![]()

Today we are aiming to share the importance of reinforcement in hydraulic hoses. It is really critical to select the right reinforced hydraulic hose for your hydraulic hose project, to meet the specific requirements of hydraulic hose application.

The reinforcement is the most important factor you must consider seriously for the hydraulic hose selection.

What Is Hydraulic Hose Reinforcement

Hydraulic hose reinforcement refers to the layers of materials added to the inner tube of a hydraulic hose to enhance its strength, flexibility, and resistance to various environmental factors. These reinforcing layers are crucial in preventing the hose from bursting under high pressure and protecting it from abrasion, chemicals, and temperature extremes.

Reinforced hydraulic hoses are essential for:

- Safety: Preventing catastrophic failures that could lead to injuries or property damage.

- Reliability: Ensuring consistent and reliable performance of hydraulic systems.

- Longevity: Extending the lifespan of hydraulic hoses, reducing maintenance costs and downtime.

- Efficiency: Optimizing the performance of hydraulic equipment by preventing leaks and maintaining pressure.

Hydraulic Hose Reinforcement Types: Spiral and Braided

First things first, you need to identify what type of hydraulic hose you are looking for, here are two main types of hydraulic hose, including spiral hydraulic hose and braided hydraulic hose.

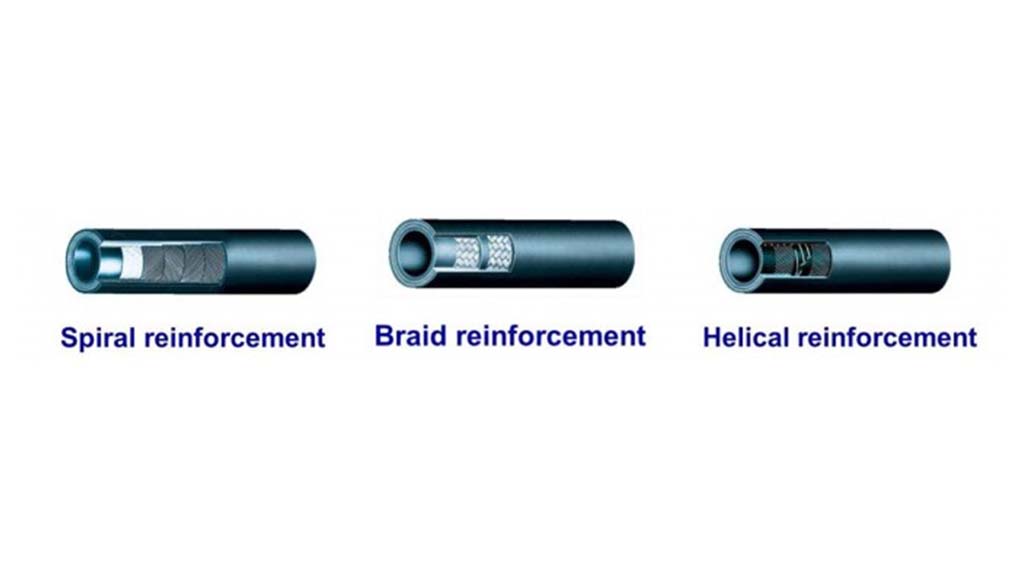

In the hydraulic hose industry, you can see three types of hydraulic hose normally.

Understanding the various types of hydraulic hose reinforcement is crucial for selecting the right one for your application. Let’s explore the options available:

Wire Braid Reinforcement

Wire braid reinforcement consists of a series of wire strands wound around the hose. It provides excellent flexibility and resistance to high pressures, making it suitable for many applications.

Spiral Wire Reinforcement

Spiral wire reinforcement involves helically wrapping multiple wires around the hose. This design offers increased strength and is ideal for applications with extreme pressures and heavy loads.

Textile Reinforcement

Textile reinforcement uses multiple layers of textile materials, such as cotton or synthetic fibers. It’s a cost-effective option for low to medium-pressure hydraulic systems.

Steel Wire Reinforcement

Steel wire reinforcement provides exceptional strength and durability. It’s commonly used in high-pressure applications and environments with high mechanical stress.

These two types of hydraulic hose differ in their reinforcement.

- Spiral Hydraulic Hose: Spiral reinforcement ( Spiral hydraulic hose is also called coiled hydraulic hose because the reinforcement layer is coiled throughout the hydraulic hose inner tube with the method like the electric wire coiled on the reel.

- Braided Hydraulic Hose: Braided reinforcement

The Importance of Hydraulic Hose Reinforcement

The reinforcement layer of the hydraulic hose is a critically important hydraulic hose because the reinforcement can determine the hydraulic hose strength, to pin the hydraulic hose’s working pressure.

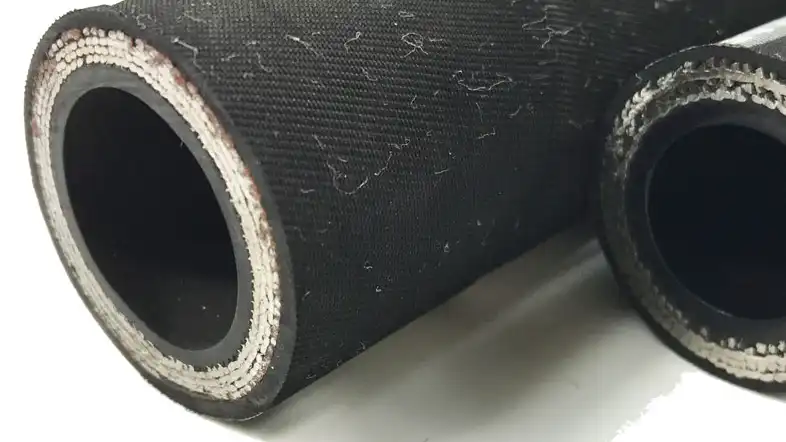

How many layers of reinforcement are manufactured in the hydraulic hose production can determine how strong the hydraulic hose is, here at our hydraulic hose manufacturer, we are trying our best to utilize premium stainless steel wires and synthetic rubber material to create the best reinforcement to ensure the hydraulic hose strength and working pressure.

