Understanding the temperature limits of a rubber hose is essential for safe and efficient operation in industrial, automotive, and hydraulic applications. Using a hose beyond its heat tolerance can lead to leaks, cracks, or system failures, impacting both performance and safety. Choosing the right material ensures reliable, long-lasting service.

Different types of rubber hoses offer varying levels of heat resistance, depending on their construction and materials. High-temperature hoses can handle extreme conditions, while standard hoses are suitable for moderate temperatures. Knowing these limits helps you select the proper hose for your specific application, preventing costly damage and downtime.

Rubber Hose Temperature Rating

Rubber hose temperature ratings indicate the safe range of temperatures in which a hose can operate without damage or performance loss. Understanding these ratings is crucial for industrial, automotive, and hydraulic applications to prevent leaks, hose failure, and ensure long-lasting, reliable operation under varying heat conditions.

- Standard Rubber Hose Ratings – Typically rated from -40°C to 80°C. These hoses are suitable for general applications, offering flexibility and durability in moderate conditions. Exceeding these limits can cause cracking, leaks, and reduced service life.

- High Temperature Rubber Hose Ratings – Can withstand temperatures up to 200°C or higher. Constructed with heat-resistant synthetic rubber and reinforced layers, these hoses maintain integrity, prevent deformation, and ensure safe fluid or gas transfer under extreme heat conditions.

- Silicone Rubber Hose Ratings – Often rated from -60°C to 250°C. Silicone hoses provide exceptional flexibility, chemical resistance, and heat endurance, making them ideal for automotive engines, industrial processes, and high-temperature fluid transfer applications.

- Reinforced Rubber Hose Ratings – Incorporating textile or metal wire reinforcement, these hoses achieve higher temperature tolerance and pressure resistance. They prevent bursting, maintain structural integrity, and are suitable for hydraulic, chemical, or high-heat applications.

Rubber Hose Temperature Ratings Chart

| Hose Type | Minimum Temperature | Maximum Temperature | Typical Applications |

|---|---|---|---|

| Standard Rubber Hose | -40°C | 80°C | General industrial, low-heat fluid transfer |

| High Temperature Rubber Hose | -40°C | 200°C+ | Automotive, industrial, hydraulic systems |

| Silicone Rubber Hose | -60°C | 250°C | Engine compartments, high-heat applications |

| Reinforced Rubber Hose | -40°C | 220°C | High-pressure, chemical, and hydraulic applications |

How Much Temperature Can a Rubber Hose Withstand?

Rubber hoses are designed to operate within specific temperature ranges depending on their material composition and construction. Understanding these limits is crucial to ensure safe fluid or gas transfer, prevent damage, and maintain reliable performance in industrial, automotive, and hydraulic applications.

- Standard Rubber Hoses – Typically withstand temperatures from -40°C to 80°C. These hoses are suitable for general applications, offering flexibility and durability in moderate heat conditions, but may degrade if exposed to continuous high temperatures or hot fluids.

- High Temperature Rubber Hoses – Can handle temperatures up to 200°C or higher. Constructed with heat-resistant synthetic rubber and reinforced layers, these hoses maintain structural integrity, resist cracking, and ensure reliable fluid transfer in extreme heat environments.

- Silicone Rubber Hoses – Often tolerate temperatures ranging from -60°C to 250°C. Silicone provides excellent flexibility, chemical resistance, and long-term durability, making it ideal for automotive engines, industrial processes, and high-heat applications.

- Specialized Hoses with Reinforcements – Some hoses include textile or metal wire reinforcements, enhancing their heat tolerance and pressure resistance. These designs allow safe operation under higher temperatures and prevent deformation or bursting during extreme use.

- Protective Measures – Temperature resistance can be enhanced with additional covers, coatings, or insulation. These protective features shield hoses from external heat sources, UV exposure, and abrasion, ensuring long-lasting performance even in harsh environments.

How to Determine the Temperature Rating of a Rubber Hose?

Determining the temperature rating of a rubber hose is essential for safe and efficient operation in industrial, automotive, and hydraulic systems. Knowing a hose’s heat tolerance prevents leaks, cracks, and failures, ensuring long-lasting performance. Temperature ratings depend on hose material, reinforcement, and intended application, making proper selection critical.

- Check Manufacturer Specifications – Always refer to the hose manufacturer’s datasheet or catalog. These documents provide the minimum and maximum temperature limits, material composition, and recommended applications, ensuring safe use and preventing damage from exceeding thermal limits.

- Identify Hose Material – The type of rubber or synthetic compound affects heat resistance. Materials like silicone, EPDM, or nitrile have different temperature tolerances, so understanding the composition helps accurately determine the hose’s safe operating range.

- Consider Reinforcements – Hoses with textile or metal wire reinforcements can withstand higher temperatures and pressures. Inspecting reinforcement layers provides insight into the hose’s structural integrity under heat, preventing deformation, bursting, or premature failure.

