When designing or repairing fluid systems, selecting the correct fitting is paramount for safety and efficiency. Two prevalent types, Inverted Flare and O-Ring fittings, offer distinct advantages. While both ensure leak-free connections, their fundamental sealing mechanisms and ideal applications differ significantly.

This comparison will delve into the core characteristics of each fitting, highlighting their design, performance capabilities, and typical uses. Understanding these differences is crucial for engineers, mechanics, and DIY enthusiasts to make informed decisions that guarantee system integrity.

What is Inverted Flare?

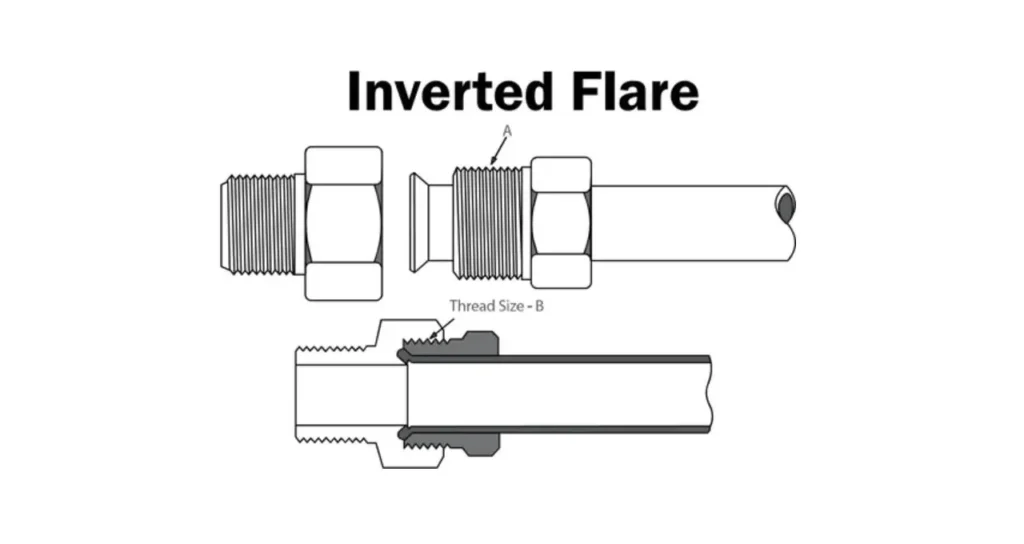

An inverted flare is a specific type of tubing connection, widely used in automotive, refrigeration, and hydraulic systems. It involves flaring the end of a tube inward to create a conical shape. This inverted cone then seats precisely into a corresponding concave, conical surface within the fitting.

When the connecting flare nut is tightened, it compresses the flared tube against the fitting’s seat, establishing a robust, metal-on-metal seal that is highly resistant to leaks and vibrations, making it ideal for high-pressure and dynamic fluid transfer applications.

What is an O-ring?

