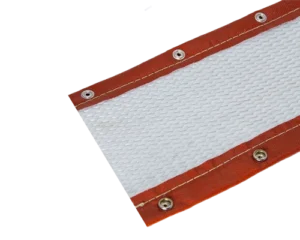

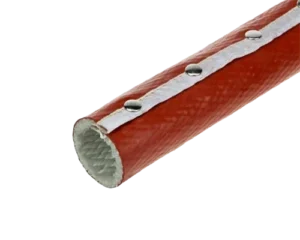

Material: Silicone, fiberglass.

Key Features: This type utilizes heavy-duty metal snap buttons (typically spaced 4 or 6 inches apart) for a secure mechanical lock. It is specifically engineered to outperform hook-and-loop closures in demanding conditions involving heavy welding spatter and intense liquid metal splash.

Performance & Applications: Designed for extreme environments where physical abuse is a concern, such as near foundries and heavy welding stations. It provides reliable protection where other sleeves might fail. The snaps allow for easy on-site installation and adjustment.

Structural Advantage: Offers a robust balance between the durability of a tube-style sleeve and the installability of a wrap-around design. Additional snaps can be added in the field to accommodate unique bends or enhance closure security.

Temperature Range: 260°C – 1650°C; Continuous operating temperature: 500°F (260°C); Max short term exposure: 3000°F (1650°C).

| Product | Inside dia. | Inside dia. | Wall thickne ss | Tolerance | Roll length | Ctn size | No./ctn | G.W. |

| mm | inch | mm | mm | m | cm | m | kg | |

|

Φ6 | 1/4=PJ04 | 1.5 | ±0.15 | 50 | 47*47*10 | 100 | 22.0 |

| Φ8 | 5/16=PJ05 | 1.5 | ±0.15 | 50 | 47*47*10 | 100 | 24.5 | |

| Φ10 | 3/8=PJ06 | 2 | ±0.20 | 25 | 47*47*10 | 100 | 28.0 | |

| Φ11 | 7/16=PJ07 | 2 | ±0.20 | 25 | 47*47*10 | 100 | 29.5 | |

| Φ13 | 1/2=PJ08 | 2 | ±0.20 | 25 | 47*47*10 | 100 | 30.2 | |

| Φ16 | 5/8=PJ10 | 2 | ±0.20 | 25 | 47*47*10 | 50 | 16.5 | |

| Φ19 | 3/4=PJ12 | 2 | ±0.20 | 25 | 47*47*10 | 50 | 20.4 | |

| Φ22 | 7/8=PJ14 | 2 | ±0.20 | 25 | 47*47*10 | 50 | 21.5 | |

| Φ25 | 1=PJ16 | 2 | ±0.30 | 25 | 47*47*10 | 50 | 24.5 | |

| Φ29 | 1 1/8=PJ18 | 2 | ±0.30 | 25 | 47*47*10 | 50 | 25.5 | |

| Φ32 | 1 1/4=PJ20 | 2 | ±0.30 | 25 | 47*47*10 | 50 | 27.5 | |

| Φ35 | 1 3/8=PJ22 | 3 | ±0.30 | 25 | 47*47*15 | 50 | 28.5 | |

| Φ38 | 1 1/2=PJ24 | 3 | ±0.30 | 25 | 47*47*15 | 50 | 34.0 | |

| Φ40 | 1 3/5=PJ24 | 3 | ±0.30 | 25 | 47*47*15 | 50 | 34.5 | |

| Φ41 | 1 5/8=PJ26 | 3 | ±0.30 | 25 | 47*47*15 | 50 | 35.0 | |

| Φ45 | 1 3/4=PJ28 | 3 | ±0.30 | 25 | 47*47*15 | 50 | 36.0 | |

| Φ48 | 1 7/8 | 3 | ±0.30 | 25 | 47*47*15 | 50 | 37.0 | |

| Φ51 | 2=PJ32 | 3 | ±0.35 | 25 | 52*52*20 | 50 | 38.2 | |

| Φ55 | 2 1/5 | 3.5 | ±0.35 | 20 | 52*52*20 | 20 | 20.5 | |

| Φ57 | 2 1/4=PJ36 | 3.5 | ±0.35 | 20 | 52*52*20 | 20 | 21.0 | |

| Φ60 | 2 3/8 | 3.5 | ±0.35 | 20 | 52*52*20 | 20 | 23.5 | |

| Φ64 | 2 1/2=PJ40 | 3.5 | ±0.35 | 20 | 52*52*20 | 20 | 24.0 | |

| Φ65 | 2 3/5 | 3.5 | ±0.35 | 20 | 52*52*20 | 20 | 24.5 | |

| Φ70 | 2 3/4=PJ44 | 3.5 | ±0.40 | 20 | 52*52*20 | 20 | 27.5 | |

| Φ76 | 3=PJ48 | 4 | ±0.40 | 20 | 52*52*20 | 20 | 28.2 | |

| Φ80 | 3 1/5 | 4 | ±0.40 | 20 | 52*52*20 | 20 | 32.5 | |

| Φ83 | 3 1/4=PJ52 | 4 | ±0.40 | 20 | 52*52*20 | 20 | 33.2 | |

| Φ85 | 3 3/8 | 4 | ±0.40 | 20 | 52*52*20 | 20 | 33.8 | |

| Φ89 | 3 1/2=PJ56 | 4 | ±0.50 | 10 | 52*52*20 | 10 | 18.5 | |

| Φ90 | 3 9/16 | 4 | ±0.50 | 10 | 52*52*20 | 10 | 19.0 | |

| Φ95 | 3 3/4=PJ60 | 4 | ±0.50 | 10 | 52*52*20 | 10 | 19.5 | |

| Φ102 | 4=PJ64 | 5 | ±0.50 | 10 | 52*52*20 | 10 | 20.2 | |

| Φ110 | 4 1/3 | 5 | ±0.50 | 10 | 54*54*20 | 10 | 22.0 | |

| Φ114 | 4 1/2=PJ72 | 5 | ±0.50 | 10 | 54*54*20 | 10 | 23.8 | |

| Φ120 | 4 4/5 | 5 | ±0.50 | 10 | 54*54*20 | 10 | 26.8 |

Looking for a stable OEM partner? We provide consistent quality, precision branding, and scalable production for your supply chain.

As a leading manufacturer of hydraulic and industrial hoses, we’re expanding our global network! We invite motivated local partners worldwide to join our exclusive agent program.