Teflon and PTFE (Polytetrafluoroethylene) are two terms commonly used in the world of materials and manufacturing. Both are associated with nonstick properties and high resistance to heat and chemicals. However, there are important distinctions between the two that are worth exploring.

We will delve into the world of Teflon vs PTFE, comparing their characteristics, and applications, and highlighting the key differences.

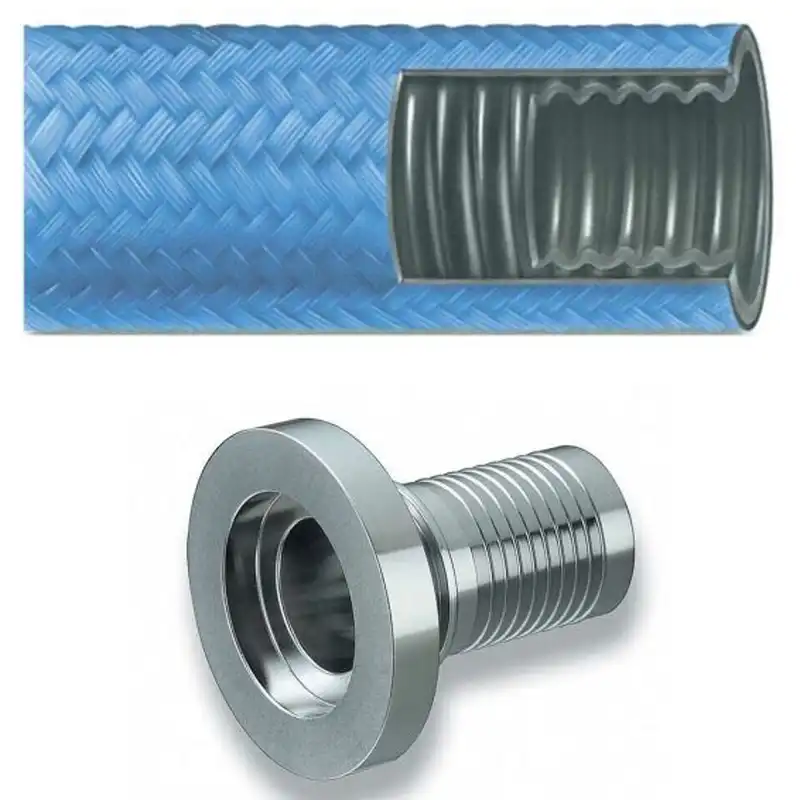

What is Teflon Hose

Teflon hose refers to flexible tubing made from polytetrafluoroethylene (PTFE), commonly known as Teflon.

Key Characteristics:

Low Friction: The smooth surface of PTFE minimizes friction, reducing pressure drop and improving fluid flow efficiency.

Chemical Resistance: PTFE is highly resistant to a wide range of chemicals, including acids, bases, solvents, and fuels.

Temperature Resistance: Teflon hoses can withstand a wide temperature range, from extremely low temperatures to high temperatures.

Non-Stick Properties: The non-stick nature of PTFE prevents material buildup inside the hose, ensuring smooth fluid flow.

Flexibility: Teflon hoses are flexible and can be easily routed and installed in various applications.

What is PTFE Hose

PTFE, on the other hand, is the abbreviation for Polytetrafluoroethylene, which is a synthetic fluoropolymer of tetrafluoroethylene. It is the primary component of Teflon and is known for its remarkable nonstick properties and high resistance to heat and chemicals.

PTFE Properties

You’ve accurately summarized the key properties of PTFE (Polytetrafluoroethylene):

- Low Friction: PTFE boasts one of the lowest coefficients of friction among known solids, making it incredibly slippery and resistant to wear and tear.

- Hydrophobic: PTFE repels water and other water-based substances exceptionally well.

- Chemical Inertness: Highly resistant to most chemicals, acids, bases, and solvents.