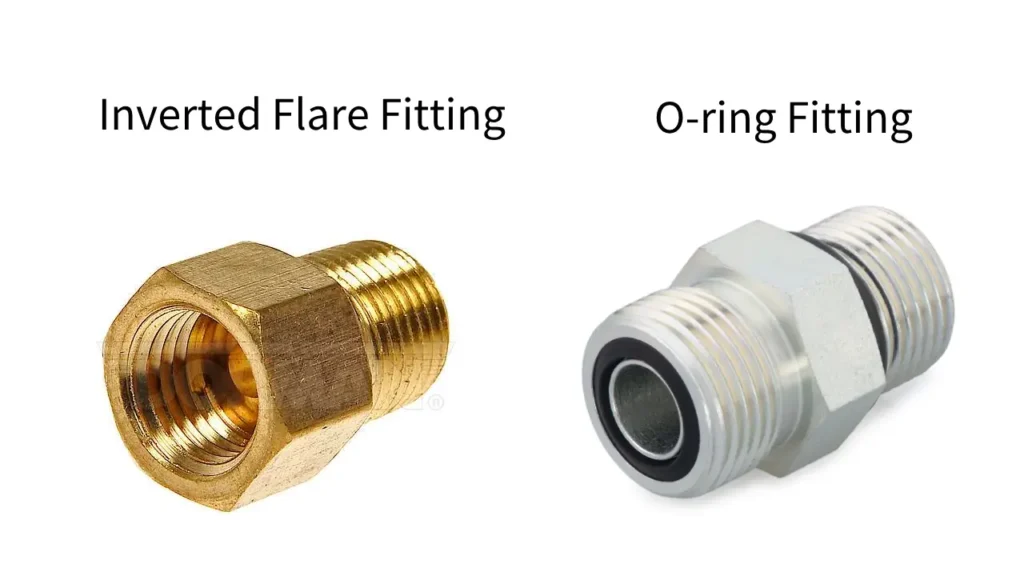

An O-ring is a simple, yet highly effective mechanical gasket, typically a circular loop of elastomer (rubber) with a round cross-section. Its primary function is to create a leak-proof seal between two or more parts when compressed within a specially designed groove.

When assembled, the O-ring deforms to fill any imperfections or gaps at the interface, blocking the passage of fluids or gases. Widely used in both static and dynamic applications, O-rings are popular due to their low cost, ease of installation, and reliable sealing across a broad range of pressures and temperatures.

Inverted Flare vs O-Ring

In selecting fluid connectors, the choice between Inverted Flare and O-Ring fittings is critical. These two common types employ fundamentally different sealing methods, influencing their suitability for various applications, pressure levels, and environmental conditions.

Sealing Mechanism

Inverted flare fittings achieve their seal through a precise metal-on-metal compression. The end of the tubing is flared inward to form a conical shape, which then mates perfectly with a corresponding concave seat within the fitting. When the flare nut is tightened, it forces this flared surface against the seat, creating a robust, leak-tight barrier that requires no additional sealants.

O-ring fittings, on the other hand, rely on the controlled deformation of an elastomeric (rubber) O-ring. The O-ring is seated in a specially designed groove, and when the two mating components are brought together and tightened, the O-ring is compressed. This compression causes the O-ring to fill any microscopic gaps or imperfections, creating a secure seal against fluid or gas leakage.

Design and Components

Inverted flare fittings typically consist of a fitting body with a conical seat and a flare nut that slides over the tubing. The tubing itself must be specifically flared to match the fitting’s angle (commonly 45 degrees). The threads on the flare nut and the fitting primarily serve to apply clamping force, not to create the seal.

O-ring fittings often feature a male connector with an O-ring groove and a corresponding female port with a flat or chamfered sealing surface. The O-ring material varies widely (e.g., Nitrile, Viton, EPDM) depending on the fluid compatibility, temperature range, and pressure requirements. The threads on O-ring fittings are usually straight, ensuring mechanical retention rather than sealing.

Common Applications

Inverted flare fittings are extensively used in automotive applications, including brake lines, fuel lines, and power steering systems, as well as in some refrigeration and HVAC systems. Their metal-on-metal seal offers excellent vibration resistance and reliability in dynamic environments where a hard, unyielding seal is desired and contamination from sealants is undesirable.

O-ring fittings are ubiquitous across many industries, including hydraulics, pneumatics, plumbing, and medical devices. They are particularly favored in situations where a highly effective and long-lasting seal is needed against a wide array of fluids, and where the system experiences less extreme vibration compared to some automotive applications. Examples include cylinder seals, valve stems, and pipe connections.

Installation Requirements

Installing an inverted flare connection requires preparing the tubing by cutting, deburring, and then creating a precise flare using a specialized flaring tool. The flare nut is then tightened to compress the flare into the seat. Proper flaring technique and torque are critical to avoid damaging the flare or creating a weak seal.

