Understanding hydraulic fitting working pressure is paramount for ensuring the safety and efficiency of any hydraulic system. This guide will delve into the critical aspects of pressure ratings, helping you select the right fittings for your specific application. Improperly matched components can lead to catastrophic failures, costly downtime, and significant safety hazards.

We’ll explore the factors that determine a fitting’s pressure capacity, including material composition, design, and manufacturing processes. By grasping these concepts, you’ll be better equipped to interpret pressure ratings and make informed decisions that optimize your hydraulic system’s performance and longevity.

Hydraulic Fitting Pressure Ratings

Hydraulic fitting pressure ratings are critical specifications that indicate the maximum pressure a fitting can safely withstand during operation. These hydraulic fitting ratings ensure system integrity, prevent leaks, and safeguard against catastrophic failures. Understanding these ratings is fundamental for designing and maintaining reliable hydraulic systems.

Hydraulic Fitting Working Pressure

Working pressure, also known as operating pressure, is the continuous pressure under which a hydraulic fitting is designed to operate. This is the everyday pressure that the system will experience. It’s crucial to select fittings where the rated working pressure is equal to or greater than the maximum expected operating pressure of your hydraulic system to ensure longevity and prevent premature failure.

Hydraulic Fitting Burst Pressure

Burst pressure is the theoretical maximum pressure a hydraulic fitting can withstand before it physically ruptures or breaks. This rating is significantly higher than the working pressure, typically by a safety factor of 3:1 or 4:1. While a fitting should never intentionally be exposed to its burst pressure, this rating provides a critical safety margin against unexpected pressure surges or system malfunctions, indicating the ultimate strength of the component.

The Role of Proof Pressure

Proof pressure is a specific pressure that a hydraulic fitting is subjected to during manufacturing and testing, typically 1.5 to 2 times the working pressure. The fitting must withstand this pressure for a defined period without showing any signs of leakage or permanent deformation. This test confirms the fitting’s ability to handle pressures beyond its continuous operating range safely and ensures its structural integrity before it’s put into service.

Factors Affecting Hydraulic Fitting Pressure Ratings

Hydraulic fitting pressure ratings are not static; they are influenced by various environmental and operational conditions that can significantly impact a fitting’s ability to perform safely and effectively.

Overlooking these factors can lead to premature wear, reduced lifespan, and ultimately, system failure. A comprehensive understanding of these influences is essential for selecting the correct fittings and ensuring long-term reliability.

The primary factors affecting a fitting’s pressure rating include temperature, the type of hydraulic fluid, and the presence of pressure spikes. Each of these elements can individually or collectively degrade a fitting’s performance over time.

Temperature

Temperature is a critical factor because it directly affects the material properties of hydraulic fittings.

- High Temperatures: Elevated temperatures can weaken the metal and elastomer components of a fitting. As temperature increases, the tensile strength of metals decreases, making them more susceptible to deformation or rupture under pressure. Similarly, seals (O-rings, gaskets) made from rubber or polymer materials can soften, degrade, or lose their elasticity at high temperatures, leading to leaks. Excessive heat can also accelerate the aging and degradation of the fitting materials themselves.

- Low Temperatures: Conversely, extremely low temperatures can make fitting materials brittle and less flexible. This can lead to cracking or fracturing, especially if the system experiences shock or vibration. Seals may harden and shrink, compromising their sealing ability and leading to leaks. Operating fittings outside their specified temperature range significantly reduces their effective pressure capacity.

Fluid Type

The chemical composition and properties of the hydraulic fluid play a significant role in a fitting’s long-term integrity and pressure rating.

- Chemical Compatibility: Certain hydraulic fluids can be incompatible with the materials used in fittings and seals. This incompatibility can lead to chemical degradation, corrosion, swelling, or shrinking of elastomers, which compromises the seal’s integrity and reduces the fitting’s ability to hold pressure. For instance, some synthetic fluids might react adversely with common rubber seals if not specifically designed for that fluid.

- Viscosity: While not directly affecting the rated pressure, fluid viscosity at operating temperatures influences system efficiency and can indirectly affect pressure spikes. Fluids that are too thick or too thin can lead to increased friction, cavitation, or inadequate lubrication, all of which can place additional stress on fittings and potentially reduce their effective lifespan under pressure.

Pressure Spikes and Pulsation

Hydraulic systems are rarely subjected to a constant, steady pressure. They often experience rapid and sudden increases in pressure, known as pressure spikes or surges, and continuous pressure pulsation.

