A hydraulic hose blowout is a sudden and catastrophic failure that can bring an entire operation to a halt. It not only results in expensive downtime and fluid loss but also poses a serious safety risk to personnel. Understanding the causes behind a blowout is the first step toward preventing one.

This blog post will delve into the most common reasons why hydraulic hoses fail, from pressure surges to improper installation. We will also provide practical prevention strategies and effective solutions to help you mitigate the risks associated with blowouts and maintain a safer, more reliable system.

What Are Hydraulic Hoses?

Hydraulic hoses are flexible tubes designed to transport hydraulic fluid between various components within a hydraulic system. These hoses are specifically engineered to withstand high-pressure conditions, making them crucial components in a wide range of industrial and machinery applications.

The primary function of hydraulic hoses is to transmit hydraulic power from one part of a hydraulic system to another. This power transmission enables the operation of machinery, equipment, and tools used in various industries such as construction, manufacturing, agriculture, and aviation.

Hydraulic hoses are typically constructed using several layers of materials, including an inner tube, reinforcement layers (usually made of high-strength materials like steel or synthetic fibers), and an outer cover. The inner tube is in direct contact with the hydraulic fluid and needs to be compatible with the type of fluid used in the system.

Due to their flexibility, hydraulic hoses can be routed through complex machinery and equipment, allowing for the efficient transmission of hydraulic energy to perform tasks such as lifting heavy loads, bending metal, operating construction equipment, and even controlling the landing gear of aircraft.

Why Do Hydraulic Hoses Blow?

Hydraulic hoses can fail catastrophically for a variety of reasons, often due to a combination of factors that compromise the hose’s structural integrity. These failures, known as blowouts, are not only a major cause of equipment downtime but also pose significant safety risks due to the high-pressure fluid involved. Understanding the root causes of these failures is essential for effective prevention and maintenance.

Improper Installation: Mistakes during installation are a major factor in premature hose failure. A hydraulic hose that is twisted, bent too tightly, or paired with mismatched fittings experiences significant stress concentrations. These improper conditions can cause the hose to fail well before the end of its intended service life.

Age and Wear: One of the most common causes of a hydraulic hose blowout is the natural aging and wear of the hose material over time. Constant exposure to pressure cycles, heat, and environmental factors like ozone and UV radiation can gradually degrade the rubber and reinforcement, leading to a loss of strength.

Excessive Pressure: A hydraulic hose is designed to handle a specific maximum working pressure. Operating the system at pressures that exceed this rating, or experiencing unexpected pressure spikes, places extreme stress on the hose’s reinforcement layers, causing them to fail suddenly and violently.

Abrasion and Friction: External damage is a leading cause of blowouts. When a hydraulic hose rubs against other components, sharp edges, or abrasive surfaces, its outer cover wears away. Once the protective cover is gone, the reinforcement layer is exposed and quickly damaged, leading to a blowout.

High Temperatures: Extreme temperatures, whether from the fluid being too hot or the external environment being too cold, can severely affect the hose’s material properties. High heat can cause the rubber to harden and crack, while extreme cold can make it brittle and susceptible to fracture under pressure.

Here is the video showing the case of hydraulic hose blow out.

What Causes a Hose to Burst?

A hydraulic hose blowout is a catastrophic failure that can be caused by a variety of factors, often occurring when the hose’s structural integrity is compromised. These failures are a significant safety risk due to the high pressures and hot fluids involved. The most common causes of a hydraulic hose bursting include:

- Excessive Pressure: A hydraulic system operating beyond the hose’s maximum rated working pressure is the most direct cause of a blowout. This can happen due to system malfunctions, sudden pressure surges, or an incorrect pressure setting on the relief valve.

- Abrasion and External Damage: The outer cover of a hydraulic hose is its first line of defense. When it rubs against other parts of the machine, sharp edges, or is subjected to external impacts, the outer layer can wear away. Once the inner reinforcement wires are exposed, they are highly susceptible to corrosion and damage, leading to a blowout.

