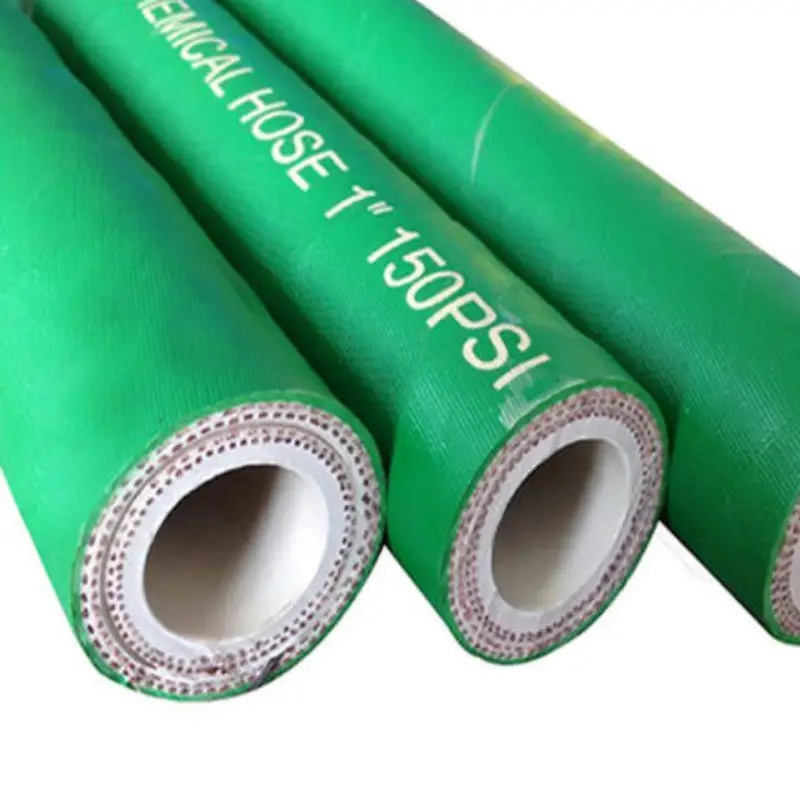

We offer high-performance XLPE hoses featuring a Cross-Linked Polyethylene liner, specifically designed for safely transferring aggressive chemicals. Our hoses provide superior resistance to a vast spectrum of acids and solvents, making them essential for demanding process environments.

Broad Chemical Resistance Our XLPE liner is inert to most industrial acids and alkalis. This allows for versatile use with numerous corrosive chemical solutions.

Non-Contaminating Liner The smooth, non-porous XLPE bore minimizes material retention. This prevents leaching and maintains high purity during transfer operations.

Durable Construction The hoses feature multiple reinforcement plies. This ensures high burst pressure capability and excellent resistance to kinking and external wear.

Temperature Stability We offer XLPE hoses rated for a stable temperature range. They maintain their integrity and chemical resistance under thermal variations in process lines.

We produce hoses with superior Cross-Linked Polyethylene liners for exceptional chemical resistance. Our products are engineered for safe and reliable transfer of aggressive industrial chemicals, acids, and solvents. We guarantee competitive pricing and consistent quality for global supply chain needs.