- Impact of Spikes: Pressure spikes, often caused by the sudden closing of valves, starting/stopping of pumps, or sudden load changes, can momentarily exceed the system’s normal working pressure, even approaching or exceeding the burst pressure of fittings if not properly accounted for. These transient events induce significant stress on fittings, leading to fatigue and micro-fractures over time, which can ultimately result in catastrophic failure.

- Fatigue: Continuous pressure pulsation, even at or below the rated working pressure, can cause material fatigue. The repeated expansion and contraction of the fitting materials due to pressure cycles can lead to the formation and propagation of cracks, progressively weakening the fitting’s structure and reducing its ability to withstand its rated pressure over its service life.

How to Calculate Hydraulic Fitting Pressure Ratings?

How to Calculate Hydraulic Fitting Pressure Ratings? 40 word beginning, and H3 outline subtitles, and don’t bold them, and write one paragraph about each step’s content

Calculating hydraulic fitting pressure ratings involves a combination of theoretical formulas, material properties, and rigorous testing to ensure safety and performance. Manufacturers typically provide these ratings, which are determined by a detailed engineering process. It’s crucial to understand the methods used to establish these values.

1. Determine Material Properties

The first step involves identifying the mechanical properties of the material used to manufacture the fitting. Key properties include:

- Tensile Strength: The maximum stress the material can withstand before breaking under tension.

- Yield Strength: The stress at which the material begins to deform permanently.

- Allowable Stress: A conservative stress value derived from the yield or tensile strength, often incorporating safety factors. This value is critical for design calculations, ensuring the fitting operates well within its elastic limits. Different materials, such as various grades of steel, brass, or stainless steel, will have distinct allowable stress values, directly impacting the potential pressure rating.

2. Geometric Considerations

The physical dimensions and design of the fitting significantly influence its ability to contain pressure.

- Wall Thickness: Thicker walls generally lead to higher pressure ratings as they provide more material to resist internal forces.

- Internal and External Diameters: These dimensions are crucial for calculating the cross-sectional area over which the pressure acts. Formulas like Lame’s formula, often used for thick-walled cylinders, relate the internal and external diameters, material stress, and pressure. A smaller internal diameter for a given external diameter (i.e., a thicker wall) will result in a higher pressure rating.

- Connection Type and Design: The specific design of the fitting’s connection (e.g., JIC flare, NPT thread, ORB) dictates how the seal is formed and how forces are distributed. Designs that achieve robust metal-to-metal seals or effectively compress O-rings contribute to higher pressure containment. Any stress concentrations in the design must also be considered.

3. Applying Safety Factors

Safety factors are integral to pressure rating calculations, providing a crucial margin against unexpected overpressure, material imperfections, and degradation over time.

- Working Pressure vs. Burst Pressure: Manufacturers typically establish a working pressure based on a safety factor applied to the burst pressure. A common safety factor for hydraulic fittings is 4:1, meaning the burst pressure is at least four times the rated working pressure. This ensures that even if the system experiences significant pressure surges, the fitting has a substantial reserve capacity before failure.

- Dynamic vs. Static Applications: The type of application (dynamic with pressure fluctuations vs. static with constant pressure) can influence the safety factor used. Dynamic applications often require higher safety factors due to the fatiguing effects of cyclic loading.

4. Rigorous Testing

While theoretical calculations provide a starting point, actual physical testing is indispensable for validating and establishing final pressure ratings.

- Hydrostatic Proof Testing: Fittings are subjected to a pressure significantly higher than their rated working pressure (e.g., 1.5 to 2 times) for a specified duration to ensure they can withstand such conditions without permanent deformation or leakage. This is a non-destructive test.

- Burst Testing: This is a destructive test where pressure is steadily increased until the fitting ruptures. The measured burst pressure is then used in conjunction with the safety factor to determine the working pressure.

- Impulse Testing (Cyclic Endurance Testing): To simulate real-world conditions with pressure fluctuations, fittings are subjected to repeated pressure cycles at elevated pressures (e.g., 133% of working pressure) for a large number of cycles (e.g., one million cycles). This test assesses the fitting’s fatigue resistance and long-term durability.

- Environmental Testing: Fittings may also undergo tests for temperature extremes, corrosion resistance (e.g., salt spray tests), and fluid compatibility to ensure their pressure ratings hold under various operating environments.

By combining these steps, manufacturers can accurately determine and certify the pressure ratings for hydraulic fittings, ensuring they meet the stringent safety and performance demands of hydraulic systems.

