Choosing the right fitting is crucial for reliable fluid systems. Compression and flare fittings are common choices, but they operate differently and excel in specific applications. Understanding their distinctions prevents leaks and ensures system integrity.

This guide will thoroughly compare compression and flare fittings. We’ll explore their unique sealing mechanisms, installation methods, and ideal uses. Learn which fitting is best suited for your next plumbing or hydraulic project.

What are Compression Fittings

Compression fittings are a type of coupling used in plumbing and fluid systems to join two pipes or a pipe to a fixture or valve without soldering, welding, or flaring. They typically consist of three parts: a compression nut, a compression ring (often called a ferrule or olive), and the fitting body.

When the nut is tightened, it compresses the ring onto the pipe’s outer diameter and into the fitting body, creating a tight, leak-proof seal. They are valued for their ease of installation and disassembly, making them suitable for low to medium-pressure applications in various materials like copper, plastic, and stainless steel.

What are Flare Fittings

Flare fittings are a type of mechanical connection used in fluid systems to create a leak-tight seal by flaring the end of a tube and then compressing it against a matching conical seat on the fitting body.

They typically consist of a fitting body with a tapered seat, a flare nut, and sometimes a sleeve. This design relies on a metal-to-metal seal, making them highly reliable for high-pressure applications in industries such as hydraulics, refrigeration, and automotive fuel and brake lines.

Compression Fitting vs Flare

Choosing between compression and flare fittings is key for fluid systems. Both create secure connections, but their distinct designs dictate optimal use. Understanding their core differences ensures leak-free, reliable performance for your specific application needs.

Sealing Mechanism

Compression fittings seal by compressing a ferrule (ring) onto the tube and into the fitting body. The tightening action deforms the ferrule, creating a tight mechanical seal against both the tube’s outer diameter and the fitting’s conical seat, preventing fluid escape.

Flare fittings, conversely, create a metal-to-metal seal by flaring the end of the tube to a specific angle (e.g., 37° JIC, 45° SAE). This flared end then mates with a corresponding conical seat on the fitting body when tightened, ensuring a robust seal.

Installation

Compression fittings are generally easier to install, requiring no specialized flaring tools. The process involves inserting the tube and tightening a nut, which compresses the ferrule. This simplicity makes them ideal for quick repairs and DIY projects.

Flare fitting installation demands more precision and a flaring tool to create the perfect flare angle. Incorrect flaring can lead to leaks. While requiring more skill, a properly flared connection offers strong, durable seals suitable for demanding applications.

Reusability

Compression fittings, especially those with single-use ferrules, are often not recommended for reuse. Once a ferrule is compressed, it deforms to the tube, and re-tightening might not provide the same seal integrity, potentially leading to leaks over time.

Flare fittings, if the flare and fitting body are undamaged, are generally reusable. The metal-to-metal seal is less prone to permanent deformation than a compression ferrule. This reusability makes them advantageous for systems requiring frequent disassembly or maintenance.

Pressure Rating/Applications

Compression fittings typically suit low to medium-pressure applications, common in residential plumbing, instrumentation, and some automotive lines. Their sealing mechanism is less robust under very high pressures or significant vibration compared to flared connections, limiting their use.

Flare fittings are designed for higher-pressure applications, making them prevalent in hydraulic systems, refrigeration, and fuel lines. Their strong metal-to-metal seal can withstand greater pressures and vibrations, offering superior reliability in demanding industrial environments.

Tube Preparation

Compression fittings require precise cutting of the tube, ensuring a clean, burr-free end. The tube does not need to be shaped or flared. Proper deburring is crucial to prevent damage to the ferrule during compression and ensure an effective seal.

Flare fittings demand specific tube preparation beyond just cutting. The tube end must be precisely flared to the correct angle using a specialized flaring tool. This shaping is fundamental to forming the sealing surface, making tube preparation more involved.

Here is a comparison table summarizing the differences between compression fittings and flare fittings:

| Feature | Compression Fittings | Flare Fittings |

| Sealing Method | Ferrule compression onto tube | Metal-to-metal contact via flared tube |

| Installation | Easier, no specialized flaring tool | Requires flaring tool, more precise |

| Reusability | Generally not reusable (ferrule) | Generally reusable (if undamaged) |

| Pressure Range | Low to medium pressure | High pressure |

| Tube Prep. | Cut, deburr | Cut, deburr, and flare (specific angle) |

How to Choose Compression and Flare Fittings?

