Hydraulic systems play a crucial role in various industries, and at the heart of these systems are hydraulic hoses.

The proper functioning of these hoses is essential for the efficiency and safety of hydraulic machinery.

In this article, we will delve into the intricate world of hydraulic hose fabrication, exploring the processes, challenges, advancements, and the critical role it plays in maintaining a robust hydraulic infrastructure.

Understanding Hydraulic Hoses

Hydraulic hoses are the unsung heroes in the world of machinery, transmitting power and ensuring the seamless operation of hydraulic systems. They come in various types, each designed for specific applications, ranging from high-pressure industrial settings to mobile machinery. Understanding the basics of hydraulic hoses is the first step in appreciating the significance of their fabrication.

Hydraulic Hose Fabrication Process

The fabrication process for hydraulic hoses involves several key steps to ensure the creation of reliable and durable components for hydraulic systems. Here is an overview of the typical fabrication process:

Material Selection:

The process begins with the careful selection of materials. High-quality materials, such as synthetic rubber for the inner tube and high-tensile steel or textile reinforcement for strength, are chosen based on the specific requirements of the hydraulic system.

Cutting and Preparing Components:

The selected materials are then cut and prepared according to the desired hose specifications. This includes cutting the inner tube, reinforcement layers, and outer cover to the required lengths and shapes.

Assembly:

The various components are assembled in a precise order. The inner tube is typically placed first, followed by the reinforcement layers, which provide strength and flexibility, and finally, the outer cover for protection against environmental factors.

Crimping:

Crimping involves attaching the end fittings securely to the hose. The crimping process uses a hydraulic crimper to compress and deform the metal fitting, creating a tight and reliable seal between the hose and the fittings.

Quality Control:

Rigorous quality control measures are implemented throughout the fabrication process. This includes inspections of the materials, measurements, and testing of the assembled hoses to ensure they meet industry standards and specifications.

Testing:

Hydraulic hoses undergo various tests to verify their performance and reliability. Common tests include pressure testing to assess the hose’s ability to withstand different pressure levels, leak testing to ensure proper sealing, and impulse testing to evaluate the hose’s durability under repeated pressure fluctuations.

Marking and Identification:

Each fabricated hydraulic hose is marked with essential information such as size, pressure rating, and manufacturer details. This helps in proper installation and maintenance.

Packaging:

The final step involves packaging the fabricated hoses for shipment, ensuring they reach the end-users in optimal condition.

Throughout the fabrication process, attention to detail, precision, and adherence to industry standards are critical to producing hydraulic hoses that serve as reliable components within hydraulic systems, effectively transmitting fluid power while withstanding various operational conditions.

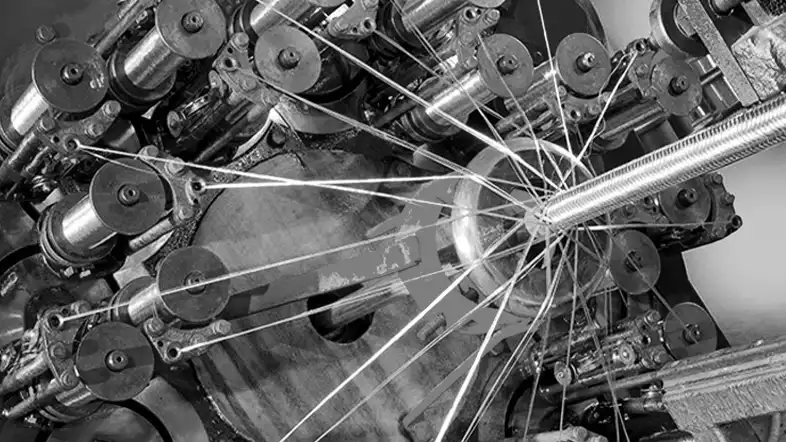

Hydraulic Hose Fabrication Equipment

Hydraulic hose fabrication equipment refers to the machinery and tools used in the process of creating hydraulic hoses. Hydraulic hoses are essential components in hydraulic systems, transmitting fluid power to operate machinery and equipment.

Fabricating these hoses involves assembling various components to create a durable and reliable product capable of withstanding high pressure and demanding operating conditions.

Here are key components and aspects of hydraulic hose fabrication equipment:

Hydraulic Hose Crimping Machines:

Function: A hydraulic hose crimping machine is crucial for attaching fittings to the ends of hydraulic hoses. The crimping process involves compressing the fitting onto the hose using high pressure, creating a secure and leak-proof connection.

Types: There are different types of crimping machines, including manual, electric, and hydraulic models. The choice depends on the volume of hose fabrication and the desired level of automation.

Cutting Machines:

Function: Hydraulic hoses often need to be cut to specific lengths. Cutting machines are used to achieve clean and precise cuts, ensuring that hoses are the correct size for the application.

Varieties: Cutting machines can be manual, semi-automatic, or fully automatic, with some capable of handling multiple hoses simultaneously.

Skiving Machines:

Function: Hydraulic hose skiving is the process of removing the outer layer of a hydraulic hose before attaching the fitting. Skiving machines are used for this purpose, creating a smooth surface for the fitting to be securely attached.

Importance: Skiving enhances the integrity of the hose assembly, ensuring a proper fit and preventing leaks.

Cleaning Equipment:

Function: Before hoses are assembled, it is crucial to clean the hydraulic hoses thoroughly to remove contaminants. Cleaning equipment, such as brushes and air or fluid flush systems, is used to achieve a clean and debris-free surface.

Importance: Clean hoses reduce the risk of system contamination and ensure optimal performance.

Marking Machines:

Function: Marking machines are used to label hoses with essential information, including specifications, date of manufacture, and other relevant details. It is important to make hydraulic hose labels to classify them in the hydraulic hose warehouse.

