![]()

When it comes to fluid conveyance in various industries, hydraulic hoses play a crucial role.

These essential components enable the transfer of hydraulic fluids and power between different hydraulic components, allowing machinery and systems to operate effectively.

We will delve into the world of hydraulic hose supply, exploring its importance, types of hoses, key considerations, and where to find reliable suppliers. Whether you’re a business owner or an enthusiast, understanding hydraulic hoses is vital for maintaining optimal performance and safety in hydraulic systems.

Importance of Hydraulic Hose Supply

Hydraulic hoses serve as the lifelines of hydraulic systems, ensuring the smooth and efficient transfer of fluids and power. They are specifically designed to withstand high pressures and transmit hydraulic energy from one component to another. A reliable hydraulic hose supply is essential to maintain the integrity and performance of hydraulic systems. Without properly functioning hoses, leaks, pressure drops, and system failures can occur, leading to costly downtime and potential safety hazards.

Types of Hydraulic Hoses

There are various types of hydraulic hoses available, each designed for specific applications and operating conditions. Let’s explore some of the commonly used types:

SAE 100R1AT

The SAE 100R1AT hydraulic hose is suitable for medium pressure hydraulic applications. It is known for its excellent flexibility, abrasion resistance, and compatibility with petroleum and water-based hydraulic fluids.

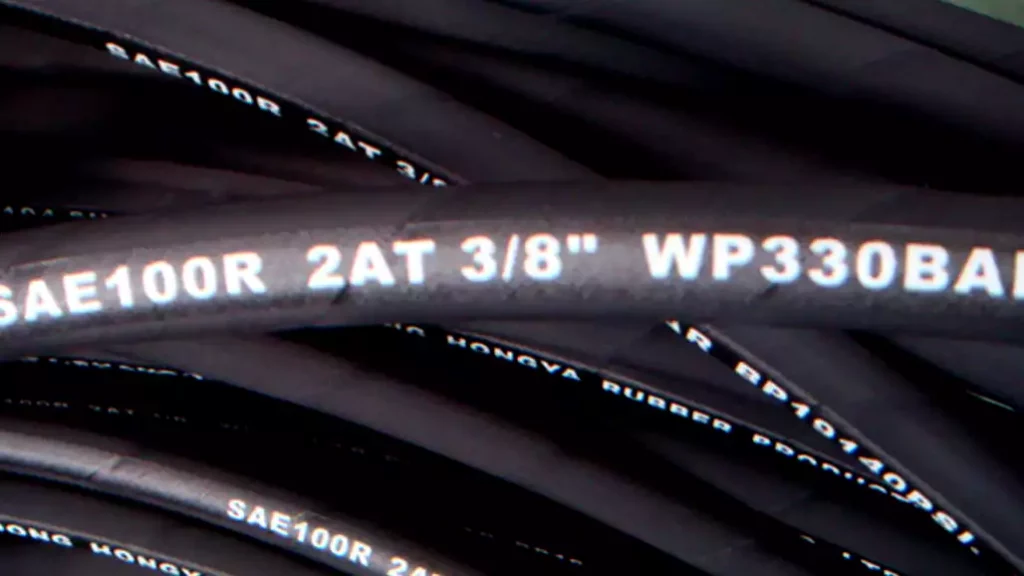

SAE 100R2AT

The SAE 100R2AT hydraulic hose offers higher pressure ratings compared to the R1AT hose. It is widely used in industrial and agricultural applications, providing reliable performance in demanding conditions.

SAE 100R9R

Designed for high-pressure hydraulic systems, the SAE 100R9R hose is engineered to withstand extreme conditions, including high temperatures and pulsating pressures.

SAE 100R12

The SAE 100R12 hydraulic hose is specifically designed for high-pressure applications, often found in heavy-duty machinery and equipment. It offers excellent resistance to abrasion and delivers reliable performance under demanding conditions.

SAE 100R13

With its six spiral layers of reinforcement, the SAE 100R13 hose provides exceptional strength and durability. It is ideal for heavy machinery and systems subjected to high-pressure requirements.

SAE 100R15

The SAE 100R15 hose is designed for applications that require both high-pressure and high-temperature resistance. Its construction and reinforcement provide enhanced durability and reliability.

SAE 100R17

The SAE 100R17 hydraulic hose is a compact and lightweight option suitable for applications with moderate pressure requirements. Its smaller bend radius makes it ideal for installations in tight spaces.

SAE 100R14

Known as the Teflon hose, the SAE 100R14 offers excellent chemical resistance and operates effectively in extreme temperatures. It is commonly used in applications that involve aggressive fluids and chemicals.

SAE 100R16

The SAE 100R16 hydraulic hose is designed for moderate to high-pressure applications. It provides reliable performance and flexibility, making it suitable for a wide range of industries.

