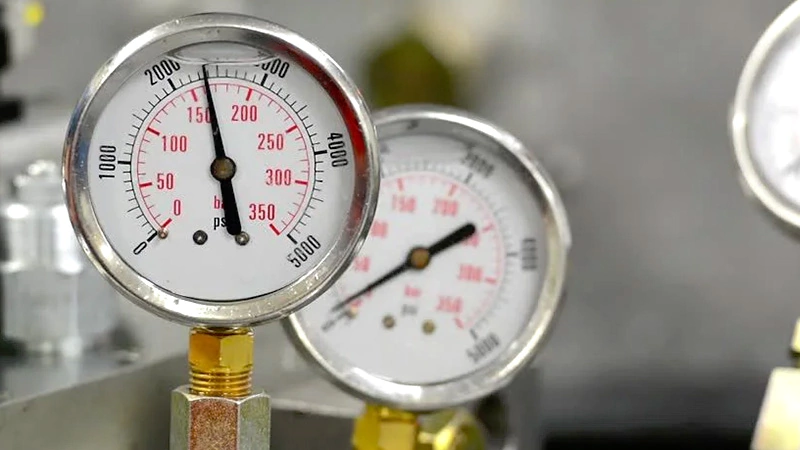

When replacing a hydraulic line, many buyers make a critical mistake: they focus solely on the size—1/2 inch—while overlooking the specific pressure rating. In modern high-performance machinery, where system pressures are constantly increasing, this oversight can be both dangerous and expensive.

The honest answer is: It depends entirely on the specific standard. While a standard single-wire (R1) hose will fail instantly, a double-wire SAE 100R2AT is often rated exactly at 4000 PSI—placing it right on the “red line” of its performance limit.

In this guide, Kingdaflex experts will break down the critical relationship between Maximum Working Pressure and Burst Pressure. We will explain why operating at the limit is risky and how understanding the 4:1 Safety Factor can save you from catastrophic blowouts and costly equipment downtime.

Understanding the Numbers: Working Pressure vs. Burst Pressure

Before selecting a hose for your 4000 PSI system, you must distinguish between two critical metrics found on every spec sheet: Maximum Working Pressure and Minimum Burst Pressure. Confusing these two is a leading cause of preventable hydraulic accidents.

Maximum Working Pressure (WP) This is the “safe zone.” It represents the maximum pressure the hose is designed to handle on a continuous basis during operation. For a 1/2 high pressure hydraulic hose, the manufacturer guarantees performance and longevity only as long as the system pressure remains below this limit.

Minimum Burst Pressure This is the ultimate failure point—the pressure level at which the hose wall will physically rupture or the fitting will blow off.

The 4:1 Safety Factor Rule Global industry standards (such as SAE J517 and DIN EN) dictate a strict 4:1 safety factor for hydraulic hoses. This means if a hose is rated for a working pressure of 4000 PSI, it must be engineered to withstand a burst pressure of at least 16,000 PSI.

Why does this gap exist? You might be tempted to think, “If it bursts at 16,000 PSI, surely I can run it at 5000 PSI?” Absolutely not.

The safety margin is not “extra capacity” for you to use. It is insurance designed to absorb:

- Sudden pressure spikes (surges) caused by valves slamming shut.

- Mechanical vibration and physical flexing during movement.

- Natural degradation of the rubber materials over time.

Operating a hose above its rated Working Pressure—even if it remains far below the Burst Pressure—eats into this safety margin, leading to catastrophic failure.

Evaluating “Standard” 1/2 Inch Hoses: R1 vs. R2

To the untrained eye, most hydraulic hoses look identical: black, rubber, and marked with “1/2 Inch.” However, beneath the cover, the difference in wire reinforcement creates a massive gap in pressure capability.

When sizing for a 4000 PSI application, you will typically encounter two industry-standard options. Here is how they stack up against your requirements.

