When it comes to hoses, especially in industrial and commercial settings, there’s a crucial distinction: suction and discharge hoses. While they might look similar at first glance, they serve distinct purposes and have specific characteristics.

This article will delve into the fundamental differences between suction and discharge hoses, helping you choose the right one for your needs.

What is A Suction Hose?

A suction hose is a flexible tube designed to create a vacuum and transfer liquids, gases, or solids from one location to another.

It works by using the principle of negative pressure, drawing materials into the hose through a suction force.

Key characteristics of suction hoses include:

- Vacuum resistance: They are built to withstand the negative pressure created by a pump or other suction device without collapsing.

- Flexibility: They are typically flexible to allow for easy handling and maneuvering in various applications.

- Abrasion resistance: The material used in suction hoses is often resistant to abrasion, ensuring durability in harsh environments.

- Chemical resistance: Depending on the specific application, suction hoses can be made from materials that are resistant to chemicals and corrosives.

Common applications for suction hoses include:

- Industrial processes: Transferring liquids or slurries in manufacturing plants, refineries, and chemical facilities.

- Construction: Pumping water from excavation sites or transporting materials.

- Agriculture: Moving liquids or slurries for irrigation or livestock feeding.

- Firefighting: Drafting water from static sources like ponds or rivers.

- Food and beverage industry: Transferring liquids in food processing plants.

Suction hoses are essential tools in many industries, providing efficient and reliable means of transferring materials.

What is A Discharge Hose?

A discharge hose is a flexible tube used to transport liquids, gases, or solids away from a source or process.

It is typically connected to the outlet or discharge port of a pump, compressor, or other equipment that generates pressure.

Key characteristics of discharge hoses include:

- Pressure resistance: They are designed to withstand the positive pressure generated by the equipment they are connected to.

- Flexibility: Like suction hoses, discharge hoses are often flexible for easy handling and maneuvering.

- Abrasion resistance: They are typically made from materials that are resistant to abrasion, ensuring durability in various applications.

- Chemical resistance: Depending on the specific application, discharge hoses can be made from materials that are resistant to chemicals and corrosives.

Common applications for discharge hoses include:

- Industrial processes: Transferring liquids or gases in manufacturing plants, refineries, and chemical facilities.

- Construction: Pumping water or other materials to construction sites.

- Agriculture: Transporting liquids or slurries for irrigation or livestock feeding.

- Firefighting: Delivering water from fire trucks to extinguish fires.

- Food and beverage industry: Transporting liquids or gases in food processing plants.

In essence, discharge hoses are the conduits that carry materials away from their source, playing a vital role in various industries and applications.

Difference Between Suction and Discharge Hose

Suction and discharge hoses are essential components in fluid transfer systems, yet they serve distinct purposes. Understanding their differences helps ensure proper selection for pumping, dewatering, and industrial operations where reliable performance and durability are crucial for efficiency and safety.

Function

Suction hoses are designed to draw fluids into the pump from a source such as a tank, pit, or reservoir. They create negative pressure and must resist collapsing under vacuum conditions, making their structure stronger and more rigid.

Discharge hoses, on the other hand, expel the pumped fluid from the pump to the desired destination. They operate under positive pressure, requiring flexibility and strength to handle continuous flow and pressure surges effectively.

