When dealing with fluid transfer systems, understanding the different types of fittings is crucial for ensuring safety and preventing leaks. National Pipe Taper (NPT) and inverted flare fittings are two widely used, yet distinct, connection methods, each with specific applications and sealing principles.

This blog post will delve into the fundamental characteristics of NPT and inverted flare fittings, highlighting their unique designs, sealing mechanisms, and where you’ll typically find them. Knowing these differences is essential for anyone working with plumbing, automotive, or hydraulic systems to ensure proper selection and installation.

What are NPT Fittings?

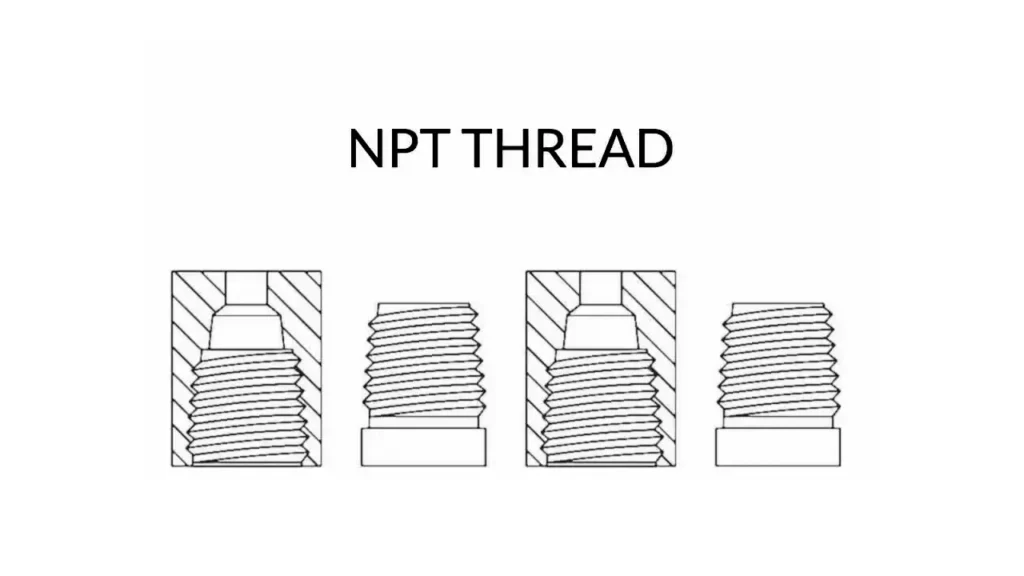

NPT, or National Pipe Taper, is a U.S. standard for tapered threads commonly found on pipes and fittings. These threads are designed to create a tight, leak-proof seal through metal-on-metal deformation as the male and female threads are tightened together.

The tapered design causes the threads to wedge, ensuring a secure connection for fluid and gas transfer, though thread sealants like Teflon tape or pipe dope are often used to ensure a completely leak-free joint.

What is Inverted Flare?