Compliance: Proper marking helps in compliance with industry standards and facilitates easy identification and maintenance.

Testing Equipment: Hydraulic Hose Testing: The Ultimate Guide to Newbie 2023

Function: Hydraulic hoses must undergo testing to ensure they meet specified performance standards. Testing equipment, such as pressure testing machines, checks the hoses for leaks, durability, and pressure resistance.

Quality Assurance: Comprehensive testing ensures that fabricated hoses are reliable and safe for use in various hydraulic applications.

Assembly Workstations:

Layout: Fabrication often involves assembly workstations where operators can efficiently cut, crimp, skive, and assemble hoses.

Organization: Well-designed workstations contribute to an organized and efficient manufacturing process.

The use of advanced hydraulic hose fabrication equipment is critical in ensuring the production of high-quality hoses that meet industry standards and specific application requirements. The equipment used may vary based on the scale of production, the type of hoses being manufactured, and the level of automation desired by the fabricator.

DIY Hydraulic Hose Fabrication Tips

Fabricating hydraulic hoses yourself can be a cost-effective and convenient solution, especially for specific or unique applications. However, it’s crucial to follow proper guidelines to ensure safety, functionality, and reliability. Here are some DIY hydraulic hose fabrication tips:

Understand Your Requirements:

Identify the specifications and requirements of the hydraulic hose you need. Consider factors such as pressure rating, hose diameter, length, and compatibility with hydraulic fluids.

Select High-Quality Components:

Choose quality materials for your DIY project. Opt for a high-quality inner tube material (such as synthetic rubber), appropriate reinforcement layers (steel or textile), and a durable outer cover. Quality components contribute to the overall reliability of the hose.

Use the Right Tools:

Invest in proper tools for cutting, crimping, and assembling hydraulic hoses. A hydraulic hose crimper is a key tool for attaching end fittings securely. Ensure that the tools are suitable for the hose size and type you are working with.

Follow Manufacturer Guidelines:

Adhere to the guidelines and specifications provided by the hydraulic hose and fitting manufacturers. This includes information on recommended assembly procedures, crimping specifications, and any specific considerations for the materials used.

Measure and Cut Precisely:

Accurate measurements are crucial for a successful hydraulic hose assembly. Use appropriate measuring tools, and make clean and precise cuts to achieve the desired hose length.

Proper Assembly Sequence:

Follow the correct assembly sequence, starting with the inner tube, followed by the reinforcement layers, and finishing with the outer cover. Ensure that each component is properly aligned and securely connected.

Cleanliness is Key:

Maintain a clean working environment to prevent contaminants from entering the hydraulic system. Clean the hose ends, fittings, and assembly tools thoroughly before starting the fabrication process.

Check for Compatibility:

Ensure compatibility between the hose and the hydraulic fluid to be used. Different hydraulic fluids may require specific hose materials to prevent degradation or damage.

Test the Assembly:

After assembling the hydraulic hose, conduct a pressure test to check for leaks and confirm the assembly’s integrity. Follow safety precautions during the testing process.

Properly Install and Secure:

Install the fabricated hydraulic hose carefully, following the equipment manufacturer’s guidelines. Use appropriate clamps and brackets to secure the hose in place, preventing unnecessary stress or movement.

Regular Inspection and Maintenance:

Periodically inspect the DIY hydraulic hose for wear, damage, or leaks. Replace any components that show signs of wear, and perform regular maintenance to ensure optimal performance.

It’s important to note that while DIY hydraulic hose fabrication is possible, there are professional hose fabrication services available that can ensure compliance with industry standards and provide certified assemblies. If you are unsure or working on critical applications, consulting with a professional or seeking guidance from the hose and fitting manufacturers is recommended. Additionally, always prioritize safety and follow proper procedures to avoid accidents and system failures.

Environmental Considerations

As the world becomes increasingly focused on sustainability, the hydraulic industry is not exempt. This section explores environmentally friendly practices in hydraulic hose fabrication and the proper disposal of waste materials, ensuring a responsible approach to manufacturing.

Importance of Regular Maintenance

Fabrication is only the beginning; regular maintenance is crucial to extending the lifespan of hydraulic hoses. This section will delve into the importance of routine checks, identifying signs of wear and tear, and addressing issues promptly to prevent system failures.

Choosing the Right Fabrication Partner

For businesses outsourcing their hydraulic hose fabrication, selecting the right partner is key. Factors to consider, questions to ask potential partners and the criteria for a reliable fabrication service will be explored.

Safety Precautions During Fabrication

Lastly, safety should always be a top priority during the fabrication process. This section will outline the necessary protective gear, safety measures, and the importance of ongoing training for fabricators to prevent accidents and ensure a secure working environment.

Conclusion

In conclusion, hydraulic hose fabrication is a critical aspect of maintaining a robust hydraulic infrastructure. From understanding the basics to exploring future trends, this article has provided a comprehensive overview of the intricacies involved in crafting the lifeline of hydraulic systems. By emphasizing quality, safety, and advancements, we ensure the seamless operation of machinery across various industries.

FAQs

Can I fabricate hydraulic hoses on my own?

While DIY is possible, professional fabrication ensures safety and reliability.

How often should hydraulic hoses undergo maintenance?

Regular checks are recommended, with frequency depending on usage and environmental conditions.

What materials are commonly used in hydraulic hose fabrication?

Common materials include rubber, thermoplastics, and metal for reinforcement.

Are there eco-friendly practices in hydraulic hose fabrication?

Yes, sustainable practices, such as using recyclable materials, are gaining traction in the industry.

What advancements can we expect in hydraulic hose fabrication?

Innovations in materials, manufacturing techniques, and IoT integration are on the horizon.