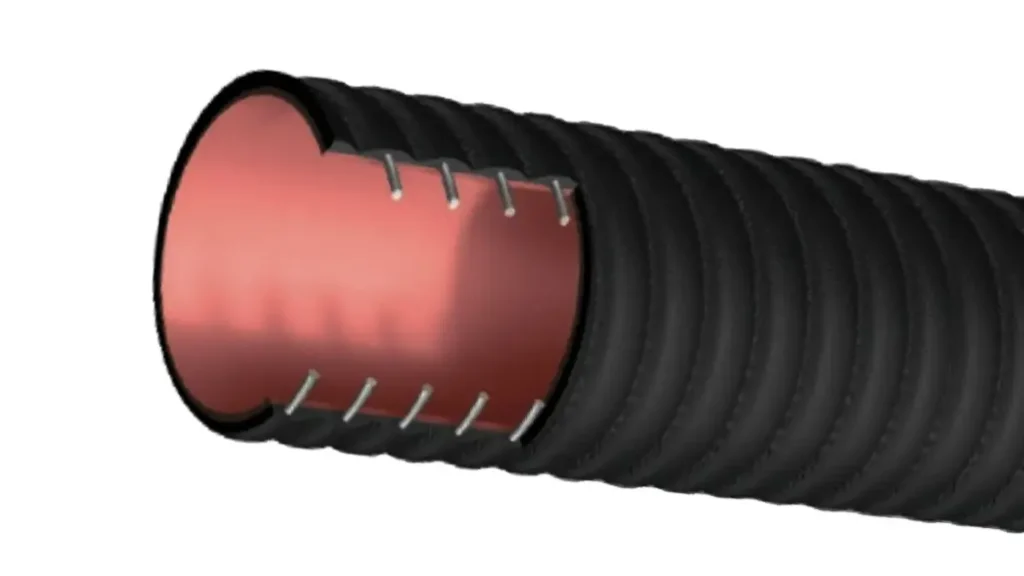

Construction

Suction hoses feature thick, rigid walls with embedded helix reinforcement—often steel or PVC—to prevent collapse during suction. Their durable structure ensures stability even under heavy vacuum loads or rough working environments.

Discharge hoses have more flexible walls designed for high-pressure discharge applications. They may include textile or wire reinforcement, providing strength while maintaining bendability for easier handling during operation or storage.

Pressure Handling

Suction hoses handle low or negative pressure created during fluid intake. Their ability to withstand vacuum pressure ensures consistent suction without deformation or flow interruption.

Discharge hoses handle high positive pressure generated when the pump pushes fluid out. They must resist bursting and maintain consistent flow during continuous pumping operations, ensuring safe discharge performance.

Applications

Suction hoses are used in applications like dewatering pits, transferring muddy water, or pumping chemicals from tanks. They’re vital in agriculture, construction, and wastewater systems where fluid intake is critical.

Discharge hoses are used for transferring fluids away from pumps, irrigation systems, or industrial drainage. Their flexibility and pressure resistance make them ideal for heavy-duty water discharge or slurry removal.