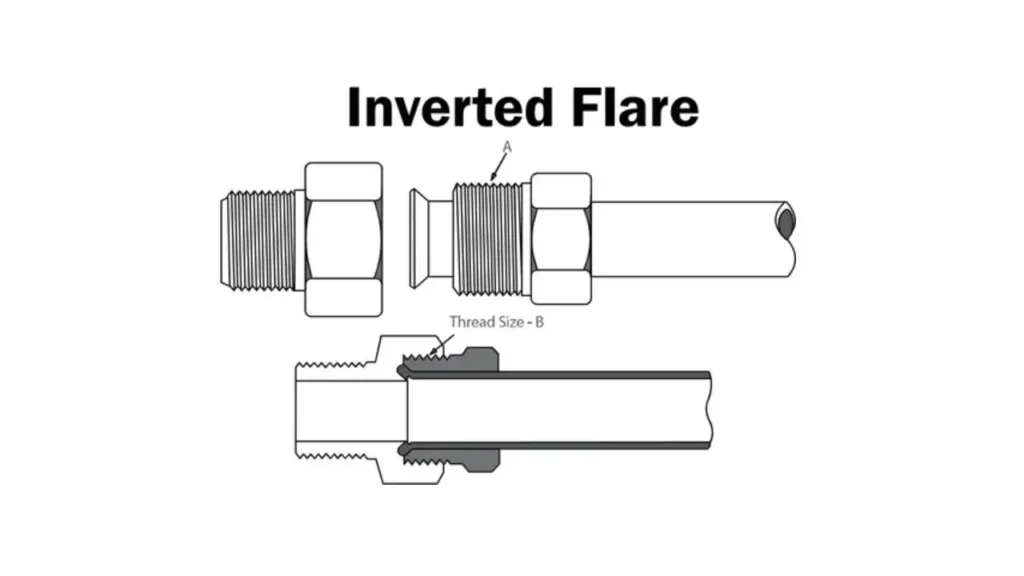

An inverted flare is a specific type of connection for tubing, widely used in automotive brake lines, fuel systems, and hydraulic applications. It’s characterized by the end of the tube being flared inward (or “inverted”) into a conical shape. This inverted cone then seats into a corresponding concave surface within the fitting.

When the flare nut is tightened, it compresses the flared tubing against the fitting’s seat, creating a secure, metal-on-metal, leak-resistant seal that is highly resistant to vibration and movement, making it ideal for dynamic environments.

NPT vs Inverted Flare

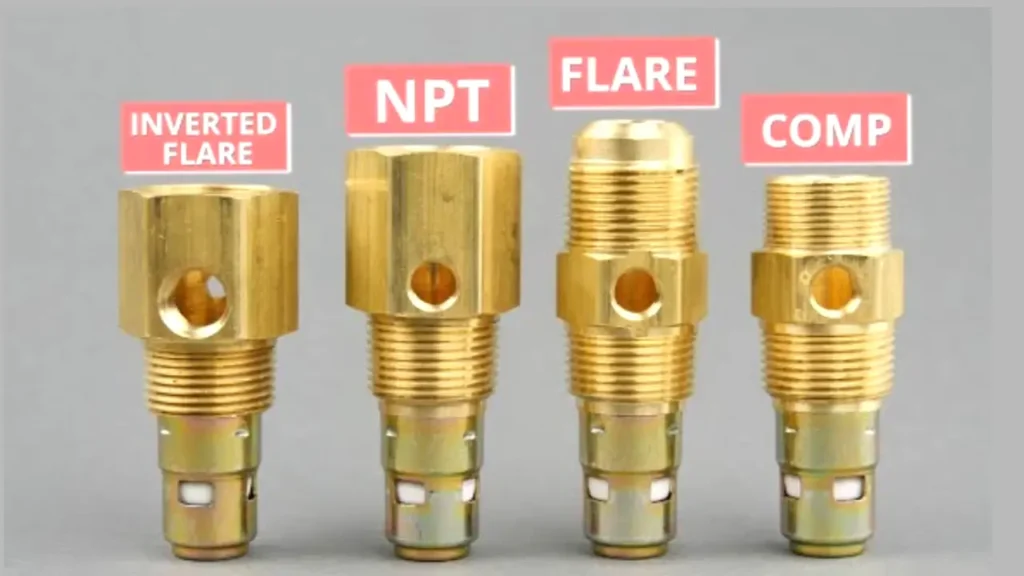

When connecting pipes or tubing, two common types of fittings are NPT (National Pipe Taper) and Inverted Flare. While both aim for leak-free connections, they achieve this through fundamentally different designs and are suited for distinct applications.

Sealing Mechanism

NPT fittings rely on a tapered thread design where the male and female threads gradually compress and wedge together as they are tightened. This metal-on-metal interference creates the seal. However, due to inherent imperfections in threading, thread sealants like PTFE tape or pipe dope are almost always required to fill any spiral leak paths and ensure a completely leak-proof connection, especially for gas or high-pressure fluids.

In contrast, inverted flare fittings achieve their seal through a mechanical compression of a flared tube end against a matching conical seat within the fitting. The tube itself is flared inward, and when the flare nut is tightened, it forces this flared surface directly against the fitting’s seat. This metal-on-metal contact creates a robust, vibration-resistant seal without the need for additional thread sealants.

Design and Form

NPT fittings feature external or internal threads that are tapered, meaning their diameter slightly decreases or increases along their length. This taper is standardized, typically at 1/16 inch per inch of length, which is what allows the wedging action to create the seal. The threads themselves have a 60-degree angle.

Inverted flare fittings consist of a fitting body with a concave conical seat and a corresponding flare nut that slides over the tubing. The tubing itself is flared to a specific angle (commonly 45 degrees in automotive applications) so that it perfectly mates with the conical seat inside the fitting. The threads on the flare nut and the fitting are straight, serving only to apply clamping force, not to seal.

