We supply Beam Seal hydraulic fittings, engineered for the most demanding high-pressure, high-temperature, and zero-leak applications, especially prevalent in aerospace and defense. These advanced metal-to-metal seals offer exceptional reliability, resistance to vibration, and reusability, minimizing maintenance and maximizing system uptime. Contact us for wholesale solutions that ensure ultimate fluid containment and performance.

Offer your clients the pinnacle of hydraulic reliability with our wholesale beam seal hydraulic fittings. Designed for aerospace and critical applications, these zero-leak, high-pressure fittings guarantee superior performance and extreme temperature resistance. Provide unmatched durability and confidence, minimizing callbacks and maximizing client satisfaction. Partner with us to supply a solution that truly delights through unwavering quality.

We offer Beam Seal fittings in a variety of high-performance materials, allowing for customization based on application demands. This includes robust stainless steel for superior corrosion resistance and high-strength alloys for extreme pressure and temperature environments. Material selection directly impacts the fitting’s durability, chemical compatibility, and overall lifespan, ensuring it can withstand specific operational challenges.

We offer a wide array of customization options for connection end configurations. This allows us to integrate Beam Seal technology with various industry-standard and proprietary interfaces, such as NPT, BSPP, JIC, or specialized aerospace connections. Tailoring the ends ensures perfect compatibility with your existing tubing, hoses, and components, simplifying installation and reducing the need for adapters, thereby streamlining your system design.

We offer customization of Beam Seal fittings to meet precise pressure and temperature requirements. This involves engineering the fitting’s geometry and selecting specific materials capable of withstanding the exact operational parameters of your hydraulic system. Whether you need fittings for cryogenic temperatures or super-high pressures, our tailored solutions ensure peak performance and safety without compromise, preventing leaks and failures.

We offer specialized surface finishes and treatments for Beam Seal fittings. This includes passivation for enhanced corrosion resistance, unique coatings for reduced friction, or specific surface hardness treatments for increased wear resistance. These customizations can significantly extend the fitting’s operational life, improve its sealing performance in challenging environments, and meet stringent industry cleanliness or aesthetic standards.

We offer high-performance beam seal swivel female hydraulic fittings, engineered for critical applications demanding flexibility and zero leakage. These specialized fittings combine the superior sealing of Beam Seal technology with a robust swivel capability, allowing for rotational movement without compromising seal integrity. Ideal for dynamic systems, they provide exceptional reliability and ease of installation in challenging,

We offer Beam Seal Male x BSPT Male Adapters, providing a robust solution for critical hydraulic connections. These adapters combine the superior, zero-leak performance of a Beam Seal with the widely used British Standard Pipe Tapered thread, ensuring secure and reliable transitions. Ideal for demanding applications, our fittings are engineered for high pressure, high temperature, and exceptional durability.

We offer beam seal test hydraulic fittings, essential for verifying the integrity and performance of critical fluid systems. These specialized fittings are designed to integrate seamlessly into test setups, allowing for precise pressure, leak, and burst testing of beam seal connections. Our robust test fittings ensure accurate diagnostics and compliance with rigorous aerospace and industrial standards, guaranteeing the reliability of your hydraulic components.

We offer beam seal hydraulic fitting adapters, precisely engineered to bridge critical beam seal connections with other standard hydraulic interfaces. These adapters ensure a seamless, zero-leak transition between different thread types or components. Ideal for specialized aerospace and defense applications, our adapters maintain the high-pressure, high-temperature, and extreme reliability inherent to beam seal technology, optimizing system integration and performance.

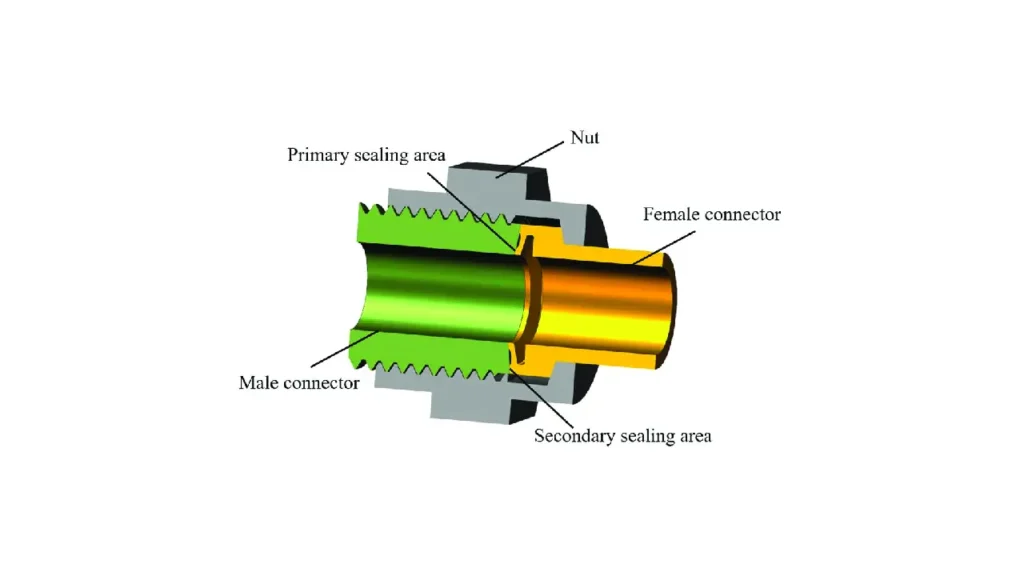

A beam seal for hydraulic fittings is a highly specialized, metal-to-metal sealing mechanism designed for extreme conditions found primarily in aerospace, defense, and other mission-critical applications.

Unlike seals that rely on elastomeric O-rings, the beam seal achieves a zero-leak connection through the precise deformation and loading of its metallic sealing elements, often described as an “elastic beam” or lip.

This innovative design ensures unparalleled reliability against high pressures (e.g., 3000-8000 psi per SAE AS85421 and AS85720 standards), extreme temperatures, and severe vibration, even after repeated assembly and disassembly.

A beam seal hydraulic fitting is a highly specialized, metal-to-metal sealing connector designed for extremely demanding applications where zero leakage is paramount. Unlike fittings that rely on elastomeric O-rings for sealing, the beam seal achieves its robust seal through the controlled elastic deformation of a precisely engineered metallic “beam” or lip integrated into the fitting.

This design allows it to maintain a perfect seal under severe conditions of high pressure, extreme temperature fluctuations, and intense vibration, making it a critical component in aerospace, defense, and other mission-critical hydraulic systems.

Beam seal hydraulic fittings are specifically designed for applications where absolute leak integrity, extreme reliability, and performance under severe operating conditions are non-negotiable.

Their robust metal-to-metal sealing mechanism, often specified by standards like SAE AS85421 (3000/4000 psi) and AS85720 (5000/8000 psi), makes them ideal for environments where a traditional O-ring could fail due to high temperature, pressure, vibration, or aggressive fluids.

Their primary applications include:

Choosing our hydraulic fittings ensures superior system performance and reliability, backed by our commitment to quality and precision engineering. We understand the critical role these components play in preventing leaks, maintaining pressure, and safeguarding your operations.