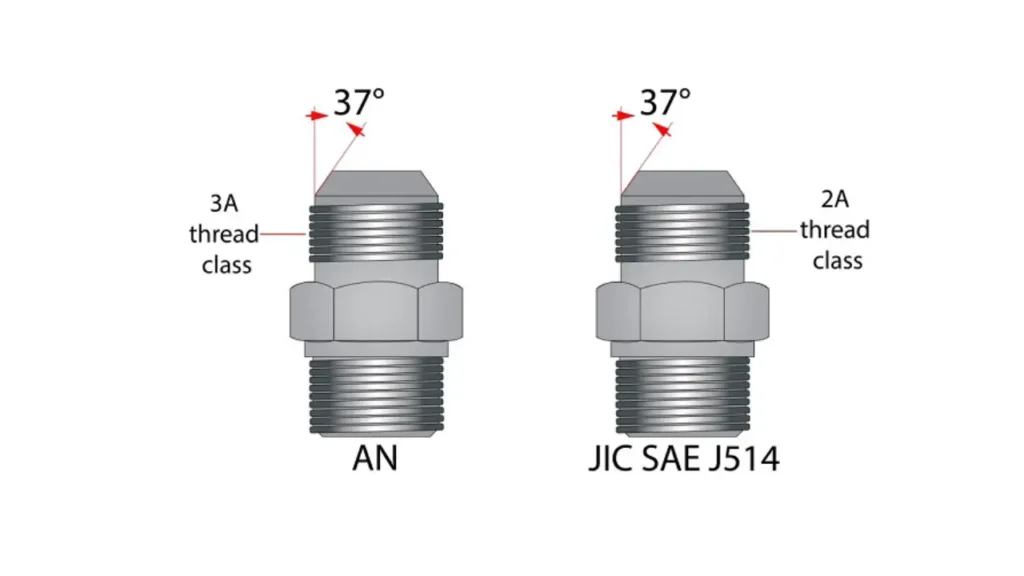

When you look at AN and JIC fittings, you can see they are not the same. Both use threads to make a tight seal. But the rules and how exact they are is what makes them different. AN fittings follow military rules called MIL-F-5509. This means they are more accurate and dependable. JIC fittings follow SAE J514 and ISO-8434-2 rules. These are good for normal jobs in factories.

Here is a table that shows the technical details:

| Fitting Type | Thread Class | Design Features | Applications |

|---|---|---|---|

| AN fittings | 3A/3B UNJ/UNJF | Enhanced tensile stress area, tighter tolerances | High-stress environments (aerospace, military) |

| JIC fittings | 2A/2B UN/UNF | Balance of performance and cost | General applications |

Both AN and JIC fittings use 37° flare fittings. But the thread class and design make a big difference. This matters most when the pressure is high.

Tolerances

Tolerances are very important for how well 37° flare fittings work. AN fittings have much tighter tolerances than JIC fittings. This means AN fittings fit together more exactly. Tight tolerances help stop leaks, especially when the pressure is high. JIC fittings have looser tolerances. This makes them easier and cheaper to make. But they might not be as exact.

- Tolerance differences change how threads fit together.

- AN fittings’ tight tolerances give a safer fit.

- JIC fittings may not be as exact, so leaks can happen in high pressure or important systems.

- You should not mix AN and JIC in places like airplanes or the military because leaks or problems can happen.

Kingdaflex makes both kinds of 37° flare fittings with strong quality checks. You can trust their products for both high pressure and normal jobs.

Material Choices

The material you pick changes how strong and rust-proof 37° flare fittings are. AN fittings usually use top materials like aluminum, stainless steel, or titanium. These make AN fittings light and strong. This is great for high pressure and when you need things to be light. JIC fittings use carbon steel, stainless steel, brass, and sometimes nickel-copper alloys. Stainless steel JIC fittings are good where there are chemicals because they do not rust easily.

Here is a table to help you compare:

| Fitting Type | Common Materials Used | Key Properties |

|---|---|---|

| AN | Aluminum, Stainless Steel, Titanium | Lightweight, corrosion-resistant, high strength |

| JIC | Carbon Steel, Stainless Steel, Brass | Durable, cost-effective, corrosion-resistant |

Pick the material that fits your system’s needs. For high pressure or when weight matters, AN fittings made from aluminum or titanium are best. For normal factory jobs, JIC fittings are a good mix of price and strength.

Flare Angle

Both AN and JIC fittings use a 37° flare angle. This shape makes a metal-to-metal seal that can handle high pressure. You do not need extra parts to seal it. The 37° flare fittings are easy to put together and work well. The flare angle is the same for both, but the way they are made and their tolerances are not.

