Proper disposal and recycling of rubber hoses are essential for environmental protection and sustainable practices. Rubber hoses, used in industrial, automotive, and garden applications, often contain materials that require careful handling to prevent pollution and reduce landfill waste effectively.

Recycling old or damaged rubber hoses not only minimizes environmental impact but also creates opportunities to repurpose materials for new products. By following safe disposal and recycling guidelines, businesses and individuals can contribute to sustainability while ensuring compliance with local regulations and maintaining workplace safety.

Are Rubber Hoses Recyclable?

Yes, rubber hoses are recyclable, though the process can vary depending on the type of rubber and local recycling facilities. Many hoses, especially those made from natural or synthetic rubbers, can be processed into crumb rubber, mats, or other industrial products, reducing environmental waste.

Recycling rubber hoses helps conserve resources, minimizes landfill accumulation, and can provide materials for new products such as flooring, playground surfaces, or automotive parts. Proper sorting, cleaning, and preparation are essential to ensure effective recycling and to maintain the quality of the recycled rubber for future applications.

How to Dispose of Rubber Hoses?

Proper disposal of rubber hoses is essential to reduce environmental impact and promote sustainability. Rubber hoses from industrial, automotive, or garden use can be recycled, repurposed, or disposed of responsibly. Following safe disposal methods ensures compliance with regulations, minimizes landfill waste, and contributes to environmentally-friendly practices while maintaining workplace and public safety.

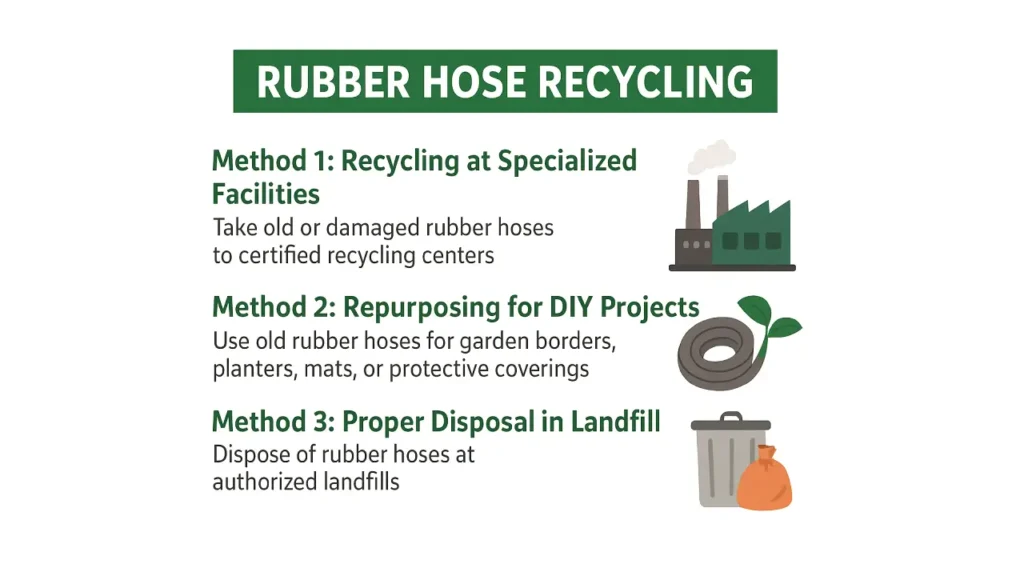

Method 1: Recycling at Specialized Facilities

Take old or damaged rubber hoses to certified recycling centers that accept rubber products. These facilities process hoses into crumb rubber or other materials for reuse. By recycling at specialized centers, you ensure the rubber is repurposed safely, reducing environmental pollution and conserving natural resources.

Before recycling, clean hoses thoroughly to remove debris, oils, or chemicals. Cut hoses into manageable sections for easier handling and processing. Proper preparation enhances recycling efficiency and prevents contamination, ensuring that the resulting recycled material meets quality standards for new industrial or consumer products.

Method 2: Repurposing for DIY Projects

Old rubber hoses can be creatively repurposed for garden borders, planters, mats, or protective coverings. This method extends the hose’s life, reduces waste, and provides cost-effective solutions for personal or community projects.

Ensure hoses are safe for intended repurposed use, avoiding those exposed to harmful chemicals. Proper cutting, cleaning, and securing allow hoses to be used effectively in projects while preventing injuries, leaks, or environmental hazards, making repurposing both practical and eco-friendly.

Method 3: Proper Disposal in Landfill

If recycling or repurposing is not feasible, dispose of rubber hoses at authorized landfills that accept industrial rubber products. Proper disposal ensures compliance with local regulations and prevents environmental contamination.

Before disposal, cut hoses into smaller pieces to minimize space and facilitate handling. Avoid mixing with hazardous waste or non-recyclable materials, and follow local guidelines to ensure safe landfill disposal that reduces potential risks to soil, water, and surrounding ecosystems.

Tips for Rubber Hose Recycling

Recycling rubber hoses effectively requires proper preparation, sorting, and handling to ensure environmental safety and material quality. Following best practices maximizes the potential for reuse, reduces waste, and supports sustainable solutions in industrial, automotive, marine, and garden applications.

- Clean Hoses Thoroughly: Remove dirt, oils, chemicals, or debris from hoses before recycling to prevent contamination and ensure high-quality recycled material suitable for industrial or consumer products.

- Cut into Manageable Sections: Segment hoses into smaller pieces to simplify handling, transportation, and processing, making recycling operations more efficient and reducing risks of damage or operational delays.

- Sort by Material Type: Separate hoses by rubber type or reinforcement to optimize recycling processes, ensuring the resulting materials meet quality standards for reuse or industrial applications.

- Use Certified Recycling Centers: Always choose authorized facilities experienced in rubber recycling to guarantee proper processing, environmental compliance, and safe disposal of residual waste.

- Consider Repurposing Options: Explore creative reuse of old hoses for garden projects, protective coverings, or mats to extend lifespan before recycling, reducing waste and saving costs.

Conclusion

Responsible disposal and recycling of rubber hoses help protect the environment while reducing waste in landfills. By repurposing or recycling old hoses, you can promote sustainability and extend the life cycle of rubber materials efficiently. Following proper guidelines ensures safety and compliance in all applications.

For businesses needing multiple hoses, obtaining wholesale rubber hoses from Kingdaflex is a cost-effective solution. We offer high-quality hoses in various sizes, materials, and specifications to meet industrial, automotive, marine, and agricultural requirements. Our hoses are durable, flexible, and resistant to heat, oil, chemicals, and abrasion.

Choosing Kingdaflex for your rubber hose supply ensures consistent quality, timely delivery, and professional support. Whether for new installations or replacements, our wholesale options provide reliable, long-lasting hoses that meet diverse operational needs while helping you maintain efficiency and reduce environmental impact.