Common Applications

NPT fittings are ubiquitous in general plumbing, industrial piping, and gas distribution systems. They are widely used for connecting rigid pipes in both residential and commercial settings for water, natural gas, steam, and compressed air, where a robust, permanent connection is desired. Their versatility in size and material makes them a standard for many threaded pipe connections.

Inverted flare fittings are predominantly found in automotive brake lines, fuel systems, and hydraulic applications where flexible tubing is connected. Their design makes them excellent at handling vibration and pressure fluctuations common in mobile machinery and vehicles. They are also seen in some refrigeration and HVAC systems for reliable, leak-free connections.

Installation Requirements

Installing NPT fittings generally involves applying thread sealant to the male threads, then hand-tightening the connection before using a wrench to achieve the final torque. Proper torque is essential to avoid over-tightening, which can damage the threads, or under-tightening, which can lead to leaks. Reusability can be an issue as the sealant often needs to be reapplied.

For inverted flare fittings, the tubing must first be prepared by cutting and deburring, then a flare nut is slid on, and the end of the tubing is flared using a specialized flaring tool. Once the flare is formed, the tube is inserted into the fitting, and the flare nut is tightened. No thread sealant is needed, and if the flare remains undamaged, these connections can often be reused multiple times.

Pressure Handling

NPT connections, when properly sealed with thread sealant, can handle a wide range of pressures. However, their reliance on sealant means that extreme pressure or temperature fluctuations can sometimes compromise the seal over time. Leakage can also be more difficult to detect if the sealant is preventing small seeps.

Inverted flare fittings are known for their excellent high-pressure capabilities due to the direct metal-on-metal seal. The compression of the flare against the seat creates a very robust and reliable connection that is less prone to leakage under high operating pressures and dynamic conditions, making them ideal for critical hydraulic and brake systems where failure is unacceptable.

| Feature | NPT (National Pipe Taper) | Inverted Flare |

| Sealing Mechanism | Tapered threads wedge, relies on sealant | Flared tube compresses against conical seat, metal-on-metal |

| Thread Type | Tapered threads | Straight threads (on nut), not for sealing |

| Sealing Material | Requires thread sealant (PTFE tape, pipe dope) | No sealant required |

| Common Applications | Plumbing, industrial piping, gas lines | Automotive brake/fuel lines, hydraulics, refrigeration |

| Reusability | Limited, often requires new sealant | Good, if flare is undamaged |

1/4 Inverted Flare vs 1/4 NPT

Focusing on 1/4 inch sizes, both 1/4 Inverted Flare and 1/4 NPT fittings are common in fluid transfer, but they serve different purposes due to their distinct designs and sealing principles. Understanding these differences is crucial for proper selection and installation.

Thread Specifications

For 1/4 NPT fittings, the “1/4” refers to the nominal pipe size, which doesn’t directly correspond to the actual thread diameter. A 1/4 NPT thread has a major outside diameter of approximately 0.540 inches (about 13.72 mm) and features 18 threads per inch with a 60-degree thread angle. The tapered design is essential for its sealing mechanism.

In contrast, a 1/4 Inverted Flare fitting refers to the outside diameter (OD) of the tubing it connects, which is precisely 1/4 inch. The threads on the flare nut are straight, typically 7/16″-24 UNF (Unified National Fine), and they do not create the seal. Instead, these threads are purely for applying the clamping force to compress the flared tube.

Sealing Method

1/4 NPT fittings create a seal by the wedging action of their tapered threads. As the male and female threads are tightened, they deform slightly, creating a metal-to-metal seal along the thread flanks. To ensure a leak-proof connection, particularly for gases or higher pressures, a thread sealant like PTFE tape or pipe dope is almost always required to fill any helical leak paths.

1/4 Inverted Flare fittings achieve a seal by compressing the 1/4-inch flared end of the tubing against a conical seat within the fitting body. The flare nut, sliding over the tubing, pushes the flared end into the seat. This metal-on-metal compression forms a tight, reliable seal that does not require any additional thread sealants, making it very effective for hydraulic and pneumatic lines.

Applications

1/4 NPT fittings are widely used in general plumbing, industrial process lines, and compressed air systems. Their commonality makes them a standard for connecting rigid pipes or components in applications where a robust, permanent connection is desired and the system can accommodate the use of thread sealants. Examples include connecting pressure gauges, valves, or pipe segments.

