Kingdaflex: Your One-Stop Shop for High-Quality Hydraulic Hose Flange Fittings. Secure, reliable connections for optimal hydraulic system performance. Get a quote today!

Kingdaflex, we are a Reliable Hydraulic Flange Fitting Manufacturer. Get high-quality, cost-effective flange fittings for secure connections in your hydraulic systems.

Base Metal: Choose from various materials like steel (different grades for pressure and temperature resistance), stainless steel (corrosion resistance), or even brass (for lower pressure applications).

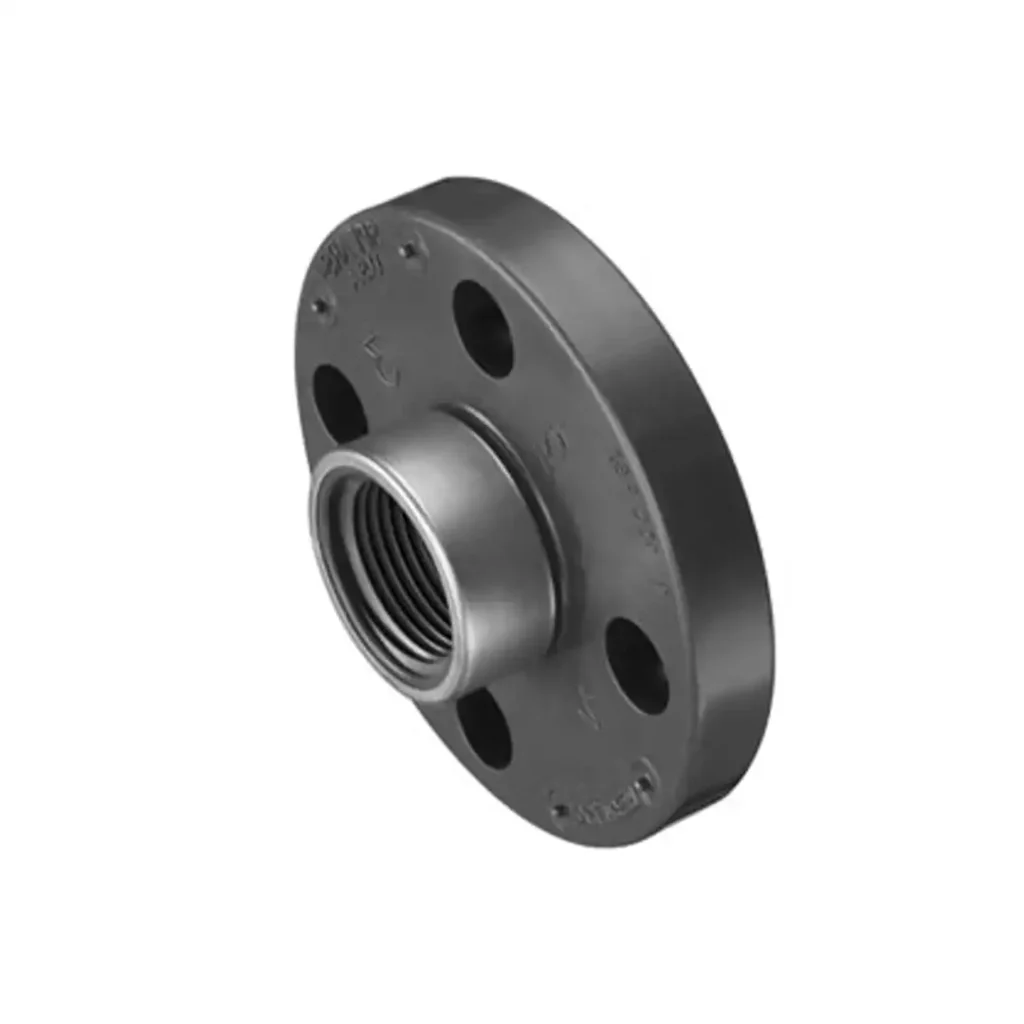

Also known as 4-bolt flanges. Most popular type due to their versatility and secure bolting pattern.