Choosing between compression and flare fittings depends on your specific application’s demands for pressure, ease of installation, and reusability. Understanding their core differences in sealing mechanisms and operational strengths is paramount to ensuring a secure, leak-free, and long-lasting connection for your fluid transfer system, ultimately optimizing performance and safety.

Here are 5 key considerations when choosing:

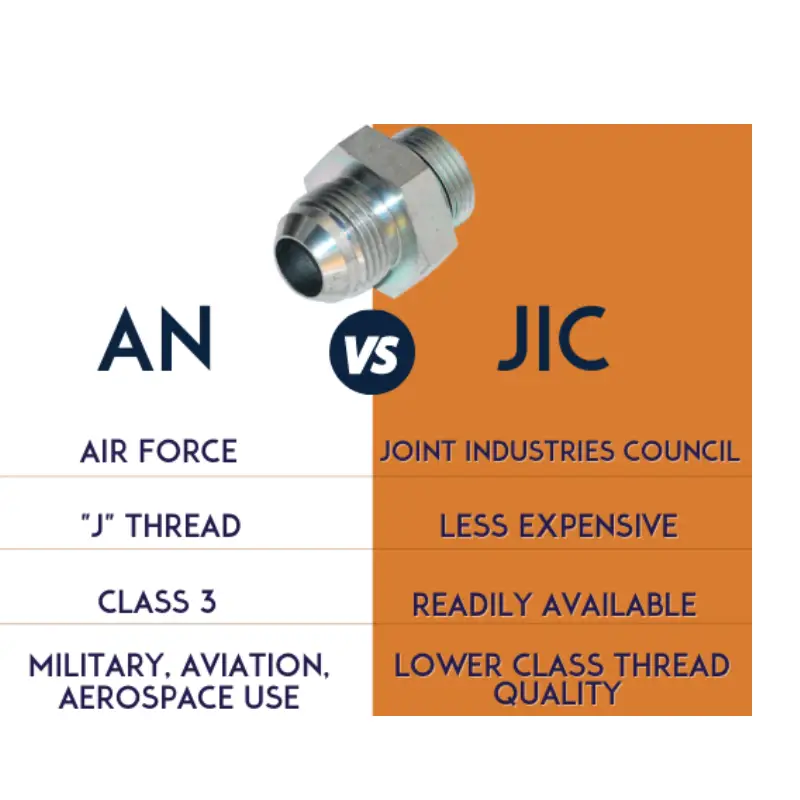

- Pressure Requirements: Evaluate the maximum operating pressure of your system. Flare fittings (e.g., JIC 37°) are typically preferred for high-pressure hydraulic applications due to their robust metal-to-metal seal, offering superior reliability under demanding conditions.

- Hydraulic Fitting Installation Skill & Tools: Consider the installer’s experience and available tools. Compression fittings are generally simpler and quicker to install without specialized flaring tools, making them ideal for DIY or quick repairs, whereas flare fittings require precision flaring equipment.

- Reusability Needs: Determine if the connection will require frequent disassembly. Flare fittings are generally reusable if the flare and fitting body remain undamaged, making them suitable for systems needing regular maintenance. Compression fittings, especially the ferrule, are often single-use.

- Vibration and Movement: Assess the level of vibration or movement the connection will experience. Flare fittings often provide a more secure and durable connection in dynamic environments compared to compression fittings, which might loosen over time under constant stress.

- Fluid Type & Temperature: Consider the type of fluid being transferred and the operating temperature. Ensure the fitting material and sealing method are compatible with the fluid’s chemical properties and can withstand the temperature range without degradation or leakage.

Conclusion

Understanding the distinct differences between compression and flare fittings is vital for any fluid system project. Each offers unique advantages in sealing and application, making the correct choice paramount for performance and safety.

By considering factors like pressure, reusability, and installation complexity, you can confidently select the ideal fitting type for your specific needs. This informed decision ensures a reliable, leak-free connection, saving time and resources.

For high-quality compression and flare fittings that meet rigorous standards, consider where to get wholesale hydraulic fittings from trusted Kingdaflex hydraulic fitting manufacturer. We offer a wide range to ensure you have the right components for every project.