SAE 100R5

The SAE 100R5 hose combines the benefits of hydraulic and textile hoses, making it versatile and suitable for both hydraulic and air brake system applications.

SAE 100R3

The SAE 100R3 hydraulic hose is used for low-pressure applications, such as return lines and power steering lines. It offers excellent resistance to oil and weather conditions.

SAE 100R6

The SAE 100R6 hose is ideal for low-pressure hydraulic applications. It provides reliable performance and flexibility while maintaining cost-effectiveness.

Factors to Consider When Choosing Hydraulic Hoses

When selecting hydraulic hoses for your specific application, several factors should be taken into consideration:

Pressure Rating

Ensure that the hydraulic hose has the appropriate pressure rating to withstand the operating pressures of your hydraulic system. Choosing a hose with a higher pressure rating than required is generally recommended for safety and durability.

Temperature Range

Consider the temperature range in which the hydraulic hose will operate. Some applications may require hoses that can withstand extreme temperatures, while others may require hoses with specific temperature limitations.

Compatibility

Ensure that the hydraulic hose is compatible with the hydraulic fluids used in your system. Different types of hoses have different compatibility requirements, so it’s crucial to choose the right hose material for your specific fluids.

Flexibility

Consider the flexibility requirements of your application. Flexible hoses are easier to install and route, especially in tight spaces. However, applications with high vibration or movement may require hoses with more rigidity.

Length and Size

Determine the required length and size of the hydraulic hose based on your system’s layout and fluid flow requirements. Proper hose length and size are crucial to ensure optimal performance and efficiency.

Hose End Connections

Consider the type of hose end connections required for your system. Various fittings and couplings are available to ensure secure and leak-free connections between hoses and other hydraulic components.

Reliable Hydraulic Hose Suppliers

When it comes to sourcing hydraulic hoses and related products, it is essential to choose reliable suppliers that offer high-quality products and excellent customer service. Here are some reputable hydraulic hose suppliers known for their industry expertise and product reliability:

- Hydraulics Direct: With decades of experience in the hydraulic industry, they provide a comprehensive range of hydraulic hoses, fittings, and accessories. They prioritize customer satisfaction and offer customized solutions for various applications.

- Kurt Hydraulic: As a leading supplier in the hydraulic hose market, Kurt Hydraulic offers a wide selection of hoses and fittings, including specialized hoses for specific industries. Their commitment to quality and innovation has earned them a solid reputation in the industry.

- Hose and Fittings Supply: Known for its extensive inventory and prompt delivery, Hose and Fittings Supply is a reliable source of hydraulic hoses and fittings. They stock a variety of brands and can assist in selecting the right hose for your specific needs.

- Kingdaflex: With a focus on customer-centric service as a leading hydraulic hose manufacturer, Kingdaflex provides a wide range of hydraulic hoses and accessories. They have a knowledgeable team that can assist in selecting the appropriate hose for your application and offer competitive pricing.

- Discount Hydraulic Hose: Specializing in hydraulic solutions, Discount Hydraulic Hose is known for its high-quality hoses and reliable customer support. They offer a comprehensive product catalog and have the expertise to provide tailored solutions for various industries.

Remember to research and compare different suppliers to find the one that best suits your requirements in terms of product quality, availability, pricing, and customer support.

Conclusion

Hydraulic hose supply is a crucial aspect of maintaining the performance and safety of hydraulic systems. By understanding the importance of hydraulic hoses, exploring the different types available, and considering key factors when choosing hoses, you can ensure reliable fluid conveyance and optimal system performance. Remember to source your hydraulic hoses from reputable suppliers known for their quality products and excellent customer service.

FAQs

Are hydraulic hoses interchangeable between different manufacturers?

Hydraulic hoses are not always interchangeable between manufacturers. It’s essential to consult the manufacturer’s specifications and guidelines to ensure compatibility and proper performance.

How often should hydraulic hoses be inspected and replaced?

Regular inspection of hydraulic hoses is crucial to identify signs of wear, damage, or leaks. Depending on the operating conditions, hoses may need to be replaced every 1 to 2 years or sooner if any issues are detected.

Can hydraulic hoses handle high-temperature fluids?

Some hydraulic hoses are specifically designed to withstand high-temperature fluids, but not all hoses are suitable for extreme heat. It’s important to choose hoses with the appropriate temperature ratings for your application.

What are some common causes of hydraulic hose failure?

Common causes of hydraulic hose failure include excessive pressure, abrasion, incorrect installation, chemical degradation, and age-related wear. Regular maintenance and proper usage can help minimize the risk of hose failure.

Are there alternatives to hydraulic hoses for fluid conveyance?

Depending on the specific application, alternatives to hydraulic hoses, such as pneumatic systems or mechanical linkages, may be considered. However, hydraulic hoses remain the most common and efficient method for fluid conveyance in many industries.