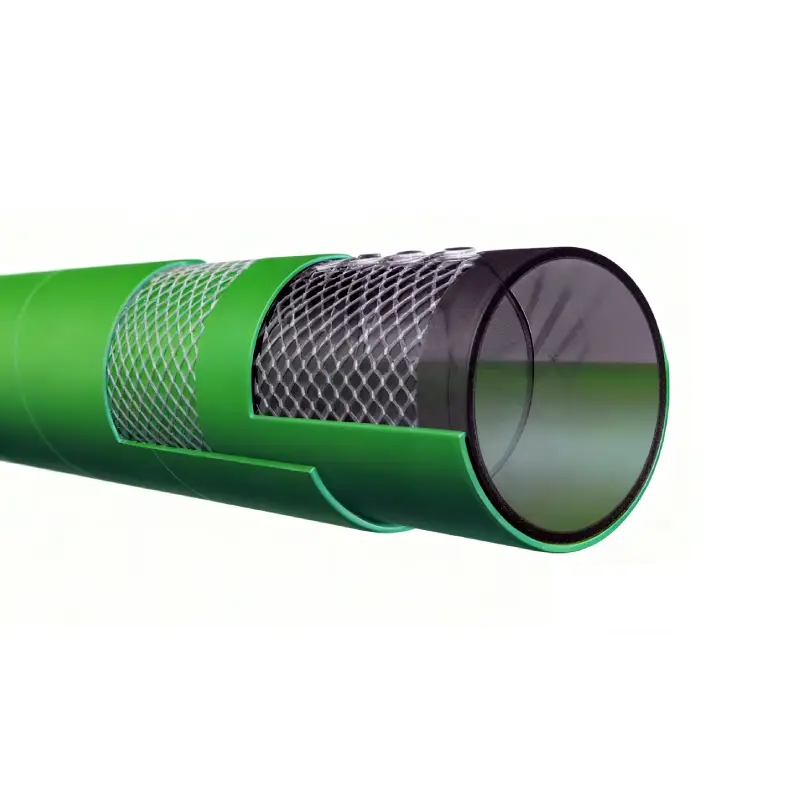

XLPE Liner (Innermost) This core layer is made of cross-linked polyethylene. It provides the smooth, non-porous surface that resists almost all chemicals and ensures non-contaminating media transfer.

Textile Reinforcement Multiple plies of synthetic fabric are helically wound around the liner. This layer provides the necessary structural integrity for the hose to withstand high working pressure without ballooning or bursting.

Helix Wire (Optional/Integral) A steel wire helix is often embedded within the wall. It allows the hose to maintain its round form under full vacuum conditions and provides kink resistance for easier handling.

Outer Cover The exterior is typically a durable, weather-resistant synthetic rubber compound. This protects the internal layers from abrasion, ozone, UV exposure, and external chemical splash damage.

Exceptional Chemical Compatibility The XLPE liner resists a very wide array of corrosive media. This versatility allows the hose to handle strong acids, caustics, and solvents without internal degradation.

Non-Leaching, Smooth Bore The smooth, high-density polyethylene liner is non-porous. This feature minimizes residue build-up, ensuring the highest possible media purity and cleanability.

Excellent Abrasion Resistance XLPE material itself is tough and the hose cover is robust. This combination provides superior external protection against dragging and rough handling on site.

Wide Working Temperature Range Cross-linked polyethylene offers good thermal stability. The hose maintains its structural integrity and chemical inertness across a useful industrial temperature spectrum.

We offer XLPE hoses featuring a Cross-Linked Polyethylene liner, which delivers superior chemical resistance to a broad range of strong acids, alkalis, and solvents. These durable hoses are engineered for industrial safety and integrity, ensuring minimal product contamination and reliable performance in demanding chemical transfer applications.

We offer premium XLPE chemical transfer hoses featuring a cross-linked polyethylene liner that provides exceptional resistance to a wide spectrum of aggressive industrial chemicals, acids, and solvents. These durable, multi-layered hoses ensure minimal product contamination and are engineered for reliable, long-lasting performance in the most demanding process applications.

We offer specialized XLPE delivery and suction hoses, engineered for reliable, versatile transfer of corrosive media. Featuring a Cross-Linked Polyethylene liner, these hoses are resistant to strong acids and solvents, providing the flexibility needed for suction applications and the robust construction required for high-pressure delivery in demanding industrial environments.

We offer specialized XLPE chemical hoses featuring a Cross-Linked Polyethylene liner, which delivers superior chemical resistance to a broad range of strong acids, alkalis, and solvents. These durable hoses are engineered for industrial safety and integrity, ensuring minimal product contamination and reliable performance in demanding chemical transfer applications.

Customizing your XLPE chemical hoses is essential for ensuring they meet the specific chemical resistance, pressure, and temperature demands of your unique application. A tailored hose solution guarantees maximum safety, prevents expensive chemical leaks, and significantly extends the operational service life in harsh environments.

We can customize the thickness of the XLPE inner liner to enhance diffusion resistance when handling highly aggressive, permeating chemicals. We also adjust the specific polyethylene formulation to improve resistance against high temperatures or specific concentrated acids, ensuring long-term barrier integrity.

We allow specification of the reinforcement layers, choosing between high-strength textile braids or helical steel wire for full vacuum service. We engineer the layering to precisely meet your required working and burst pressure ratings, guaranteeing safety and structural stability during high-volume or pulsed transfer operations.