Some people think AN and JIC fittings are the same because of the flare angle. This is not right. AN fittings are made with tighter tolerances and higher standards. This makes them better for high pressure and important jobs. JIC fittings are fine for normal factory use, but you should not use them instead of AN fittings when safety and performance are very important.

Kingdaflex has many 37° flare fittings, including both AN and JIC types. You can find the right one for your job.

Performance and Application: AN vs JIC

High-Pressure Uses

When you work with hydraulic systems, you need strong fittings. AN fittings are best for high pressure and safety. They use tight tolerances and tough materials like aluminum and stainless steel. You can trust AN fittings in places like airplanes, race cars, and military machines. The 37-degree flare design helps stop leaks, even when pressure is high. O-ring face seal fittings also work well for high-pressure jobs. These fittings press an O-ring into a groove to make a tight seal. This design helps prevent leaks and stops you from tightening too much. For important hydraulic systems, pick AN fittings or O-ring face seal fittings to avoid leaks.

General Industrial Uses

JIC fittings are common in regular industrial hydraulic systems. These fittings give you good value and work well. You can use JIC fittings in many places:

- Machines in factories, like production lines and conveyor belts

- Hydraulic presses and tools, such as pumps and cylinders

- Car hydraulic systems, including brakes and steering

- Military vehicle hydraulic systems in aerospace

JIC fittings are easy to put together and have standard sizes. They are strong and quick to install in hydraulic systems. Kingdaflex sells many JIC fittings for industrial hydraulic jobs.

Automotive and Aerospace

Automotive and aerospace hydraulic systems need high performance and accuracy. AN fittings are light, strong, and very exact. They use materials like aluminum and stainless steel to keep weight low and make them reliable. You see AN fittings in race cars, airplanes, and military vehicles. JIC fittings are also used in car hydraulic systems, but they focus more on saving money and general use.

Here is a table to help you compare AN fittings and JIC fittings in car and airplane hydraulic systems:

| Feature | AN Fittings | JIC Fittings |

|---|---|---|

| Material | Lightweight aluminum, steel, or stainless steel | Many materials for different uses |

| Application | Airplanes, race cars, high-performance vehicles | Factory hydraulics, car systems |

| Weight | Made to be light | Usually heavier and stronger for factories |

| Precision | Very exact for important jobs | More general, not as strict |

Pick AN fittings for high performance and safety in important hydraulic systems. Kingdaflex has both AN and JIC fittings, so you can choose what works best for your hydraulic needs.

Interchangeability and Compatibility

Physical Connection

AN and JIC fittings look almost the same. Both use a 37-degree flare to seal. But their threads and how exact they are make them different. AN fittings have UNJF threads. JIC fittings have UNF threads. These threads seem alike but do not fit together perfectly. Each type has its own thread rules and design. You must check the thread size, pitch, and flare angle before joining parts. JIC fittings do not fit with NPT or BSP types. Even though both have the same flare angle, do not mix them unless you check carefully.

- AN fittings have UNJF threads.

- JIC fittings have UNF threads.

- Both use a 37-degree flare.

- Always check thread details to make sure they fit.

Risks of Mixing

Mixing AN and JIC fittings can cause trouble in your system. Using the wrong parts can make them wear out faster. Hoses and fittings may rub and get damaged quickly. Leaks and failures can happen because the seal is not tight. Different pressure ratings can make weak spots. This can lead to leaks or even system failure. If the materials are not the same, rust or chemical reactions can happen. Bad thread matching can make the connection loose. This could let a hose come off and cause danger.

- More wear and tear from rubbing and pressure changes.

- Leaks and failures are more likely.

- Different pressure ratings can make weak spots.

- Material differences can cause rust.

- Bad thread fit can make connections unsafe.

Note: Always use the right fittings for your system to keep it safe.

Standards Comparison

Industry rules help you know when you can use AN and JIC together. Both have a 37-degree flare seating surface, so sometimes they fit. AN fittings are made with tighter rules and better materials. These are best for planes and military jobs. JIC fittings have looser rules and are used in factories. Sometimes you can swap them in jobs that are not very important, but you must follow the rules. The military made the AN standard to make sure parts fit just right. JIC used the AN standard but made it easier to produce.

- Both have a 37-degree flare seating surface.

- AN fittings are made with tighter rules.

- JIC fittings are based on AN but with easier rules.

- You can swap them in some jobs, but always check the rules.

You should always follow the rules for your system to avoid trouble.