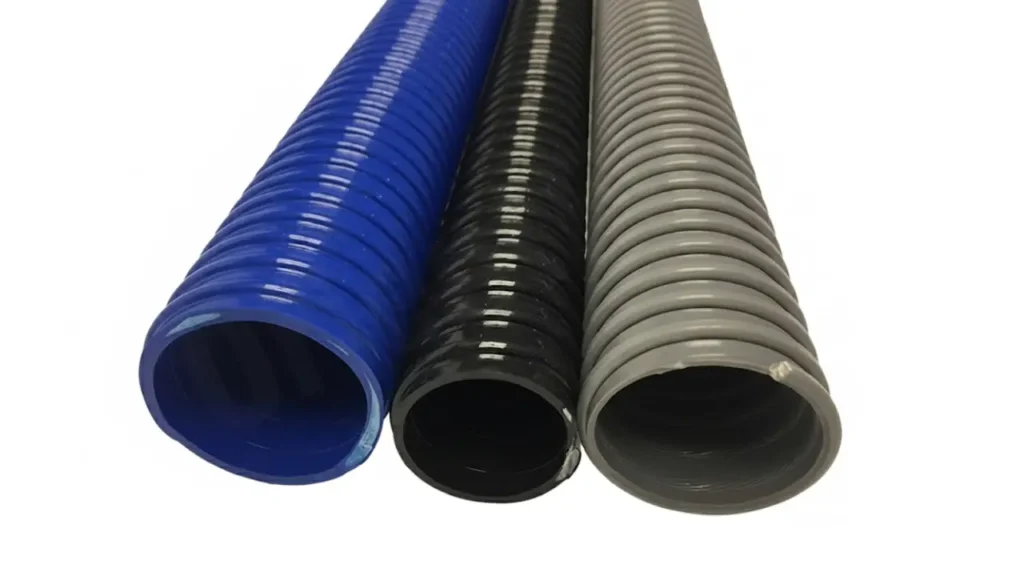

Material and Flexibility

Suction hoses are made from rigid PVC, rubber, or reinforced polyethylene to withstand external pressure while maintaining shape. Their limited flexibility ensures strength during vacuum suction.

Discharge hoses use softer, flexible materials like rubber or thermoplastic, allowing easy movement and installation. Their lightweight structure makes them suitable for portable or mobile pumping setups.

| Aspect | Suction Hose | Discharge Hose |

|---|---|---|

| Function | Draws fluid into the pump under vacuum pressure | Expels fluid from the pump under positive pressure |

| Construction | Thick, rigid walls with helix reinforcement | Flexible walls with textile or wire reinforcement |

| Pressure Type | Handles vacuum or negative pressure | Handles positive discharge pressure |

| Applications | Used for dewatering, chemical suction, or fluid intake | Used for fluid delivery, drainage, and irrigation |

| Flexibility | More rigid, less flexible | Highly flexible and easy to handle |

Suction & Discharge Hose

Suction and discharge hoses are essential components in various industrial and commercial applications. They are designed to transfer liquids, gases, or solids between different locations. While they may appear similar, they serve distinct purposes based on their operating principles and applications.

Suction Hose

A suction hose is designed to create a vacuum and draw materials into a system. It is typically connected to the inlet of a pump or other suction device. Key characteristics of suction hoses include:

- Negative pressure: They operate under negative pressure to create a vacuum.

- Inlet connection: They are connected to the inlet of a pump or other suction device.

- Applications: Common applications include drafting water from static sources, transferring liquids or slurries, and pumping out tanks or reservoirs.

Discharge Hose

A discharge hose is designed to transport materials out of a system. It is typically connected to the outlet of a pump or other discharge device. Key characteristics of discharge hoses include:

- Positive pressure: They operate under positive pressure to push materials out of a system.

- Outlet connection: They are connected to the outlet of a pump or other discharge device.

- Applications: Common applications include delivering water to a fire, transporting liquids or gases, and filling tanks or reservoirs.

Key Differences:

| Feature | Suction Hose | Discharge Hose |

|---|---|---|

| Pressure | Negative pressure | Positive pressure |

| Connection | Inlet of a pump | Outlet of a pump |

| Function | Draws materials into a system | Pushes materials out of a system |

Choosing the Right Hose:

When selecting a suction or discharge hose, consider the following factors:

- Material: The hose material should be compatible with the substances being transferred and resistant to abrasion, chemicals, and temperature extremes.

- Pressure rating: The hose should be able to withstand the required pressure for the application.

- Size: The hose diameter should be appropriate for the flow rate and the size of the connected equipment.

- Length: The hose should be long enough to reach the desired location.

- Reinforcement: Reinforced hoses provide additional strength and durability.

By understanding the differences between suction and discharge hoses and carefully considering these factors, you can choose the right hose for your specific needs.

Would you like to know more about specific applications for suction or discharge hoses?

Conclusion

In conclusion, understanding the differences between suction and discharge hoses is crucial for selecting the appropriate hose for your specific application. Suction hoses are designed to draw materials into a system, while discharge hoses are designed to push materials out of a system. By carefully considering factors such as material, pressure rating, size, length, and reinforcement, you can ensure that you choose the right hose for your needs.

Are you in need of high-quality suction or discharge hoses for your industrial or commercial application? Look no further than Kingdaflex.

Our extensive range of hoses is designed to meet the most demanding requirements. Contact us today to discuss your specific needs and find the perfect hose solution for your business.