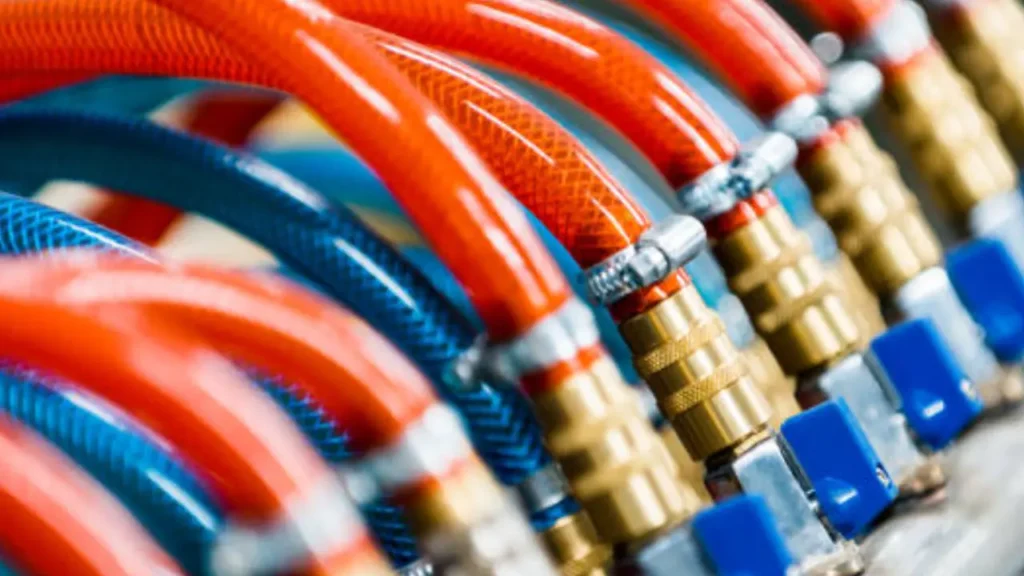

Fuel hoses are essential components in automotive, industrial, and marine systems, ensuring the safe transfer of gasoline, diesel, or other fuels. Understanding fuel hose types helps you choose the right hose based on material, size, and pressure requirements, reducing the risk of leaks, contamination, or system failure.

Different fuel hoses serve specific applications depending on the environment and fuel type. Rubber, PVC, and reinforced hoses each offer unique benefits, while size and flexibility determine compatibility with vehicles, machinery, or fuel storage systems. Knowing these differences ensures optimal performance, durability, and safety in fuel handling operations.

What are Fuel Hoses?

Fuel hoses are flexible tubes designed to safely transport gasoline, diesel, or other fuels from storage tanks to engines or machinery. They are engineered to resist pressure, heat, and chemical corrosion, ensuring leak-free fuel flow. Fuel hoses come in various materials and sizes, tailored for automotive, industrial, and marine applications.

Fuel Hose Types

Fuel hoses come in various materials and constructions, each designed for specific applications and performance requirements. Understanding these types helps you select the right hose for safety, durability, and efficiency in fuel handling. Below, we explore the main fuel hose types, their benefits, and typical applications.

Rubber Fuel Hoses

Rubber fuel hoses are flexible, durable, and resistant to gasoline, diesel, and oil. They can handle moderate pressures and temperatures, making them a versatile choice for many vehicles and machinery.

Benefits: Rubber hoses offer excellent flexibility, abrasion resistance, and compatibility with different fuels. They are easy to install and maintain, providing a cost-effective solution for everyday fuel transfer needs.

Applications: Commonly used in cars, trucks, motorcycles, and small engines, rubber fuel hoses are ideal for fuel lines, vent lines, and low-pressure fuel systems. They are also suitable for some industrial equipment.

PVC Fuel Hoses

PVC (polyvinyl chloride) fuel hoses are lightweight and resistant to corrosion, making them ideal for clean fuel applications. They are less flexible than rubber but provide good chemical resistance.

Benefits: PVC hoses are affordable, lightweight, and resistant to many chemicals and UV exposure. They maintain shape under normal operating conditions and are easy to cut and connect.

Applications: PVC hoses are often used for fuel transfer in light-duty vehicles, boats, and fuel storage systems where chemical resistance and cost-efficiency are priorities.

Reinforced Fuel Hoses

Reinforced fuel hoses feature multiple layers, often including braided fabric or metal, to handle higher pressures and extreme conditions. These hoses are robust and reliable for demanding applications.

Benefits: Reinforced hoses provide high pressure resistance, excellent durability, and long service life. They prevent kinking or collapse under vacuum conditions and maintain consistent fuel flow.

Applications: They are used in trucks, heavy machinery, marine engines, and racing vehicles. Reinforced hoses are ideal for high-pressure fuel injection systems and industrial fuel transfer lines.

Teflon (PTFE) Fuel Hoses

Teflon fuel hoses are chemically resistant, heat-tolerant, and non-reactive, suitable for high-performance and harsh environments. They are often used where precise fuel delivery is critical.

Benefits: Teflon hoses resist extreme temperatures, chemical corrosion, and pressure fluctuations. They maintain fuel purity and provide reliable performance in demanding conditions.

Applications: Common in motorsports, aviation, and industrial fuel systems, Teflon hoses are ideal for high-performance engines, turbocharged setups, and applications requiring high chemical and thermal resistance.

How to Choose Suitable Fuel Hoses?

Selecting the right fuel hose ensures safety, reliability, and optimal performance in fuel systems. Factors such as fuel type, pressure, temperature, and environmental conditions must be considered. Choosing the correct hose prevents leaks, contamination, and equipment damage while extending hose service life.

- Determine Fuel Type: Identify whether the hose will carry gasoline, diesel, or other fuels. Different fuels react differently with materials, so selecting a hose compatible with the specific fuel ensures chemical resistance, avoids degradation, and maintains fuel purity for reliable system performance.

- Check Pressure Ratings: Consider the operating pressure of the fuel system. Low-pressure hoses suit fuel lines in cars, while high-pressure systems require reinforced or braided hoses. Proper pressure rating ensures safety, prevents bursting, and maintains consistent fuel flow under varying operating conditions.

- Assess Temperature Range: Evaluate the temperature conditions where the hose will operate. Some hoses handle extreme heat or cold better than others. Choosing a hose that withstands the system’s temperature range prevents hardening, cracking, or deformation over time.

- Consider Environmental Factors: Determine exposure to UV, ozone, oil, or mechanical abrasion. Hoses in harsh environments require added protection or specific materials to resist wear, maintain flexibility, and ensure longevity, reducing maintenance and potential downtime.

- Size and Flexibility: Ensure the hose diameter matches fittings and flow requirements. Proper sizing ensures efficient fuel delivery, avoids leaks, and supports ease of installation. Flexible hoses also simplify routing in tight spaces without kinking or collapsing.

Conclusion

Understanding fuel hose types is crucial for anyone handling fuel systems. By choosing hoses based on material, size, and application, you can ensure safety, efficiency, and long-term performance. Proper selection reduces maintenance costs and prevents hazardous leaks, protecting both equipment and the environment.

At Kingdaflex, we provide a wide range of fuel hoses to meet diverse industrial, automotive, and marine requirements. Our hoses are designed for durability, flexibility, and reliable fuel transfer, making them an ideal choice for businesses seeking quality and consistency in bulk orders.

For wholesale fuel hoses, Kingdaflex offers competitive pricing, fast delivery, and customization options. Whether you need rubber, PVC, or reinforced hoses, we supply solutions tailored to your specific applications. Partner with us to secure reliable fuel hoses for large-scale operations and ensure uninterrupted fuel handling.