Available in two pressure ratings:

Similar to a high-pressure Code 62 flange but with a thicker flange body for added strength. Primarily used with Caterpillar equipment but may be compatible with other high-pressure applications.

Combine the hose fitting and flange into a single unit. Offer a compact design but limit customization options compared to separate hose fittings and flanges.

Integrate a 90-degree bend into the flange design, reducing the need for additional elbows in the hose assembly. Useful for tight spaces or situations where a change in direction is required near the connection point.

Hydraulic hose flange fittings are widely used in construction equipment due to their ability to handle high pressures and vibrations. They are used for connecting hydraulic lines to components like actuators, cylinders, and pumps.

Hydraulic systems are essential in modern agricultural machinery . Flange fittings play a crucial role here by ensuring leak-free connections in equipment like tractors, harvesters, and plows. They are built to withstand harsh environmental conditions and heavy-duty use.

Flange fittings are used in various machine tools such as excavators, bulldozers, and cranes. They provide secure connections for hydraulic systems that power functions like movement of arms, lifting mechanisms, and tool operation.

In the oil and gas industry, flange fittings are used for high-pressure applications such as drilling rigs and hydraulic fracturing equipment. They are made from robust materials like stainless steel to handle extreme pressures and corrosive fluids.

A flange fitting is a specific type of connector used to join pipes, valves, pumps, and other equipment in applications that involve fluids.

Here’s a breakdown of its key features:

Function:

When selecting a hydraulic hose flange fitting, consider these factors:

By understanding the different types of hydraulic hose flange fittings and their characteristics, you can choose the most suitable option for your specific application, ensuring a secure, leak-proof, and high-performing hydraulic system.

Measuring a hydraulic flange fitting accurately ensures you get the perfect replacement part for a leak-free and secure connection. Here’s how to measure the key aspects of a hydraulic flange fitting:

Tools you’ll need:

Calipers (ideally dial or digital for better precision)

Tape measure (for overall length, if needed)

What to measure:

Flange Diameter (Dimension F):

Use the calipers in the diameter mode to measure the widest part of the flange itself, not including the bolt holes.

Flange Thickness (Dimension C):

Close the calipers on the flange’s edge to measure its thickness. This helps identify the specific flange type (e.g., standard vs. high-pressure).

Port size (diameter):

There are two ways to approach this depending on the fitting type:

Thread type:

While not strictly a measurement, identify the thread type (e.g., NPT, BSP) for proper compatibility with the hose and component you’re connecting. This information is often stamped on the fitting or found in manufacturer specifications.

Overall Length (optional):

If needed, use a tape measure to determine the entire length of the fitting, from the end of the threads (or flange face) to the opposite end.

Tips for accurate measuring:

By following these steps and using the appropriate tools, you can accurately measure your hydraulic flange fitting and ensure a proper, leak-proof connection in your hydraulic system.

Installing a hydraulic flange fitting involves creating a secure and leak-proof connection between a hose and a flanged component. Here’s a general guideline, but always refer to the specific manufacturer‘s instructions for your particular fitting:

Safety Precautions:

Pressure relief: Ensure the hydraulic system is depressurized before starting any work. Release any pressure in the lines and bleed any residual pressure from the component.

Proper tools: Use the correct wrenches or sockets with the recommended size for the fitting’s bolts. Avoid using adjustable wrenches, as they can damage the bolt heads.

Eye protection: Wear safety glasses to protect your eyes from debris or potential fluid spray during installation.

Materials:

Steps:

Prepare the Hose:

Prepare the Flange:

Assemble the Connection:

Tighten the Bolts:

Final Inspection:

Do not overtighten in an attempt to stop leaks. If a leak persists, disassemble the connection and check for a damaged gasket or hose.

Additional Tips:

Remember, these are general guidelines. Always prioritize safety and follow the specific instructions provided by the manufacturer of your chosen hydraulic flange fitting for a successful installation.