1/4 Inverted Flare fittings are a staple in automotive applications, particularly for brake lines, fuel lines, and transmission cooler lines, where 1/4 inch tubing is common. They are also found in some refrigeration systems. Their design offers excellent resistance to vibration and flexing, which is critical in vehicle environments, and the absence of sealants ensures no contamination of the fluid.

Installation Procedure

Installing a 1/4 NPT fitting involves applying thread sealant to the male threads, then hand-tightening, followed by wrench tightening to the recommended torque. Care must be taken not to overtighten, which can crack the fitting, or under-tighten, leading to leaks. Proper thread engagement and sealant application are key to a successful NPT connection.

For a 1/4 Inverted Flare connection, the 1/4-inch tubing must be precisely cut, deburred, and then flared using a specialized flaring tool. The flare nut is then slid over the tubing, and the flared end is seated into the fitting. Tightening the nut compresses the flare, requiring specific torque to ensure a proper seal without deforming the tubing.

Reusability and Maintenance

1/4 NPT connections are generally not designed for frequent disassembly and reassembly. Each time they are taken apart, the old thread sealant must be thoroughly removed, and new sealant applied, which can be time-consuming. Repeated assembly and disassembly can also wear down the tapered threads, potentially compromising the seal.

1/4 Inverted Flare connections are more forgiving regarding reusability. As long as the flared end of the tubing remains undamaged and the fitting’s seat is clean, the connection can be taken apart and reassembled multiple times without needing new sealants. This feature is advantageous in systems that require periodic maintenance or component replacement.

| Aspect | 1/4 NPT | 1/4 Inverted Flare |

| Nominal Size | Refers to pipe size, actual OD ~0.540″ | Refers to tubing OD, exactly 1/4″ |

| Sealing Mechanism | Tapered threads, requires sealant | Flared tube compresses against conical seat, no sealant |

| Thread Type | Tapered, 18 TPI, 60-degree angle | Straight, typically 7/16″-24 UNF (on nut) |

| Common Uses | General plumbing, industrial piping, compressed air | Automotive brake/fuel lines, hydraulics, refrigeration |

| Vibration Resist. | Moderate, can loosen if not properly sealed | High, robust for dynamic applications |

| Reusability | Limited, new sealant typically required | Good, if flare remains undamaged |

How to Choose NPT and Inverted Flare?

Choosing between NPT and Inverted Flare fittings hinges on several critical factors related to your specific application. The type of fluid, operating pressure, temperature range, and the need for disassembly are paramount considerations. NPT fittings are generally preferred for stationary, rigid piping systems handling various fluids, including gases, water, and steam, where a strong, permanent, and sealed connection is necessary.

- Fluid Type: Consider if the fluid requires an absolutely leak-proof seal without contaminants from sealants.

- Pressure & Temperature: Evaluate the maximum operating pressure and temperature. NPT can handle high pressures with proper sealing, while inverted flares excel in dynamic high-pressure applications.

- Vibration & Movement: If the system experiences significant vibration or movement, inverted flares offer superior resistance to fatigue and leakage.

- Disassembly Frequency: NPT connections, especially with sealant, are less ideal for frequent disassembly, whereas inverted flares are often designed for easier reassembly.

- System Material: The material of your tubing (e.g., steel, copper, nylon) will influence the feasibility of flaring and the strength of the flare.

Inverted flare fittings are the go-to choice for applications requiring extreme reliability under dynamic conditions, such as in vehicles. Their metal-on-metal seal offers inherent resistance to vibration and ensures a clean fluid path, free from thread sealant residues. Ultimately, understanding the unique strengths and limitations of each fitting type will guide you to the most appropriate and safest connection for your fluid transfer system.

Conclusion

Understanding the distinctions between NPT and Inverted Flare fittings is crucial for anyone working with fluid transfer systems, whether in automotive, industrial, or plumbing applications. Each offers unique advantages tailored to specific operational demands and pressure requirements.

By carefully considering the sealing mechanism, application environment, and necessary installation practices, you can ensure optimal performance and prevent costly leaks. Choosing the correct fitting type is paramount for safety and efficiency in any hydraulic or pneumatic system.

For reliable and high-quality solutions, consider Kingdaflex for your wholesale hydraulic fittings. Their extensive range ensures you’ll find the right NPT or Inverted Flare options to meet your project’s precise specifications and ensure a secure, long-lasting connection.