- Age and Wear: Like any component, a hydraulic hose has a finite lifespan. Over time, constant pressure cycling, flexing, and exposure to environmental factors like UV rays, ozone, and extreme temperatures will degrade the hose material. This natural aging process weakens the hose from the inside out, making it more prone to bursting.

- Improper Installation: Installation errors are a leading cause of premature hydraulic hose failure. Bending a hydraulic hose too tightly beyond its minimum bend radius can cause kinking and damage the reinforcement layers. Twisting the hose during installation, even by a few degrees, can significantly reduce its lifespan and lead to a blowout.

- Temperature Extremes: Operating a hydraulic hose in an environment that is either too hot or too cold can have a detrimental effect. High heat can cause the hose material to harden, crack, and become brittle, while extreme cold can make it rigid and prone to failure when flexed under pressure.

- Chemical Incompatibility: Using a hydraulic fluid that is not compatible with the hose’s inner tube material can cause the tube to swell, deteriorate, or become spongy from the inside. This internal degradation weakens the hose’s structure and can lead to a sudden burst.

Hydraulic Hose Blow Out Types

A hydraulic hose blowout is not a single type of event, but rather a catastrophic failure that can manifest in several ways, each with a different root cause. Understanding these different types of blowouts is crucial for effective diagnosis and prevention. The appearance of the failed hose often provides clues about the underlying problem, helping technicians choose the right replacement and avoid future failures.

- Pressure-Related Blowout: This type of blowout is often characterized by a clean, longitudinal split or a sudden rupture along the hose body. It typically occurs when a pressure spike or a system running beyond its rated capacity exceeds the hose’s burst pressure, causing the reinforcement layers to fail under extreme stress.

- Abrasion-Induced Blowout: An abrasion-related blowout appears as a hole or wear spot where the outer cover has been rubbed away. This external damage exposes and compromises the reinforcement wires, which then give way, leading to a high-pressure leak or a full rupture at the point of wear.

- Heat-Related Blowout: A blowout caused by high temperatures is often accompanied by signs of heat aging, such as a hardened, brittle, or cracked outer cover. The heat degrades the hose material from the inside out, weakening its structure until it can no longer contain the pressure.

- Fitting Failure Blowout: Sometimes, the hose itself is not the problem. A blowout can occur when the hose separates from its fitting, often due to improper crimping, a faulty fitting, or a significant pressure surge that dislodges the connection. The result is a complete separation of the hose from the fitting.

- Kinking-Induced Blowout: A blowout caused by kinking or a bend radius that is too tight will show a pinched or flattened area. The kinking concentrates stress and fluid pressure at that single point, causing the reinforcement to fail prematurely, even if the system pressure is within the hose’s limits.

Preventing Hydraulic Hose Blowouts

Preventing a hydraulic hose blowout is a proactive process that requires regular attention and adherence to best practices. Since hoses are the most vulnerable components in a hydraulic system, a robust maintenance and inspection routine is the most effective defense against catastrophic failure. It is far more cost-effective to prevent a blowout than to deal with the resulting downtime, cleanup, and potential injuries.

The key to prevention lies in selecting the right components and ensuring they are installed, used, and maintained correctly throughout their service life.

Proactive Replacement: Even with perfect maintenance, all hydraulic hoses have a finite service life. Establish a proactive replacement schedule based on the equipment manufacturer’s recommendations or a set number of operating hours to replace hoses before they have a chance to fail.

Routine Visual Inspections: Regularly inspect all hydraulic hoses for signs of wear and tear, such as abrasion, cracks, blistering, or leaks. Pay special attention to areas where hoses rub against other components or are exposed to sharp edges.

Use the Right Components: Always select a hydraulic hose with the correct pressure rating, temperature tolerance, and fluid compatibility for your specific application. Using a hose that is underrated for the system’s pressure or fluid type is a direct path to failure.