SAE 100R1AT (1-Wire Braided) – The “Danger Zone”

This is the most common entry-level hydraulic hose. It features a single layer of high-tensile steel wire braid reinforcement.

- The Specs: A standard 1/2 inch SAE 100R1AT hose typically has a Maximum Working Pressure of only 2,320 PSI (160 Bar).

- The Verdict: Absolutely Unsafe. Using an R1 hose on a 4000 PSI system is not just a risk; it is a guaranteed failure. The system pressure exceeds the hose’s rating by over 70%, pushing it dangerously close to its burst point immediately upon startup. Never use a 1-wire hose for high-pressure excavation or mining equipment.

SAE 100R2AT (2-Wire Braided) – The “Borderline” Case

This is the industry workhorse and the most frequently misused hose in high-pressure scenarios. It features two layers of steel wire braid.

- The Specs: A high-quality 2SN SAE 100R2AT 1/2″ hose —like those manufactured by Kingdaflex—is typically rated for a Maximum Working Pressure of 4,000 PSI (275 Bar).

- The Verdict: Technically Compatible, But Risky. On paper, the numbers match: a 4000 PSI hose for a 4000 PSI system. However, in engineering terms, this is known as “running at redline.”

The “Borderline” Issue While our SAE 100R2AT is fully compliant with international standards, operating a hose at 100% of its rated capacity continuously leaves zero room for error.

- If your machine’s relief valve is set to 4000 PSI, the hose is under maximum stress 100% of the time.

- The heat generation and wire fatigue accelerate dramatically compared to running at 50% or 70% capacity.

For intermittent use (like a log splitter), R2 is acceptable. But for continuous-duty machinery (like a hydrostatic drive), relying on a “borderline” R2 hose often leads to premature failures and frequent replacement intervals.

The Hidden Killer: Pressure Spikes and Impulse Loads

If your system’s gauge reads “4000 PSI,” does that mean your pressure never exceeds that number? Almost certainly not. This common misconception is the “hidden killer” of hydraulic assemblies.

The Reality of Dynamic Systems Hydraulic systems are rarely static. They are dynamic environments subject to rapid changes in flow and load. When a heavy excavator bucket hits a rock, or a solenoid valve slams shut instantly, the fluid momentum creates a shockwave known as a pressure spike or surge.

These spikes can last mere milliseconds—too fast for a standard analog gauge to register—but they can momentarily drive internal pressure up to 5000 PSI or even 6000 PSI in a system rated for 4000 PSI.

Metal Fatigue and Hose Failure While a quality 1/2 inch hydraulic hose has a 4:1 safety factor to prevent immediate bursting during a spike, the damage is cumulative. Think of it like bending a paperclip back and forth.

- Every time the pressure spikes above the hose’s rated working pressure, the high-tensile steel wire reinforcement expands and contracts aggressively.

- Over time, this causes metal fatigue in the wire braid.

- Eventually, the wire snaps, leading to a “pinhole” leak or a catastrophic blowout, often long before the hose’s theoretical lifespan is up.

The Importance of Impulse Testing At Kingdaflex, we simulate these conditions using Impulse Testing. A standard SAE 100R2AT hose is designed to withstand 200,000 impulse cycles at 133% of its working pressure. However, if your application involves high-frequency hammering (like hydraulic breakers) or constant heavy lifting at the hose’s limit, you will burn through those cycles rapidly.

The Verdict: If your equipment operates consistently at 4000 PSI with frequent surges, using a hose rated exactly at 4000 PSI is running the system at “redline.” For reliability, you need a hose with a higher pressure ceiling to absorb those spikes safely.

