Steam hoses are essential components in various industrial and commercial settings. They are specifically designed to transport high-pressure steam safely and efficiently. This guide will delve into the intricacies of steam hoses, exploring their construction, types, applications, and crucial considerations for selection and maintenance.

We’ll cover everything from the materials used in their manufacturing to the safety protocols that must be adhered to when handling steam hoses. Whether you’re a seasoned professional or simply curious about this vital piece of industrial equipment, this comprehensive guide will provide you with valuable insights.

What Is a Steam Hose

A steam hose is a specialized type of flexible hose designed to safely and efficiently transport high-temperature steam or hot water. These steam hoses are crucial in various industrial settings where steam is used for processes like cleaning, thawing, and fire prevention.

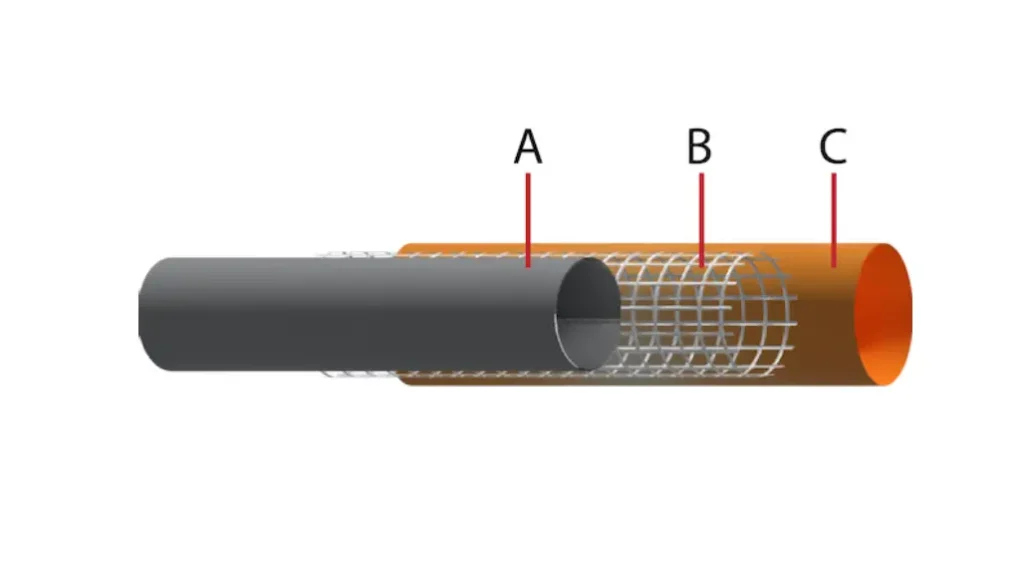

Steam hoses are constructed with specific materials and features to withstand the high pressures and temperatures associated with steam transfer. They typically consist of an inner tube made from heat-resistant materials like EPDM rubber, a reinforcement layer of braided or spiral steel wire for strength, and an outer cover that protects the hose from abrasion, chemicals, and environmental factors.

The choice of materials and construction methods for steam hoses is critical to ensure their reliability and safety. Proper selection and maintenance of steam hoses are essential to prevent accidents and ensure the efficient operation of industrial processes.

What Is a Steam Hose Made of

Steam hoses are typically constructed with several key components:

- Inner Tube: This innermost layer is usually made from EPDM (Ethylene Propylene Diene Monomer) rubber. EPDM is chosen for its exceptional heat resistance, allowing the hose to withstand the high temperatures of steam. It also exhibits good resistance to moisture and steam itself.

- Reinforcement Layer: This layer provides the necessary strength to withstand the high pressures generated by steam. It commonly consists of one or two layers of braided or spiral steel wire. This reinforcement helps prevent the hose from bursting or collapsing under pressure.

- Outer Cover: The outer layer serves as a protective barrier against abrasion, chemicals, and environmental factors. It’s often made from EPDM rubber or chlorobutyl rubber, both of which offer excellent resistance to heat, weather, and chemicals.

What Is Steam Hose Used for

Steam hoses have a wide range of applications in various industries:

- Industrial Cleaning: High-pressure steam is effectively used to clean machinery, equipment, and surfaces in manufacturing plants, food processing facilities, and other industrial settings.

- Thawing: Steam hoses are used to thaw frozen pipes and equipment, particularly during cold weather conditions.

- Fire Prevention: Steam can be used as a fire suppression agent in certain situations.

- Heat Control: Steam hoses can be used to provide heat for various processes, such as heating tanks or thawing materials.

- Construction: Steam hoses are sometimes used in construction applications, such as pile driving.

These are just a few of the many applications where steam hoses play a vital role in industrial operations.

How Does Steam Hose Work

Steam hoses work by safely and efficiently transporting high-temperature steam or hot water from one location to another. Here’s how they function:

- Containment: The primary function is to contain the steam within the hose. The inner tube, typically made of heat-resistant materials like EPDM rubber, forms a barrier to prevent steam leakage.

- Pressure Handling: The reinforcement layer, often composed of braided or spiral steel wire, provides the strength to withstand the high pressures generated by steam. This prevents the hose from bursting or collapsing under pressure.

- Protection: The outer cover protects the hose from abrasion, chemicals, and environmental factors. It also helps to insulate the inner layers, minimizing heat loss.

By combining these elements, steam hoses enable the safe and efficient transfer of steam for various industrial applications.

Conclusion

Steam hoses play a critical role in various industrial applications, ensuring efficient and safe steam transfer. Understanding their construction, types, and applications is crucial for selecting the right hose for your specific needs. By considering factors like temperature, pressure, and chemical compatibility, you can ensure optimal performance and longevity.

Ready to upgrade your steam hose system? Kingdaflex offers a wide range of high-quality wholesale steam hoses designed to meet the demands of diverse industrial applications. Contact us today to discuss your specific requirements and discover the perfect steam hose solution for your business.

Experience the Kingdaflex difference. Our commitment to quality, innovation, and customer satisfaction ensures you receive reliable and durable products that maximize efficiency and minimize downtime.