Proper Routing and Installation: Ensure that hoses are routed correctly without any twisting, kinking, or tight bends that exceed the minimum bend radius. Use clamps, guards, or protective sleeves to prevent abrasion and keep hoses away from heat sources and moving parts.

Monitor System Pressure: Regularly check the system’s pressure gauges to ensure it is operating within the specified limits. Unexpected pressure spikes or a consistently high pressure can indicate a system problem that will put undue stress on your hoses.

Dealing with Hydraulic Hose Blowouts

Dealing with a hydraulic hose blowout requires immediate and careful action to ensure safety and minimize damage. A blowout is a major safety event due to the potential for injury from high-pressure fluid, as well as the risk of fire and environmental contamination. The first priority is always to secure the area and protect personnel.

After that, a systematic process for cleanup and repair can begin, ensuring that the machine is returned to a safe operating condition as quickly as possible.

- Cleanup and Disposal: After the repair, thoroughly clean up the spilled hydraulic fluid and dispose of all contaminated materials, including the old hydraulic hose, following local environmental regulations.

- Immediate Safety First: Immediately shut down all equipment and systems. Do not approach the machine until the engine is off and you are certain there is no pressure in the lines. Evacuate all personnel from the area to prevent injury from fluid spray, which can be difficult to see.

- Contain the Spill: Once the area is secure, take steps to contain the hydraulic fluid spill. Use absorbent materials, like pads or granules, to soak up the fluid and prevent it from spreading. This is crucial for environmental protection and to prevent slip hazards.

- Assess the Damage: Carefully inspect the failed hydraulic hose to determine the cause of the blowout. Look for signs of abrasion, a kink, a bulge, or other damage. This assessment is vital for preventing the same failure from happening again.

- Proper Repair: Do not attempt a quick or temporary patch. The only safe and effective solution is a complete hydraulic hose replacement. A qualified technician should select a new hydraulic hose with the correct pressure rating, length, and fittings, and install it according to manufacturer standards.

How to Fix a Blown Out Hose?

A blown-out hydraulic hose is a serious issue that requires immediate attention and a proper repair. Simply patching the hose is not an option due to the high pressures involved. A safe and permanent solution requires a full replacement of the damaged hose and its fittings.

Step 1: Secure the Area and Depressurize the System

Immediately shut down all equipment and clear the area of any personnel. Never approach a blown-out hose until you are certain all hydraulic pressure has been released. This is the most critical step to prevent severe injury from pressurized fluid.

Even after shutting down the machine, residual pressure may remain. Carefully follow the manufacturer’s manual to bleed off any trapped pressure by actuating the hydraulic controls until the system is completely inert.

Step 2: Contain the Spilled Fluid

Once the area is secure, take immediate action to contain the hydraulic fluid spill. Place absorbent pads or granules on the fluid to prevent it from spreading further, which can create a serious slip hazard and cause environmental damage.

Proper containment is essential for safety and environmental protection. Collect all contaminated materials and dispose of them in accordance with local regulations, ensuring a clean and safe work area for the repair.

