As your reliable PTFE hose manufacturer from China, we specialize in producing high-quality hoses designed for superior performance in demanding environments. Our PTFE hoses feature exceptional resistance to extreme temperatures, corrosive chemicals, and high pressure, ensuring durability and safety. With a non-stick inner surface, they provide excellent fluid transfer for critical applications in the chemical, food and beverage, and automotive industries.

Exceptional Chemical Resistance: Our hoses are compatible with a wide range of aggressive chemicals, solvents, and acids.

Wide Temperature Range: They perform reliably in extreme hot and cold conditions, from cryogenic temperatures to high-heat applications.

High-Pressure Durability: The reinforced braided construction allows our hoses to withstand significant working and burst pressures.

Non-Stick Interior: The smooth PTFE bore prevents material buildup, ensuring a consistent flow and easy cleaning.

Extensive Customization: We offer customized dimensions, braiding materials, and end fittings to meet your specific project needs.

Choose Kingdaflex for your wholesale PTFE hose needs. As a leading manufacturer with over 20 years of experience, we provide high-quality hoses known for their exceptional chemical and heat resistance. Our PTFE hoses are designed to ensure superior durability and a non-stick flow, making them the ideal choice for demanding industrial applications.

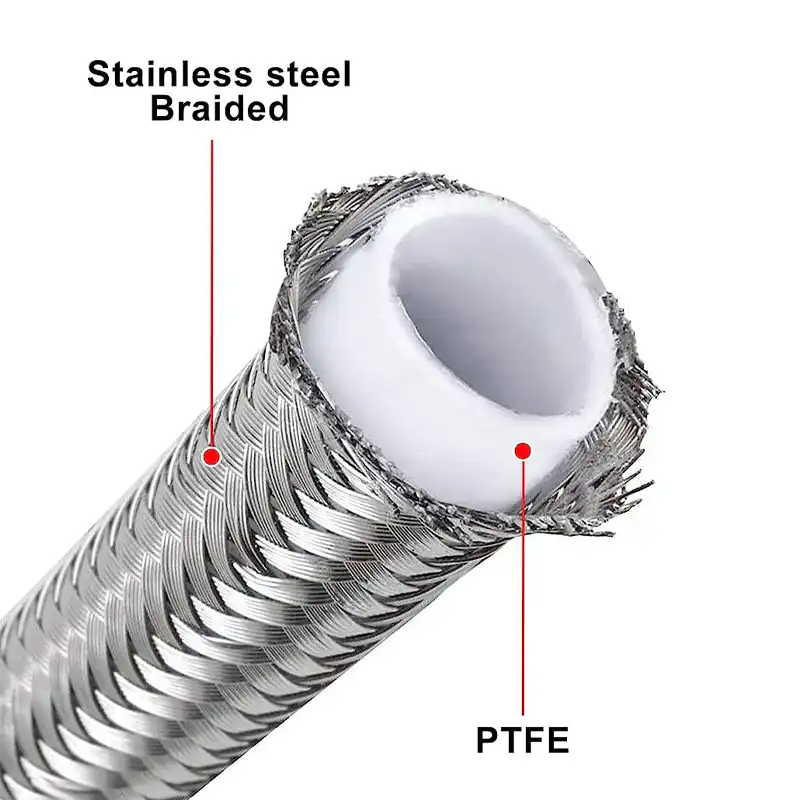

Inner Core (PTFE): The innermost layer is made of PTFE (Polytetrafluoroethylene). This material is chosen for its exceptional properties, including a wide temperature range, high chemical resistance, and a non-stick surface. The smooth, non-porous bore prevents material buildup and ensures a clean, consistent flow of fluids.

Outer Reinforcement (Stainless Steel): This layer provides the hose with its structural integrity and pressure resistance. It is a braided wire mesh, most commonly made of stainless steel. The braiding protects the delicate PTFE inner core from external damage and allows the hose to withstand very high working pressures, making it suitable for demanding industrial and automotive applications.

Chemical Transfer: They are extensively used for transporting aggressive chemicals, acids, and solvents in chemical plants and laboratories, where resistance to corrosion and chemical degradation is essential.

Automotive: In the automotive sector, they are used for high-performance applications like brake lines, fuel lines, and power steering lines, where they must withstand high pressure, extreme temperatures, and various fluids.

Food and Beverage: The non-stick and inert properties of PTFE make it a perfect choice for hygienic applications. It’s used for transferring food products, beverages, and pharmaceuticals where cleanliness and preventing contamination are paramount.