O-ring installation typically involves placing the O-ring into its designated groove, applying a lubricant (compatible with the O-ring material and fluid) to ease assembly and prevent pinching, and then assembling the components. The design of the groove and the O-ring’s compression ensure the seal, and proper sizing is essential to prevent extrusion or insufficient sealing.

Pressure Handling

Inverted flare fittings are known for their robust performance in high-pressure applications, capable of withstanding significant pressures in hydraulic and brake systems due to their direct metal-on-metal compression seal. Their inherent strength resists blowouts and maintains integrity even under fluctuating pressures.

O-ring fittings can also handle very high pressures, especially in static applications, provided the O-ring material is suitable and the groove design prevents extrusion. However, in dynamic applications or with very high pressures, specialized O-ring types or backup rings may be necessary to prevent the O-ring from extruding into the clearance gap under pressure.

| Aspect | Inverted Flare | O-Ring |

| Sealing Mechanism | Metal-on-metal compression of flared tube against seat | Elastomeric O-ring deforms in groove |

| Components | Flared tube, flare nut, fitting with conical seat | O-ring, male connector with groove, female port with flat/chamfer |

| Common Applications | Automotive brake/fuel lines, hydraulics, refrigeration | Hydraulics, pneumatics, general plumbing, medical devices |

| Vibration Resist. | Excellent | Good (static), can be prone to wear in high dynamic vibration |

| Sealant Required? | No | No (but lubricant often used for installation) |

| Reusability | Good, if flare remains undamaged | Good, if O-ring not damaged or deformed; O-ring replacement often recommended |

| Pressure Handling | Very High (due to metal-on-metal seal) | High (design dependent, can extrude without backup rings at extreme pressures) |

Considerations about Inverted Flare and O-ring

When deciding between Inverted Flare and O-ring fittings, several critical considerations should guide your choice to ensure system reliability and safety. The specific demands of your application, including the type of fluid, operating environment, and maintenance protocols, will heavily influence which fitting type is most appropriate.

- Vibration and Movement: Inverted flares offer superior resistance to vibration and continuous movement, making them ideal for automotive and mobile hydraulic systems where dynamic stresses are common. O-ring seals, while robust, can experience wear or extrusion over time in highly vibratory conditions.

- Pressure and Temperature: Both can handle high pressures, but inverted flares excel in extreme pressure applications, especially where metal fatigue is a concern. O-rings’ temperature limits are dictated by their elastomer material, which can degrade at very high or low temperatures, potentially leading to leaks.

- Fluid Compatibility: O-rings require careful selection of material to ensure compatibility with the fluid being transferred (e.g., fuel, brake fluid, oil) to prevent degradation and swelling. Inverted flares, being metal-on-metal, generally have broader fluid compatibility limited only by the tubing and fitting material.

- Ease of Assembly and Disassembly: Inverted flares require specialized tools for tubing preparation (flaring) and precise tightening. O-rings are often simpler to install, but proper groove design and O-ring lubrication are crucial. For frequent disassembly, the reusability of a well-maintained flare can be an advantage, though O-rings are easily replaceable.

- Contamination Risk: Inverted flares offer a clean, metal-on-metal seal, avoiding the potential for elastomeric particles from O-rings to contaminate sensitive fluids, which can be a concern in some precision hydraulic or medical applications.

Conclusion

Choosing the right fluid connection, whether an Inverted Flare or an O-ring fitting, is crucial for maintaining system integrity and safety. Each design offers distinct advantages suited to different operating conditions, particularly concerning sealing effectiveness and resistance to environmental factors.

Inverted flares excel in high-vibration applications and where a robust metal-on-metal seal is critical, such as in automotive brake lines. O-Ring fittings, conversely, offer superior sealing capabilities against a wider range of fluids and pressures, especially in static or low-vibration environments where their elastomer seal can perform optimally.

For a comprehensive selection of hydraulic fittings, including both Inverted Flare and O-Ring types, consider Kingdaflex. Their extensive inventory ensures you’ll find the perfect solution for your specific hydraulic system needs, guaranteeing reliable and leak-free performance.