Hydraulic hoses are essential in countless industries, from construction and agriculture to manufacturing and mining. Their ability to withstand high pressures, harsh environments, and the relentless demands of hydraulic systems depends heavily on the rubber compound used in their construction.

One of the most critical processes in hydraulic hose manufacturing is rubber vulcanization. This chemical reaction transforms raw rubber into a durable, elastic material capable of withstanding the rigors of hydraulic applications.

In this blog post, we’ll delve into the world of rubber vulcanization, exploring:

- The vulcanization process: A step-by-step breakdown of how rubber is transformed into a durable material.

- Vulcanizing agents: The chemicals that drive the vulcanization reaction.

- The impact of vulcanization on hydraulic hose properties: How vulcanization affects factors like strength, elasticity, and heat resistance.

- Vulcanization methods: Different techniques used to cure rubber, including steam curing, hot air curing, and autoclave curing.

By understanding the science behind rubber vulcanization, we can gain a deeper appreciation for the craftsmanship and technology that goes into creating high-performance hydraulic hoses. So, let’s embark on a journey through the world of rubber vulcanization and discover its essential role in hydraulic hose manufacturing.

What Is Rubber Vulcanization

Rubber vulcanization is a chemical process that transforms raw rubber into a more durable and elastic material. It involves the formation of cross-links between the rubber molecules, creating a stronger and more resilient structure.

This process is essential for giving rubber its unique properties, such as:

- Elasticity: The ability to stretch and return to its original shape.

- Strength: Resistance to tearing and breaking.

- Durability: The ability to withstand wear and tear.

- Heat resistance: The ability to maintain its properties at high temperatures.

Without vulcanization, raw rubber would be soft, sticky, and easily damaged. Vulcanization makes it suitable for a wide range of applications, including hydraulic hoses, tires, gaskets, and other rubber products.

Hydraulic Hose Vulcanizer

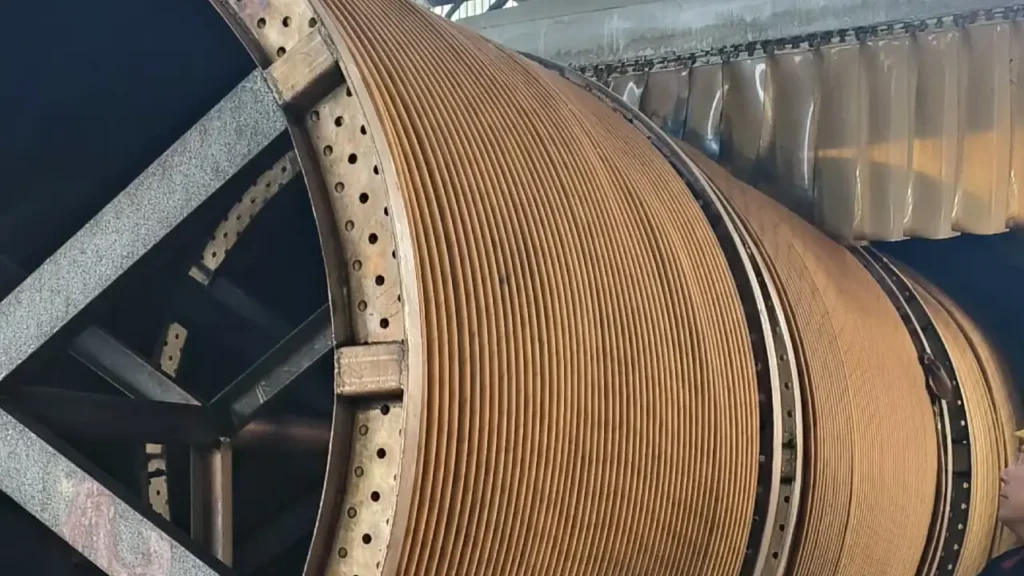

A hydraulic hose vulcanizer is a specialized piece of equipment used to cure and strengthen hydraulic hoses.

The hydraulic hose vulcanization process involves applying heat and pressure to a hose assembly to cross-link the rubber molecules, enhancing its durability, flexibility, and resistance to various environmental factors.

Key Components of a Hydraulic Hose Vulcanizer:

- Vulcanizing Press: This component applies the necessary pressure to the hose during the curing process.

- Heating System: This system provides the heat required to initiate the cross-linking reaction.

- Temperature Control: Precise temperature control is essential for optimal vulcanization.

- Pressure Control: Accurate pressure control ensures consistent curing and prevents damage to the hose.

The Vulcanization Process:

- Hose Assembly: The hose assembly, consisting of the inner tube, reinforcement layers, and outer cover, is prepared for vulcanization.

- Molding: The assembly is placed in a mold that imparts the desired shape and size to the hose.

- Curing: The mold is placed in the vulcanizer, where it is subjected to heat and pressure.

- Cooling: After the curing cycle, the hose is cooled to room temperature.