Hydraulic Fitting Working Pressure and Burst Pressure

Hydraulic fitting pressure ratings are fundamental for ensuring the safe and efficient operation of hydraulic systems. Two key terms, working pressure and burst pressure, define a fitting’s capacity to handle internal fluid forces. Understanding their distinction is vital for proper component selection and system design, preventing costly failures and ensuring operator safety.

Working Pressure

Working pressure, also referred to as operating pressure, is the maximum continuous pressure that a hydraulic fitting is designed to withstand during normal, day-to-day operation. This is the pressure level that the fitting is expected to endure reliably over its entire service life. It is the most commonly referenced pressure rating for practical application and selection, ensuring the fitting can handle the typical demands of the hydraulic system without compromising its integrity or leading to leaks.

Burst Pressure

Burst pressure represents the absolute maximum pressure a hydraulic fitting can tolerate before it physically ruptures or fails catastrophically. This is a destructive limit, typically much higher than the working pressure, and is determined through rigorous testing where pressure is increased until failure occurs. The burst pressure provides a critical safety margin, usually a multiple (e.g., 4:1) of the working pressure, to account for unexpected pressure spikes, manufacturing variations, and potential material degradation over time, preventing immediate failure in extreme conditions.

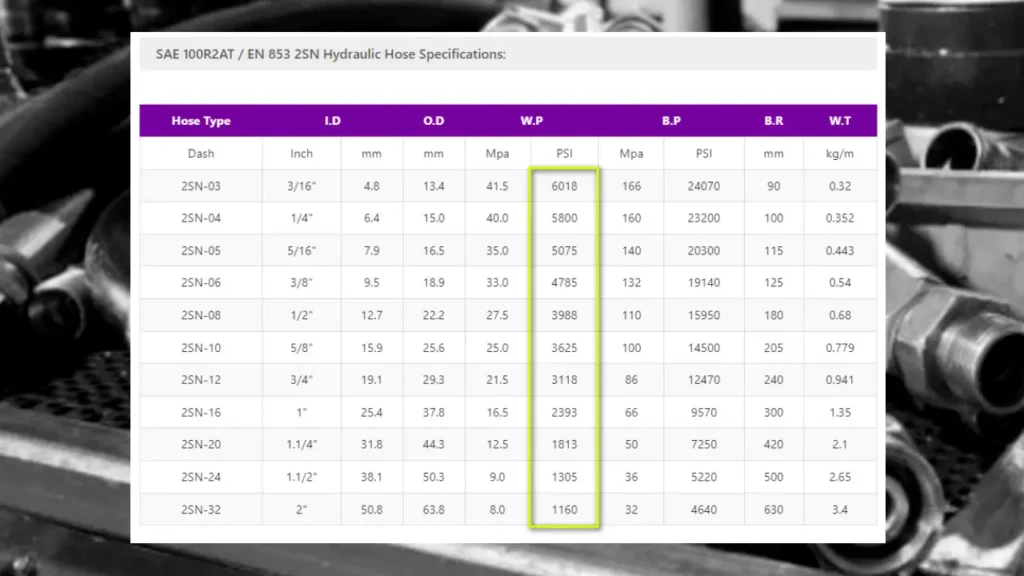

Here’s a table of the two hydraulic fitting pressure ratings:

| Feature | Working Pressure | Burst Pressure |

| Definition | Maximum continuous operating pressure | Maximum pressure before catastrophic failure |

| Purpose | Ensures safe daily operation | Provides a safety margin against extreme pressure |

| Relation to other | Lower than burst pressure (e.g., 1/4 of burst) | Higher than working pressure (e.g., 4x working) |

| Test Type | Verified through impulse/cyclic endurance tests | Determined by destructive hydrostatic tests |

| System State | Normal operational conditions | Extreme, short-duration pressure events |

Conclusion

Understanding hydraulic fitting working pressure is paramount for system integrity and safety. This guide emphasized that selecting fittings with appropriate pressure ratings, exceeding the system’s maximum operating pressure, prevents leaks and catastrophic failures. Mismatched components compromise performance and endanger personnel.

Crucially, factors like temperature, fluid type, and pressure spikes influence effective pressure ratings. Always consult manufacturer specifications and industry standards to ensure compatibility and robust system design, mitigating risks associated with pressure fatigue and material degradation.

For reliable hydraulic system construction, prioritize quality components. You can buy bulk hydraulic fittings from Kingdaflex, ensuring access to a wide range of fittings that meet stringent pressure requirements for diverse applications.