Choosing AN or JIC Fittings

Assessing Needs

First, think about what your system needs. Check how much pressure it will handle. Think about how often you need to fix it. Look at where the system will work. AN and JIC fittings are strong in different ways. AN fittings are best for places with high pressure and lots of shaking. These places include racing and aerospace jobs. JIC fittings are good for regular factory use. They can handle high pressure too. JIC fittings are easier to put in and take care of.

Here is a table to help you compare important things:

| Factor | AN Fittings | JIC Fittings |

|---|---|---|

| System Pressure Requirements | Handles very high pressures | Handles high pressures |

| Sealing and Maintenance Needs | Metal-to-metal seal, reusable | Metal-to-metal seal, reusable |

| Environmental and Vibration | Superior vibration resistance | Good vibration resistance |

| Compatibility with Existing Parts | Matches AN ports | Matches JIC ports |

| Cost and Installation | Higher cost, precise installation | Lower cost, easier installation |

Budget Considerations

Think about how much money you want to spend. AN fittings cost more because they use better materials. They are made with tighter rules. JIC fittings cost less but still work well for many jobs. If you want to save money and do not need the best fit, pick JIC fittings. Kingdaflex sells both types. You can find fittings that match your budget and needs.

Manufacturer Guidelines

Always look at what the maker says for your system. The rules help you pick the right fittings for pressure, space, and how parts connect. AN fittings fit well in small spaces. They are easy to connect. JIC fittings may need more room and extra parts. They give you more ways to change things. Makers often say to use AN fittings for important systems. They suggest JIC fittings for regular hydraulic jobs.

Here is a table to help you choose:

| Consideration | AN Fittings | JIC Fittings |

|---|---|---|

| Pressure requirements | Best for high-pressure systems | Good for most hydraulic applications |

| Available space | Compact solution | Needs more space |

| Complexity of connection | Simple, direct connection | Flexible, allows changes |

| Cost factors | Higher cost | Lower cost |

Kingdaflex has many AN and JIC fittings. You can trust their products to work well and last long, no matter what your system needs.

Consequences of Wrong Selection

Performance Impact

If you pick the wrong fitting, your hydraulic system can have problems. Leaks might happen and make the pressure drop. When pressure drops, parts like actuators move slower or stop early. The system may use more energy to keep working. This makes power bills go up and pumps wear out faster. If you mix AN and JIC fittings or use the wrong parts, hoses can burst. This can cause the system to stop working without warning. About 30% of hose problems come from using the wrong fittings or not following the right rules. Hose bursts can cause almost half of all surprise shutdowns. These shutdowns can cost hundreds or thousands of dollars every hour.

- Mixing different fittings can cause leaks, hose bursts, and stops.

- Lower pressure means machines work slower.

- Using more energy costs more money and wears out parts.

Safety Issues

Using the wrong fittings can make things unsafe. Leaking hydraulic fluid can make floors slippery. This can cause people to slip and get hurt. If the fluid can catch fire, leaks near hot spots or sparks can start fires. In one factory, a worker got badly hurt by a high-pressure fluid leak. He tried to find the leak with his hand and got sprayed. He needed a lot of medical help. This shows why it is important to pick and install fittings the right way. Using the wrong parts can make machines break and put people in danger.

Cost Risks

Choosing the wrong fittings can make repairs and upkeep cost more. Leaks waste fluid and make the system work worse. If fittings are not put in right, pressure can drop and the system will not work well. Bad fittings can break other parts and make repairs expensive. If things break often, you lose time and spend more money. In North America, hose bursts can cost $700 to $3,500 every hour the system is down. In Europe, not following safety rules can make repairs cost over €12,000 each time.

| Issue | Description |

|---|---|

| Leaks | Wrong fittings can cause leaks, wasting fluid and making the system weaker. |

| Pressure Loss | Bad installation can lower pressure and make the system work poorly. |

| Damage to Components | Bad fittings can break other parts, making repairs cost more. |

| Frequent Breakdowns | Not taking care of fittings can cause more breakdowns and cost extra money. |

You can easily spot how AN and JIC fittings are different. The table below helps you compare their sizing, rules, materials, and price:

| Feature | JIC Fittings | AN Fittings |

|---|---|---|

| Sizing System | Uses fractional sizes | Uses number sizes |

| Industry Standards | Follows SAE J514 rules | Follows military rules |

| Material and Finish | Made from carbon steel, stainless steel, or brass | Made from aluminum, stainless steel, or titanium |

| Applications | Used in many hydraulic systems | Used in aerospace, cars, and racing |

| Cost | Costs less | Costs more |

Pick the right fitting to keep your system safe and working well. If you are not sure, ask experts or trusted suppliers like Kingdaflex.

- Experts help you choose fittings for your system’s pressure and fluid.

- Good advice can help you save time and money.