- Post-Processing: The hose is inspected, tested, and packaged for shipment.

Importance of Vulcanization:

- Durability: Vulcanization significantly improves the hose’s resistance to abrasion, cuts, and other forms of damage.

- Flexibility: The process enhances the hose’s flexibility, allowing it to bend and twist without cracking.

- Pressure Resistance: Vulcanization increases the hose’s ability to withstand high pressures.

- Temperature Resistance: The process improves the hose’s resistance to extreme temperatures.

By utilizing advanced hydraulic hose vulcanizers, manufacturers can produce high-quality hoses that meet the demanding requirements of various industries, including construction, agriculture, and manufacturing.

Why Is Rubber Vulcanization for Hydraulic Hose

Rubber vulcanization is essential for hydraulic hoses because it provides the following key benefits:

- Durability: Vulcanization strengthens the rubber, making it resistant to tearing, abrasion, and other forms of wear and tear. This is crucial for hydraulic hoses, which often operate in demanding environments.

- Elasticity: Vulcanization gives rubber its elasticity, allowing it to stretch and flex without breaking. This is important for hydraulic hoses, as they must be able to bend and twist to accommodate different hydraulic system configurations.

- Heat Resistance: Vulcanized rubber can withstand higher temperatures than raw rubber. This is essential for hydraulic hoses that operate in hot environments or under high pressures.

- Chemical Resistance: Vulcanization can improve the rubber’s resistance to chemicals, which is important for hydraulic hoses that come into contact with various hydraulic fluids and other substances.

- Oil Resistance: Vulcanization can make rubber more resistant to oils, which is crucial for hydraulic hoses that transport hydraulic fluids.

In summary, rubber vulcanization is a critical process that gives hydraulic hoses the necessary properties to perform reliably in demanding environments and withstand the pressures and stresses associated with hydraulic systems.

Rubber Vulcanization Process for Hydraulic Hose Manufacturing

Rubber vulcanization is a crucial step in the manufacturing of hydraulic hoses. It involves the chemical transformation of raw rubber into a durable, elastic material capable of withstanding the high pressures and harsh environments encountered in hydraulic systems.

Here’s a breakdown of the rubber vulcanization process for hydraulic hose manufacturing:

1. Compound Preparation:

- Raw Rubber: Natural or synthetic rubber is selected based on the specific requirements of the hydraulic hose, such as pressure resistance, temperature tolerance, and chemical compatibility.

- Vulcanizing Agents: Sulfur or peroxides are added to the rubber compound to initiate the vulcanization process.

- Other Ingredients: Additional ingredients like fillers, reinforcements, and antioxidants may also be included to enhance the rubber’s properties.

2. Mixing:

- Banbury Mixer or Internal Mixer: The rubber compound is mixed using a high-intensity mixer to ensure even distribution of the ingredients.

3. Extrusion:

- Extruder: The mixed rubber compound is forced through a die to create a continuous length of hose.

4. Vulcanization:

- Curing Chamber: The extruded hose is placed in a curing chamber, where it is subjected to heat and pressure.

- Vulcanization Reaction: The heat and pressure cause the vulcanizing agents to create cross-links between the rubber molecules, transforming the raw rubber into a vulcanized material.

- Curing Time: The curing time depends on the specific rubber compound and the desired properties of the hose.

5. Testing and Inspection:

- Quality Control: The vulcanized hoses undergo rigorous testing to ensure they meet specific standards for burst pressure, tensile strength, and other performance parameters.

Vulcanization methods used in hydraulic hose manufacturing include:

- Steam Curing: The hoses are cured in a steam-filled chamber.

- Hot Air Curing: The hoses are cured in a chamber heated by hot air.

- Autoclave Curing: The hoses are cured in a high-pressure chamber.

The choice of vulcanization method depends on factors such as the desired properties of the hose, the size of the production run, and the available equipment.

By carefully controlling the rubber vulcanization process, manufacturers can produce hydraulic hoses that are durable, reliable, and capable of withstanding the demanding conditions encountered in hydraulic systems.

Conclusion

Rubber vulcanization is a critical process in the manufacturing of hydraulic hoses, transforming raw rubber into a durable, elastic material capable of withstanding the demanding conditions of hydraulic systems. By understanding the science behind rubber vulcanization and the various methods used, we gain a deeper appreciation for the craftsmanship and technology involved in producing these essential components.

Are you in need of premium hydraulic hoses that are engineered for exceptional performance and durability? Look no further than Kingdaflex. As a leading manufacturer of hydraulic hoses, Kingdaflex utilizes advanced rubber vulcanization techniques to produce hoses that meet the highest industry standards.

Contact us today to discuss your specific requirements and explore our extensive range of hydraulic hose solutions. Our team of experts can help you select the ideal hoses for your application, ensuring optimal efficiency and reliability.

Visit our website or contact our sales team to learn more about Kingdaflex and our premium hydraulic hoses.