China is a leading manufacturer of hydraulic hose wraps, offering a wide variety of materials, sizes, and protective solutions. High-quality wraps help extend hose life, resist abrasion, and improve safety across industrial, construction, and automotive applications.

Wide Selection of Materials – We provide hydraulic hose wraps in materials like polyester, nylon, and PVC. Each material offers unique strength, flexibility, and heat or chemical resistance for specialized applications.

Custom Sizes Available – Hydraulic hose wraps can be tailored to match specific hose diameters, lengths, and thicknesses, ensuring a precise fit for optimal protection and performance.

Durability and Protection – Our wraps prevent hose wear, abrasion, and environmental damage, extending the life of hydraulic hoses while maintaining reliable performance under high-pressure conditions.

Cost-Effective Solutions – Buying hydraulic hose wraps from China offers competitive pricing without compromising quality, allowing businesses to reduce maintenance costs while ensuring long-term hose reliability.

Fast and Reliable Supply – With streamlined production and logistics, we can provide timely shipments of hydraulic hose wraps to support industrial and construction projects worldwide.

As a leading hydraulic hose wrap manufacturer from China, Kingdaflex provides a wide range of protective solutions for industrial, automotive, and construction applications. Our durable wraps resist abrasion, heat, and wear, ensuring long-lasting hose performance. With customizable sizes and materials, we deliver reliable, cost-effective products tailored to your specific hydraulic hose protection needs.

Abrasion Protection – Hose wraps prevent external damage caused by friction, rubbing, or contact with sharp surfaces, significantly extending hose service life and reducing maintenance costs.

Heat Resistance – Premium wraps protect hoses from high temperatures generated by machinery or environmental exposure, maintaining performance and preventing damage due to heat-related wear.

Chemical and Oil Resistance – Certain hose wraps shield hydraulic hoses from oils, chemicals, and corrosive substances, ensuring reliability in industrial and automotive applications.

Enhanced Safety – Protective wraps reduce the risk of hose failure, leakage, or bursts, safeguarding operators, equipment, and surrounding work areas.

Cost Savings – By reducing hose damage and maintenance requirements, hydraulic hose wraps help businesses save money while ensuring continuous and efficient system performance.

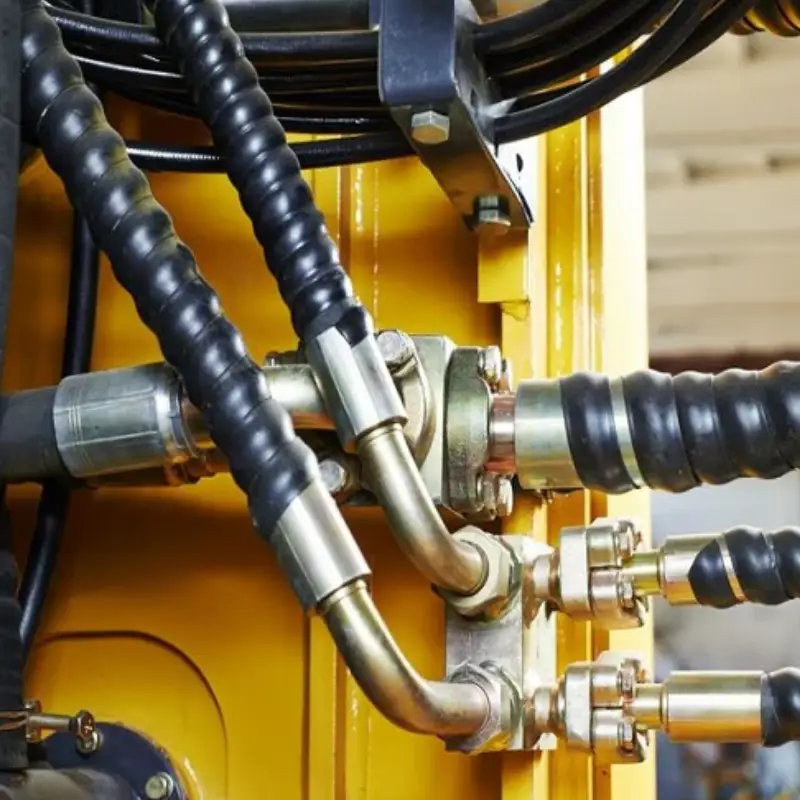

Construction Equipment – Hose wraps protect hydraulic hoses in excavators, loaders, and cranes from abrasion, debris, and environmental damage, ensuring safety and uninterrupted operation on construction sites.