- Assess Operating Environment – Evaluate external conditions such as ambient temperature, exposure to hot surfaces, and fluid temperature. These factors influence the effective temperature rating and help select a hose that will perform reliably in real-world conditions.

- Look for Protective Features – Some hoses include heat-resistant covers, coatings, or insulation. These features increase temperature tolerance, extend hose life, and ensure consistent performance in high-heat industrial, automotive, or hydraulic applications.

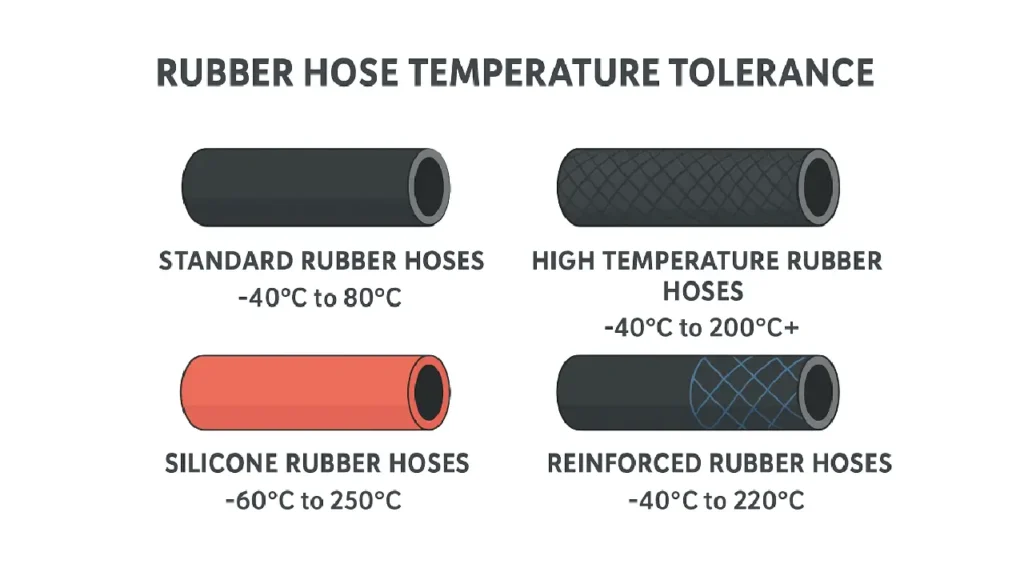

Rubber Hose Temperature Tolerance

Rubber hose temperature tolerance defines the range of temperatures a hose can safely handle without damage or reduced performance. Understanding tolerance is vital for industrial, automotive, and hydraulic applications, ensuring hoses operate reliably, resist aging, and maintain flexibility under both high and low-temperature conditions.

- Standard Rubber Hoses – Typically tolerate temperatures between -40°C and 80°C. These hoses are suitable for general applications, providing flexibility and durability under moderate conditions, but exceeding limits can cause cracks, leaks, and shortened service life.

- High Temperature Rubber Hoses – Designed to handle temperatures up to 200°C or more. Constructed with heat-resistant synthetic rubber and reinforced layers, they maintain structural integrity, resist deformation, and ensure reliable fluid or gas transfer under extreme heat.

- Silicone Rubber Hoses – Can withstand a wide temperature range from -60°C to 250°C. Silicone offers excellent flexibility, chemical resistance, and durability, making it ideal for engines, industrial processes, and high-temperature fluid transfer systems.

- Reinforced Rubber Hoses – Featuring textile or metal wire reinforcements, these hoses achieve enhanced temperature tolerance and pressure resistance. Reinforcements prevent bursting or collapse, ensuring safe operation in hydraulic, chemical, or high-heat applications.

- Protective Covers and Coatings – Adding abrasion-resistant, heat-resistant, or UV-protective covers increases hose temperature tolerance. These protective features extend service life and ensure consistent performance in harsh or high-heat environments.

Conclusion

Selecting a rubber hose that can withstand the appropriate temperature is critical for system safety and efficiency. At Kingdaflex, we provide a wide range of high-quality rubber hoses designed for high-temperature, industrial, and automotive applications. Our products ensure durability, flexibility, and reliable performance in even the most demanding conditions.

By understanding the temperature tolerance of different rubber hoses, you can prevent leaks, bursts, and other operational failures. Kingdaflex hoses are engineered with heat-resistant synthetic rubber, reinforcement layers, and protective covers, offering exceptional longevity and stability. Whether for hydraulic, chemical, or automotive systems, our hoses deliver optimal performance.

For businesses or individuals seeking bulk solutions, Kingdaflex offers wholesale rubber hoses with customizable specifications. From size and material to pressure and temperature ratings, we provide tailored hoses to meet your exact requirements. Trust Kingdaflex for reliable, long-lasting, and high-performance rubber hoses in any high-temperature application.