In the world of industrial hoses, one material stands out for its exceptional performance and versatility: UHMW (Ultra-High Molecular Weight) hose.

This article delves into the intricacies of what UHMW hose is, its applications across industries, and why it’s revolutionizing fluid transfer systems globally.

What is UHMW Hose?

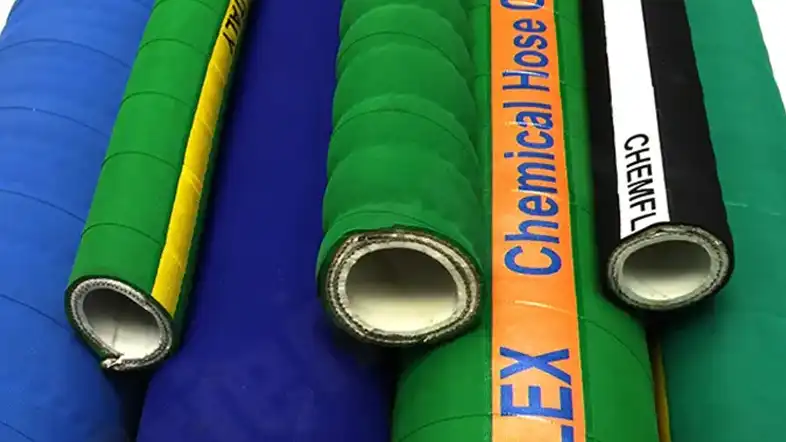

UHMW hose, short for Ultra-High Molecular Weight hose, is a type of hose made from Ultra-High Molecular Weight Polyethylene.

UHMW is indeed a type of chemical hose that offers exceptional performance in handling various chemicals. Its acronym stands for Ultra-High Molecular Weight, referring to the material it’s made from: Ultra-High Molecular Weight Polyethylene (UHMWPE).

This type of hose is specifically designed to withstand the corrosive nature of chemicals, acids, and solvents, making it a reliable choice for industries where the safe transfer of hazardous substances is paramount.

UHMW hoses are widely used in applications such as chemical manufacturing, pharmaceuticals, petrochemicals, and water treatment plants, where the risk of chemical exposure and contamination must be minimized. Their ability to resist degradation from a wide range of chemicals ensures the integrity of the hose and the safety of the materials being transported.

This UHMW hose material is known for its exceptional chemical resistance, flexibility, and durability. It has an extremely high molecular weight, which gives it remarkable strength while remaining lightweight and flexible.

UHMW hose is commonly used in various industries for its ability to withstand corrosive substances, abrasion, and extreme temperatures. It is often utilized in applications where the safe transfer of chemicals, food products, or abrasive materials is necessary.

What is UHMW Hose Made of?

UHMW hose, or Ultra-High Molecular Weight hose, is made from a specialized material called Ultra-High Molecular Weight Polyethylene (UHMWPE).

This material is known for its exceptional strength and durability due to its extremely high molecular weight. UHMWPE is produced through a process called polymerization, where ethylene molecules are polymerized to form long chains with molecular weights that far exceed those of standard polyethylene.

These long chains give UHMWPE its unique properties, including high impact strength, chemical resistance, and low friction coefficient. These characteristics make UHMW hose an ideal choice for applications where durability, flexibility, and resistance to chemicals are essential.

Characteristics of UHMW Hose

The characteristics of UHMW hose are what make it such a valuable asset in numerous industries. Here’s a more detailed explanation:

Chemical Resistance: UHMW hose exhibits unparalleled resistance to a wide range of chemicals, acids, and solvents. This means it can safely transport corrosive substances without the risk of degradation or contamination. Industries such as chemical manufacturing, pharmaceuticals, and petrochemicals rely on UHMW hose for the safe handling of hazardous materials.

Abrasion Resistance: One of the standout features of UHMW hose is its exceptional resistance to abrasion. Even in rugged environments where materials can cause wear and tear on hoses, UHMW hose maintains its integrity, reducing the need for frequent replacements and minimizing downtime.