Industrial Machinery – In manufacturing plants, hydraulic hose wraps prevent wear and tear from constant movement, friction, and chemical exposure, extending hose life and reducing maintenance costs.

Agricultural Equipment – Tractors, harvesters, and sprayers use hydraulic hose wraps to shield hoses from dirt, UV exposure, and mechanical stress, improving reliability and efficiency in farming operations.

Automotive and Transportation – Hydraulic hose wraps safeguard hoses in trucks, forklifts, and other vehicles, preventing damage from heat, vibration, and abrasion during daily operation.

Marine and Offshore Applications – Hydraulic hose wraps protect hoses from saltwater corrosion, UV damage, and physical wear, ensuring safe and durable hydraulic system performance in maritime environments.

Oil and Gas Industry – Hose wraps prevent abrasion, chemical exposure, and mechanical damage in pipelines, drilling rigs, and hydraulic equipment, enhancing safety and reducing downtime.

At Kingdaflex, we manufacture all types of hydraulic hose wraps to meet diverse industrial, automotive, and construction needs. Our durable wraps protect hoses from abrasion, heat, and mechanical damage, ensuring long-lasting performance. With customizable sizes and materials, we deliver reliable solutions tailored to your specific hydraulic hose protection requirements.

We provide colored hydraulic hose wraps in a variety of colors to meet identification and organizational needs. Our wraps help distinguish hoses for different applications, protect them from abrasion and wear, and improve safety in industrial, construction, and automotive environments. Available in multiple sizes, we supply solutions for diverse hydraulic systems.

We supply spiral hydraulic hose wraps designed to protect hoses from abrasion, wear, and mechanical damage. Ideal for industrial, automotive, and construction applications, these wraps provide flexibility and durability. Available in various sizes and materials, we offer solutions that help extend hose life and maintain reliable hydraulic system performance.

We provide Velcro hydraulic hose wrap for various industrial and automotive applications. Our Velcro wraps offer easy installation, secure fastening, and reliable protection against abrasion, heat, and mechanical wear. Available in different sizes and lengths, these wraps help organize, bundle, and safeguard hydraulic hoses, ensuring efficient performance and extended hose service life.

Hydraulic hose wraps play a vital role in protecting hoses, improving performance, and extending service life. Understanding their key aspects helps us deliver solutions tailored to industrial, automotive, and construction needs, ensuring safety, efficiency, and reliable operation across demanding applications.

We design hydraulic hose wraps to shield hoses from constant friction, rubbing, and mechanical damage. By preventing surface wear, we ensure that hoses maintain integrity and performance, reducing maintenance needs and extending the life of your hydraulic systems.

We select materials that withstand high temperatures, oils, and chemicals commonly found in industrial environments. Our wraps help hoses perform reliably under extreme conditions, preventing degradation and failures while ensuring consistent fluid transfer and safe hydraulic operations.

We create hose wraps that are flexible and easy to install, allowing for quick bundling and protection without compromising hose movement. This ensures convenient maintenance, reduces downtime, and maintains organized hydraulic systems across complex machinery and applications.

We offer hydraulic hose wraps in various sizes, lengths, and materials to meet specific application requirements. By providing customizable solutions, we ensure each hose is effectively protected and optimized for performance in diverse industrial and automotive environments.

Hydraulic hose wrap is a protective covering designed to shield hydraulic hoses from abrasion, heat, chemicals, and mechanical damage. It helps organize, bundle, and secure hoses while extending their service life. Commonly used in industrial, automotive, and construction applications, hose wraps ensure reliable hydraulic system performance and safety.

Hydraulic hose wraps are made from durable materials designed to protect hoses from abrasion, heat, and environmental damage. The choice of material depends on the application, providing flexibility, chemical resistance, and long-lasting performance for industrial, automotive, and construction hydraulic systems.

Polyester Fabric – Lightweight and flexible material that resists wear, ensuring hose protection and ease of installation.

Nylon Braiding – Strong synthetic fibers that provide excellent abrasion resistance and maintain hose integrity under pressure.

PVC Coating – Offers chemical, UV, and water resistance, enhancing hose durability in harsh environments.

Velcro Straps – Adjustable fastening system that bundles hoses securely and allows quick removal or reinstallation.

Rubber or Neoprene Sleeves – Flexible and durable covers that protect hoses from heat, oil, and mechanical damage.