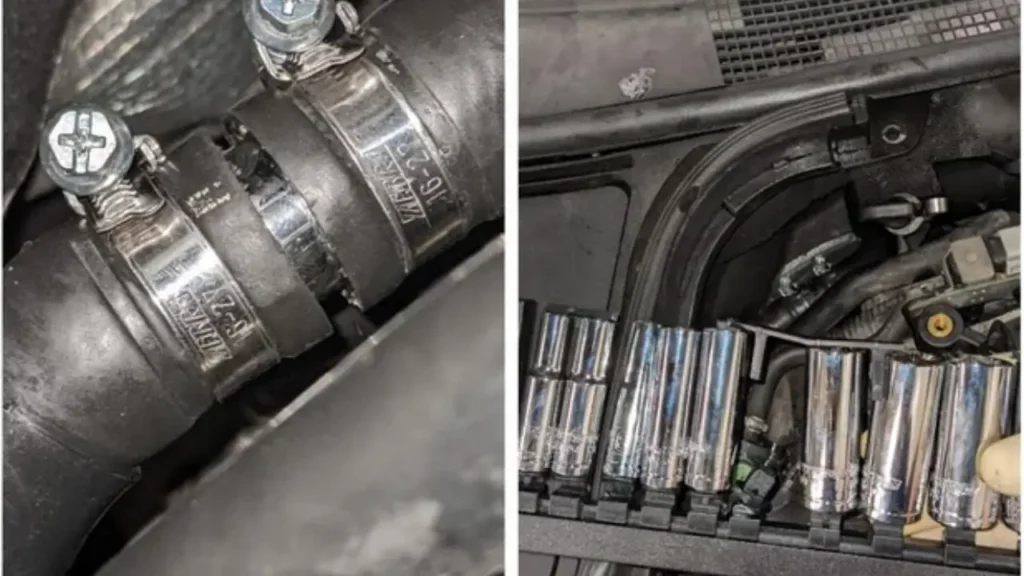

Step 3: Remove the Damaged Hose Assembly

Carefully locate and remove the blown-out hose. Use a pan to catch any remaining fluid as you loosen the fittings. Pay close attention to how the old hose was routed, and measure its exact length and fitting orientation for the replacement.

Remove the old hose completely, as it cannot be repaired. A hydraulic hose that has burst has compromised its internal structure, and attempting to reuse it or just replace the end is highly dangerous and can lead to another failure.

Step 4: Install a New Hydraulic Hose

Align the new hydraulic hose and carefully hand-thread the fittings into their ports to prevent cross-threading. Once snug, use a torque wrench to tighten the fittings to the manufacturer’s specifications, ensuring a secure, leak-free connection.

After installation, inspect the routing to ensure there are no kinks or twists. A correctly installed hose will have a much longer lifespan and prevent future failures, which is key to maintaining system reliability.

Step 5: Test the Repaired System

Start the machine and slowly build up pressure in the new hydraulic hose. Carefully check the fittings and the length of the hose for any leaks. Look for a fine mist or any wetness that indicates a faulty seal.

If a leak is found, immediately shut down the machine and re-tighten the fittings before re-testing. Only when you are confident there are no leaks should you return the machine to full operation.

Conclusion

Understanding the causes of a hydraulic hose blowout is the first step toward prevention. By paying close attention to factors like pressure ratings, abrasion, and proper installation, you can significantly reduce the risk of a catastrophic failure. Proactive maintenance and regular inspections are your best defense against unexpected downtime and potential safety hazards, ensuring your equipment operates reliably.

Ignoring the signs of a failing hose is a risk no one should take. A simple, affordable repair can prevent a costly blowout that could damage machinery, injure workers, and lead to significant cleanup expenses. Implementing a robust maintenance schedule and training staff on proper hose handling and inspection is a wise investment in the longevity and safety of your operations.

For all your hydraulic hose needs, remember that quality is paramount. We invite you to explore our comprehensive range of dependable hydraulic hoses. You can get wholesale hydraulic hoses from Kingdaflex, ensuring you receive the best in performance, durability, and value for your business.

Can hydraulic hoses be repaired once they blow out?

It’s generally safer and more effective to replace a blown-out hydraulic hose rather than attempting repairs, as the integrity of the hose may be compromised.

How often should hydraulic hoses be inspected?

Regular inspections should be conducted according to the manufacturer’s recommendations, but a general rule of thumb is to inspect hoses every 500 hours of operation.

Can using a higher-rated hydraulic hose prevent blowouts

While using a higher-rated hose may provide additional safety margin, it’s crucial to ensure that all components in the hydraulic system are compatible and rated accordingly.

Are hydraulic hose blowouts preventable through maintenance alone?

While maintenance plays a vital role in prevention, other factors like proper installation, pressure control, and hose protection measures are equally important.

What should I do if a hydraulic hose blowout causes fluid leakage?

In case of fluid leakage, contain the spill using appropriate materials and follow environmental safety procedures to minimize damage.