We can customize the outer cover with specialized compounds designed to resist severe external conditions, such as continuous dragging, ozone exposure, or UV degradation. This enhances the durability of the hose assembly, protecting the critical internal reinforcement from environmental or mechanical damage on the plant floor.

We provide custom crimping services using end fittings made from compatible materials like stainless steel or specialized alloys. We ensure the fittings are permanently attached and chemically resistant, offering a non-leaking, secure connection that eliminates the most common failure point in chemical transfer assemblies.

XLPE stands for Cross-Linked Polyethylene, a thermoset plastic material that is created by chemically linking the polymer chains of standard polyethylene. This cross-linking process changes the material’s properties, making it superior to standard polyethylene by increasing its strength, chemical resistance, and thermal stability. It is often used as a liner in industrial hoses and for insulation in electrical cables.

In the industry of industrial hoses, the XLPE liner is highly valued for its near-universal chemical inertness. This means it is highly resistant to degradation from a vast range of aggressive media, including strong acids, caustics, and many industrial solvents, which makes the hose safer and gives it a significantly longer service life in demanding chemical transfer applications.

An XLPE hose (Cross-Linked Polyethylene) is used primarily for the safe and reliable transfer of aggressive, corrosive, and concentrated industrial chemicals. Its core function is to provide a non-reactive barrier against media like strong inorganic acids, caustics, and specific solvents, ensuring both fluid integrity and maximum operational safety in processing environments.

The unique chemical inertness of the XLPE liner allows this hose to serve a wide array of demanding applications where standard rubber or PVC hoses would quickly degrade. It is the go-to flexible solution for industries requiring versatility and high resistance to chemical attack under varying temperature and pressure conditions.

Bulk Chemical Transfer XLPE hoses are widely used to safely load and unload strong chemicals from storage tanks, railcars, and tanker trucks. They handle concentrated acids (e.g., 98% Sulfuric Acid) and caustics, resisting corrosion and ensuring efficient, large-volume transfers at terminals and production sites.

Process Line Integration They serve as flexible connections within chemical manufacturing and processing plants, moving reactants between blending vessels, heat exchangers, and filtration units. The hose maintains purity and resists high temperatures associated with exothermic chemical reactions, offering crucial flexibility in a fixed piping system.

Corrosive Cleaning Solutions The hoses are essential for conveying aggressive cleaning agents and sanitizers, such as hot strong acids and powerful alkaline solutions used for sterilizing industrial equipment and tanks. Their chemical resistance allows for repeated use without degradation from continuous exposure to these harsh cleaners.

General Plant Maintenance XLPE hoses are used for general utility tasks around a chemical facility, including transferring wastewater that may contain trace amounts of various corrosive materials. This ensures that routine maintenance operations can be performed safely without concern for hose failure from residual chemical content.

Choosing Kingdaflex XLPE hoses guarantees superior chemical resistance and outstanding durability for your most challenging fluid transfer applications. Our use of premium Cross-Linked Polyethylene liners ensures compatibility with a vast spectrum of aggressive acids, solvents, and caustics, minimizing the risk of failure and protecting personnel.

We commit to engineering hoses that exceed industry safety and performance standards. By combining our specialized XLPE material science with robust reinforcement, Kingdaflex delivers a cost-effective, long-lasting solution that drastically reduces downtime and maintenance costs in your critical chemical processes.

Supreme Chemical Inertness Our XLPE liner offers near-universal resistance to corrosive media, including highly concentrated acids and alkalis. This key feature guarantees that the hose structure remains stable and prevents contamination of the transferred chemical, ensuring product quality and safety.

Robust and Reliable Construction Kingdaflex builds its XLPE hoses with multiple layers of high-tensile fabric and steel wire helix. This ensures exceptional pressure capacity and full vacuum resistance, allowing the hose to maintain integrity under various fluid dynamics and prevent kinking during heavy use.

Excellent Temperature Stability Our specific XLPE formulation is designed to perform reliably across a broad operational temperature range. This stability means the hose resists stiffening in cold environments and softening in hot processes, providing consistent flexibility and safe performance year-round.

Custom End Fitting Security We offer specialized crimping with chemically compatible end fittings, such as stainless steel, matched to your requirements. This eliminates the most common point of failure—the connection—ensuring a leak-proof, permanently secured assembly that maximizes safety and process continuity.