Hydraulic hose wrap is designed to protect hoses and improve performance in demanding environments. It shields hoses from abrasion, heat, chemicals, and mechanical damage, ensuring longer service life, safety, and reliability in industrial, automotive, construction, and agricultural hydraulic systems.

Protecting Hoses from Abrasion – Hose wraps prevent friction and rubbing against surfaces or other components. By shielding the hose exterior, we reduce wear and tear, extend hose life, and maintain consistent hydraulic performance across high-pressure applications and rugged operational environments.

Heat and UV Protection – Hydraulic hose wraps provide insulation against high temperatures and UV exposure. We use materials that maintain hose flexibility, prevent degradation, and ensure reliable fluid transfer in environments with extreme sunlight, heat, or industrial machinery operation.

Chemical and Oil Resistance – Hose wraps protect hydraulic hoses from chemical spills, fuels, and oils. We select wraps that prevent corrosion and deterioration, safeguarding hoses and hydraulic systems while maintaining long-term operational efficiency and safety in chemical, automotive, or industrial applications.

Organization and Bundling – Hydraulic hose wraps help organize and bundle multiple hoses neatly. We offer wraps that secure hoses, reduce tangling, simplify maintenance, and improve workspace safety, ensuring hydraulic systems remain orderly, efficient, and easy to inspect or service.

Mechanical Damage Prevention – Hose wraps shield hoses from cuts, impacts, and abrasion caused by moving machinery. By installing wraps, we prevent hose punctures, leaks, and failures, enhancing safety and reducing downtime across industrial, construction, and agricultural hydraulic operations.

Hydraulic hose wraps come in several types, each designed to protect hoses under specific conditions. They vary in material, design, and fastening method, offering solutions for abrasion resistance, heat protection, chemical exposure, and mechanical safety across industrial, automotive, construction, and agricultural applications.

Polyester and Nylon Braided Wraps – These woven fabric wraps provide excellent abrasion resistance and flexibility. We use them to protect hoses from friction, wear, and movement, ensuring long-lasting performance in hydraulic systems exposed to mechanical stress and harsh operational environments.

PVC Coated Wraps – PVC-coated wraps offer chemical, UV, and water resistance. We supply these wraps for hoses operating in environments with exposure to oils, fuels, and sunlight, preventing degradation while maintaining hose integrity and hydraulic system efficiency.

Velcro Hose Wraps – Velcro wraps provide adjustable and reusable protection. We design them for easy bundling and organization of multiple hoses, allowing quick installation or removal while safeguarding hoses from abrasion and mechanical damage in industrial or automotive applications.

Rubber or Neoprene Sleeves – These flexible and durable sleeves protect hoses from heat, oil, and mechanical impacts. We recommend them for heavy-duty applications where hoses encounter extreme temperatures or potential puncture risks, ensuring safety and extended service life.

Spiral and Split Loom Wraps – Spiral or split loom wraps offer flexible, tubular protection around hoses. We use them to organize, bundle, and shield hoses from abrasion, tangling, and environmental hazards while maintaining hose mobility and easy maintenance access.

Installing hydraulic hose wraps correctly is essential for effective protection, hose longevity, and system safety. Proper installation ensures abrasion, heat, and chemical resistance while maintaining hose flexibility.

Following step-by-step procedures prevents damage, tangling, and downtime in industrial, automotive, construction, and agricultural hydraulic applications.

Measure and Cut the Wrap – We start by measuring the hose length accurately and cutting the wrap slightly longer than required. This ensures full coverage, overlaps if needed, and prevents exposed hose sections from abrasion or environmental damage during operation.

Position the Wrap on the Hose – We carefully slide or wrap the protective material over the hose, making sure it covers critical sections. Proper alignment avoids gaps, ensures consistent protection, and allows hoses to bend naturally without kinking or stressing the material.

Secure the Ends – We use Velcro, clamps, or adhesive tapes to secure the wrap ends. Proper fastening prevents slippage, maintains protection during movement or vibration, and ensures the hose wrap remains effective throughout the hydraulic system’s operational life.

Check for Obstructions – We inspect the hose after installation to ensure the wrap does not interfere with fittings, bends, or nearby components. This step prevents mechanical damage, tangling, and maintains smooth hydraulic fluid flow in the system.

Regular Maintenance and Inspection – We recommend periodic checks of the installed hose wraps. Observing wear, damage, or loosening allows timely adjustments, ensuring continuous hose protection and preventing costly failures or downtime in hydraulic operations.