The quality of the hydraulic hose reinforcement can ensure the hydraulic-based project goes with the safety and the shoddy hydraulic hose will cause many potential safety damages, such as hydraulic hose leaking, bursting, and even death.

From the selection of raw materials to make hydraulic hose reinforcement, we are aiming to manufacture the best hydraulic hose for your hydraulic project.

Purpose of Hydraulic Hose Reinforcement Layer

The hydraulic hose reinforcement layer is the first component you need to consider when selecting a proper hydraulic hose for your hydraulic project. Because the reinforcement is the core of a hydraulic hose, which can determine how much strength a hydraulic hose will get.

You can consult an experienced hydraulic hose expert to get some suggestions about hydraulic hose reinforcement, and you need to choose the right hydraulic hose based on its application.

What Type of Reinforcement is Used in Hydraulic Hoses?

Hydraulic hoses typically use steel wire reinforcement to provide strength and durability. This steel wire reinforcement helps the hoses withstand high-pressure applications and prevent them from bursting or leaking.

The number of layers and the type of steel wire reinforcement can vary depending on the specific requirements of the hydraulic system and the pressure it needs to handle.

Common types of hydraulic hose reinforcement include single-wire braid, double-wire braid, four-wire braid, and spiral-wire reinforcement, each offering different levels of strength and flexibility to suit various hydraulic applications.

Reinforced Hydraulic Hose

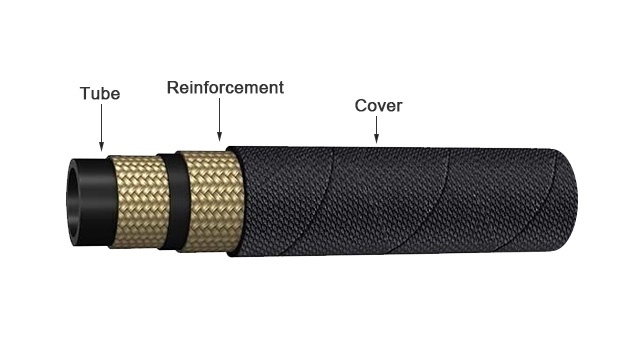

Reinforced hydraulic hose is a specialized type of hose designed to withstand high pressures and harsh environments, typically used in hydraulic systems. It’s constructed with a multi-layer design, incorporating various materials to provide strength, flexibility, and resistance to specific conditions.

Components of Reinforced Hydraulic Hose:

- Inner Tube: The core of the hose, usually made of synthetic rubber or thermoplastic elastomer (TPE), providing flexibility and resistance to hydraulic fluids.

- Reinforcement Layers: Multiple layers of reinforcing materials, such as steel wire, synthetic fiber braid, or textile fabric, are added to the inner tube to provide strength and support.

- Outer Cover: An outer layer, typically made of synthetic rubber or thermoplastic, protects the reinforcement layers from abrasion, chemicals, and environmental factors.

Types of Reinforcement:

- Wire Braid: Offers excellent strength and burst resistance but can be less flexible.

- Textile Braid: Provides good flexibility and abrasion resistance, often used in applications requiring frequent bending.

- Spiral Wire: A combination of wire braid and textile braid, offering a balance of strength and flexibility.

Applications of Reinforced Hydraulic Hose:

- Heavy Machinery: Construction equipment, cranes, excavators, and bulldozers.

- Industrial Processes: Manufacturing, mining, and oil and gas operations.

- Agricultural Equipment: Tractors, combines, and balers.

- Mobile Hydraulic Systems: Forklifts, dump trucks, and mobile cranes.

Factors to Consider When Choosing Reinforced Hydraulic Hose:

- Pressure Rating: Ensure the hose can handle the maximum operating pressure of your system.

- Temperature Range: Select a hose that can withstand the temperature extremes of your environment.

- Fluid Compatibility: Choose a hose compatible with the specific hydraulic fluid being used.

- Abrasion Resistance: If the hose will be exposed to abrasive conditions, select a hose with a durable outer cover.

- Bend Radius: Consider the minimum bend radius required for your application.

By understanding the components, types, and applications of reinforced hydraulic hose, you can make informed decisions when selecting the right hose for your specific needs.

Would you like to know more about specific types of reinforced hydraulic hose or have any other questions?

Conclusion

Hydraulic hose reinforcement is crucial for ensuring the safety, reliability, and longevity of hydraulic systems. The reinforcing layers provide essential support, preventing the hose from bursting under high pressure and protecting it from external factors such as abrasion, chemicals, and temperature extremes.

Get Premium Reinforced Hydraulic Hose from Us

Our company specializes in providing high-quality, reinforced hydraulic hose designed to meet the demanding requirements of various industries. Our products are engineered with advanced materials and manufacturing techniques to ensure exceptional performance, durability, and safety.

When you choose our reinforced hydraulic hose, you can expect:

- Superior quality: We source only the finest materials and employ rigorous quality control measures.

- Wide range of options: We offer a variety of hose types and sizes to suit your specific needs.

- Expert advice: Our knowledgeable team can provide guidance on selecting the right hose for your application.

- Competitive pricing: We offer competitive pricing without compromising on quality.

By investing in premium reinforced hydraulic hose from our company, you’re making a wise choice that will benefit your business in the long run.

Contact us today to learn more about our products and services.