Flexibility: Despite its robust nature, UHMW hose remains highly flexible. This flexibility allows for easy installation in tight spaces and facilitates smooth fluid transfer operations. It also makes the hose easier to handle and maneuver, enhancing overall efficiency.

Temperature Resistance: UHMW hose is designed to withstand a broad temperature range, from extreme cold to high heat. This versatility ensures reliable performance in diverse operating conditions, making it suitable for use in both indoor and outdoor environments.

Non-Toxicity: UHMW hose is non-toxic and compliant with FDA regulations. This makes it safe for use in applications involving food and beverage transfer, where product purity is essential. The non-toxic nature of UHMW hose also extends its usability to industries with strict health and safety standards.

Applications of UHMW Hose

The versatility of UHMW hose lends itself to a myriad of applications across various industries:

Industrial Chemical Transfer

In industries such as chemical manufacturing, pharmaceuticals, and petrochemicals, where the handling of corrosive chemicals is routine, UHMW hose ensures safe and efficient transfer without the risk of contamination or degradation.

Food and Beverage Processing

Due to its non-toxic nature and FDA compliance, UHMW hose is widely used in food and beverage processing facilities for transferring liquids, syrups, and concentrates without compromising product integrity or safety.

Mining and Material Handling

In mining operations and material handling facilities, where abrasive materials and slurries are prevalent, UHMW hose’s exceptional abrasion resistance prolongs service life and minimizes downtime, thus optimizing operational efficiency.

Agricultural Spraying

In agricultural settings, UHMW hose finds application in pesticide and herbicide spraying equipment, offering resistance to a wide range of chemicals while maintaining flexibility for ease of use.

Water Treatment

UHMW hose plays a crucial role in water treatment plants, facilitating the transfer of chemicals for purification processes while withstanding harsh chemical environments and fluctuating temperatures.

Oil and Gas

In the oil and gas industry, UHMW hose is utilized for transferring petroleum-based products, hydraulic fluids, and drilling muds, providing reliable performance even in demanding offshore environments.

Advantages of UHMW Hose

The adoption of UHMW hose confers numerous advantages:

- Enhanced Safety: Its chemical resistance mitigates the risk of leaks, spills, and accidents, ensuring a safer work environment.

- Cost Savings: Reduced maintenance, downtime, and replacement costs translate to significant savings over the long term.

- Versatility: Its compatibility with a wide range of chemicals and applications makes it a versatile solution for diverse industries.

- Longevity: UHMW hose’s exceptional durability and resistance to abrasion prolong its service life, offering a high return on investment.

FAQs (Frequently Asked Questions)

Can UHMW hose withstand extreme temperatures?

Yes, UHMW hose maintains its integrity across a broad temperature range, from -40°C to 90°C (-40°F to 194°F), ensuring reliable performance in various environments.

Is UHMW hose suitable for use in the food industry?

Absolutely. UHMW hose is non-toxic and FDA-compliant, making it ideal for food and beverage processing applications where product safety is paramount.

What industries commonly use UHMW hose?

UHMW hose finds extensive use in industries such as chemical manufacturing, food processing, mining, agriculture, water treatment, and oil and gas.

How does UHMW hose compare to other hose materials?

UHMW hose surpasses traditional hose materials in terms of chemical resistance, abrasion resistance, flexibility, and longevity, making it the preferred choice for demanding applications.

Can UHMW hose be customized for specific applications?

Yes, UHMW hose can be tailored to meet the unique requirements of different industries, including size, length, and end fittings, ensuring optimal performance and compatibility.

What maintenance is required for UHMW hose?

UHMW hose typically requires minimal maintenance, thanks to its resistance to corrosion and abrasion. Regular inspections for wear and tear are recommended to ensure continued reliability.

Conclusion

In conclusion, UHMW hose represents a pinnacle of innovation in fluid transfer technology, offering unmatched chemical resistance, durability, and versatility across a spectrum of industries. Its adoption translates to enhanced safety, cost savings, and operational efficiency, making it a cornerstone in modern industrial applications.