The Professional Solution: Upgrading to Spiral Hoses (4SP/4SH)

| Hose Standard | Hose ID (mm) | Hose OD (Max mm) | Working Pressure (Bar / PSI) | Burst Pressure (Bar / PSI) | Min Bend Radius (mm) |

| SAE 100 R1AT / 1SN | 12.7 | 21.4 | 160 / 2320 | 640 / 9280 | 180 |

| SAE 100 R2AT / 2SN | 12.7 | 23.0 | 275 / 3990 | 1100 / 15950 | 180 |

| SAE 100 R16 | 12.7 | 22.0 | 275 / 3990 | 1100 / 15950 | 90 |

| SAE 100 R17 | 12.7 | 21.1 | 210 / 3045 | 840 / 12180 | 90 |

| EN 856 4SP | 12.7 | 25.4 | 415 / 6020 | 1660 / 24070 | 230 |

| SAE 100 R12 | 12.7 | 24.6 | 280 / 4060 | 1120 / 16240 | 180 |

| SAE 100 R15 | 12.7 | 26.8 | 420 / 6090 | 1680 / 24360 | 200 |

| SAE 100 R3 (Textile) | 12.7 | 24.6 | 70 / 1015 | 280 / 4060 | 125 |

| SAE 100 R6 (Textile) | 12.7 | 19.7 | 28 / 406 | 112 / 1624 | 100 |

When your application demands continuous performance at 4000 PSI, relying on a hose that is merely “rated” for 4000 PSI is a gamble. The professional engineering strategy is to “over-spec” your components—choosing a hose with a pressure rating significantly higher than your system’s peak demand.

For 1/2 inch applications, this means graduating from “Wire Braided” to “Wire Spiral“ technology.

The Power of DIN EN856 4SP / 4SH While standard R1 and R2 hoses use a woven wire braid, our DIN EN856 4SP (4-Wire Spiral) hoses are constructed with four layers of high-tensile steel wire wrapped in alternating directions.

- No Crossover Points: In braided hoses, wires cross over each other, creating friction points that can wear down under high impulse. Spiral wires run parallel, eliminating this internal friction.

- The Pressure Jump: For a 1/2 inch size, upgrading to a Kingdaflex 4SP hose boosts your Maximum Working Pressure from the borderline 4000 PSI up to a massive 6000 PSI (420 Bar).

Why Over-Spec? By installing a 6000 PSI rated hose on a 4000 PSI machine, your system operates at only 66% of the hose’s capacity. This creates a huge buffer zone. The hose can easily absorb violent pressure spikes and vibrations without ever approaching its fatigue limit. The result is a service life that is often 3 to 5 times longer than a standard R2 hose in the same application.

A Note on Compact Options (R16/R17) If installation space is tight and you cannot accommodate the thicker wall of a spiral hose, consider our high-performance SAE 100R16 or R17 series. These “Compact” hoses maintain high-pressure ratings (often matching R2AT) but with a significantly smaller bend radius. However, for pure pressure safety in heavy-duty mining or excavation, the 4-Wire Spiral remains the gold standard.

How to Choose the Right Hose from Kingdaflex

Making the right choice comes down to understanding your specific application dynamics, not just the gauge reading.

- For Static/Steady Applications: If your equipment operates at steady pressure with minimal spikes (such as hydraulic lifts or jacks), our premium SAE 100R2AT 1/2″ hose provides a reliable and cost-effective solution that meets the 4000 PSI standard.

- For Dynamic/Heavy-Duty Applications: For excavators, hydrostatic drives, or machinery with hammer attachments, the DIN EN856 4SP series is the only safe investment.

Don’t forget the connections. High-pressure applications require matched fittings. Kingdaflex offers complete custom assemblies with specialized Interlock fittings designed to grip spiral hoses securely, ensuring the coupling holds tight even under extreme pressure surges.

Conclusion

Never gamble with hydraulic safety. While a standard 1/2 inch hose might physically fit your machine, ensuring it can handle your system’s peak pressure spikes is the difference between a productive day and a hazardous blowout. When in doubt, always choose the higher safety margin.

Ready to upgrade your inventory? Contact Kingdaflex’s technical team today. Whether you need bulk R2AT or high-performance 4SP hoses, we provide factory-direct wholesale pricing and expert guidance to keep your equipment running safely.