Durability: Molded rubber hoses are designed to withstand high pressures, extreme temperatures, and harsh chemicals, ensuring long-lasting performance and reduced maintenance.

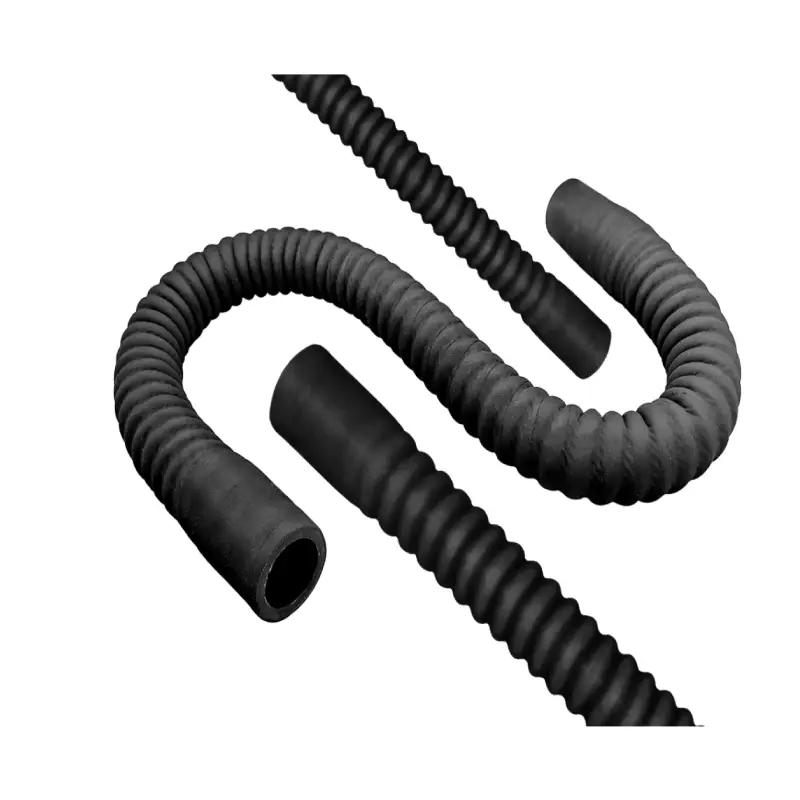

Customizable Shapes: They can be molded into custom shapes, offering flexibility in design to meet specific installation requirements or complex system layouts.

Leak Prevention: The precise molding process ensures tight-fitting connections that help eliminate leaks, promoting efficiency and safety in fluid transfer systems.

High Flexibility: Molded rubber hoses are flexible, making them ideal for tight spaces or dynamic environments where bending and movement are required without compromising flow or structure.

Resistance to Wear: These hoses exhibit excellent abrasion resistance, preventing damage from friction and ensuring a longer lifespan, even in rough operating conditions.