- Temperature Resistance: Withstands a broad temperature range, from extremely cold to very high temperatures without significant degradation.

- High Flexural Strength: Retains strength and flexibility even at low temperatures.

- Excellent Electrical Insulation: Exhibits high electrical resistance and dielectric strength, particularly at high frequencies.

These unique properties make PTFE a highly versatile material with applications in diverse fields, including non-stick cookware, aerospace, electronics, and chemical processing.7

PTFE Applications

Here are some trending applications of PTFE materials that you can know.

1. Electrical and Electronics:

- Wiring: PTFE’s excellent dielectric properties (high electrical resistance and low dielectric constant) make it ideal for wiring in aerospace and computer applications.

- Hook-up Wires: Used in applications where high-temperature stability and electrical insulation are crucial.

- Coaxial Cables: Its low-loss properties make it suitable for high-frequency applications.

- Replacement for Polyethylene: PTFE offers a significant upgrade over polyethylene in electrical applications due to its superior temperature resistance and overall performance.

2. Mechanical Applications:

- Bearings: PTFE’s low friction makes it an excellent choice for plain bearings, gears, and slide plates.

- Wear Reduction: PTFE components reduce friction and wear, leading to:

- Longer-lasting parts

- Improved machine performance

- Reduced energy consumption

- Lower maintenance costs

- Increased equipment lifespan

3. Chemical Processing:

- Chemical Containment: PTFE’s high temperature resistance and extreme chemical inertness make it ideal for:

- Containers for storing and handling corrosive and reactive chemicals.

- Expansion joints in pipelines.

- Liners in hose assemblies and industrial pipelines.

PTFE’s unique combination of properties – low friction, chemical inertness, temperature resistance, and excellent electrical insulation – makes it a highly versatile material with a wide range of applications across various industries.

PTFE vs. Teflon: What’s in a Name

Whether you know it as PTFE or Teflon, this remarkable material boasts incredible versatility, finding its way into various PTFE products and applications across virtually every industry.

PTFE and Teflon are often used interchangeably, but they represent different aspects of the same material:

- PTFE

- Stands for Polytetrafluoroethylene.

- This is the chemical name for the compound.

- It describes the specific molecular structure of the polymer.

- Teflon

- A brand name for PTFE.

- Originally developed by DuPont, “Teflon” has become so synonymous with the material that it’s often used generically.

- Similar to how we call all tissues “Kleenex” or all photocopies “Xeroxes,” “Teflon” has become a widely recognized term for the material itself.

Think of it this way:

- PTFE is like the scientific name for the material.

- Teflon is like the brand name for a specific type of that material.

Key Takeaways:

- They are essentially the same substance.

- “Teflon” is a specific brand of PTFE manufactured by Chemours (formerly part of DuPont).

- While “Teflon” is a widely recognized and used term, it’s technically a brand name.

In essence:

When you’re discussing the chemical composition and properties of the material, you would use “PTFE.” When referring to a specific brand of PTFE, you would use “Teflon.”

Conclusion

In conclusion, while PTFE and Teflon are often used interchangeably, it’s important to understand that Teflon is a brand name for PTFE. Both materials offer exceptional properties like chemical resistance, high temperature tolerance, and low friction, making them invaluable in various industries.

Ready to experience the benefits of these remarkable materials? Kingdaflex offers a wide range of high-quality Teflon and PTFE hoses at wholesale prices. Contact us today to discuss your specific requirements and find the perfect solution for your application.

FAQs

Is Teflon the same as PTFE?

No, Teflon is a brand name that contains PTFE as its primary component.

Are Teflon-coated pans safe to use?

When used within recommended temperature limits, Teflon-coated pans pose no significant health risks.

What are the main applications of Teflon?

Teflon is commonly used as a nonstick coating in cookware and industrial applications.

Are Teflon and PTFE environmentally friendly?

Modern production techniques have significantly reduced the environmental impact of Teflon and PTFE products.