Aerospace: Due to their lightweight yet durable construction and ability to withstand extreme temperatures, PTFE hoses are used in aircraft fuel systems and hydraulic lines.

Pharmaceutical: They are used in pharmaceutical manufacturing for sterile fluid transfer and in other applications where a non-reactive and easy-to-clean surface is required to prevent cross-contamination.

Industrial Steam Transfer: The high-temperature resistance of PTFE makes these hoses suitable for low-pressure steam transfer in industrial settings.

As a leading PTFE hose manufacturer, we produce a comprehensive range of hoses designed for superior performance. Our PTFE hoses feature exceptional chemical, temperature, and pressure resistance, with a non-stick interior for clean fluid transfer. We offer a variety of sizes and fittings to provide a perfect solution for your specific industrial applications.

We offer premium PTFE fuel hoses, engineered for the demands of high-performance automotive and motorsport applications. Our hoses are built with a smooth-bore PTFE core for maximum flow and are reinforced with stainless steel braiding to handle extreme pressures and temperatures. This design ensures superior resistance to all types of fuel, including ethanol and methanol.

We offer premium stainless steel braided PTFE hoses, engineered for the most demanding applications. Our hoses feature a smooth PTFE core for superior chemical resistance and a non-stick flow, reinforced by a durable stainless steel braid that provides exceptional pressure and temperature resilience. This construction ensures a reliable, long-lasting solution for critical fluid transfer.

We offer specialized PTFE power steering hoses, engineered for high-performance applications. Our hoses are built to withstand the extreme pressures and high temperatures of modern power steering systems. Featuring a smooth, durable PTFE inner core and a robust stainless steel braid, our hoses provide superior fluid transfer and a long, reliable service life, eliminating leaks and ensuring peak performance.

When creating a PTFE hose solution, we focus on four key aspects to ensure the final product perfectly matches your application’s unique demands. Our customization process allows us to deliver a hose that not only fits but also provides optimal performance, safety, and durability in the most challenging environments.

We offer PTFE inner cores in both smooth bore and convoluted styles. The smooth bore provides excellent flow rates and easy cleaning, while the convoluted style offers superior flexibility for applications with tight bend radius requirements. We can also provide an anti-static carbon-impregnated liner for applications involving static-generating fluids.

We can customize the outer reinforcement layer to meet your pressure and environmental needs. Options include a single or double layer of braided stainless steel for high-pressure durability. For a lightweight, corrosion-resistant solution, we also offer braided synthetic fiber reinforcement. The braiding can be customized for specific strength requirements.

We offer a complete range of customizable dimensions, including the inner diameter and overall hose length. This precision ensures the hose provides the correct flow rate and fits perfectly in your assembly, preventing pressure loss and eliminating installation issues. We can tailor the size to match your exact specifications.

We provide a wide array of custom-machined end fittings and connections. These can be made from various materials, including stainless steel, carbon steel, and brass, to ensure chemical compatibility with your fluid media. We can supply standard crimped fittings, male or female NPT, JIC, or custom-designed connections.

The manufacturing of PTFE hose is a specialized process that combines precision extrusion with advanced braiding techniques to create a product with superior performance. The process is designed to ensure the PTFE core is uniform and flawless, while the reinforcement is strong and perfectly applied for maximum durability.

PTFE Extrusion: The process begins with extruding the PTFE resin into a seamless tube. This is a critical step that ensures the inner core is non-porous and has the correct dimensions.

Sintering: The extruded tube is then heated in an oven (sintering) to a specific temperature. This process solidifies the PTFE, making it strong, non-stick, and resistant to chemical attack.

Braiding: The sintered PTFE tube is then moved to a braiding machine. Here, stainless steel wire or textile fibers are tightly braided around the core. The number of braids and the tension are carefully controlled to achieve the desired pressure rating.

Final Sintering (Optional): Some manufacturers perform a final sintering after braiding to bond the reinforcement to the PTFE, enhancing the hose’s structural integrity and performance.

Cutting and Assembly: The completed hose is cut to the required length. Finally, end fittings are attached to the hose using specialized crimping equipment to create a complete, leak-proof hose assembly.

A PTFE hose is a type of industrial hose with an inner core made from PTFE (Polytetrafluoroethylene), a synthetic fluoropolymer commonly known by the brand name Teflon. This core is typically reinforced with an outer layer of braided stainless steel or synthetic fiber.

A PTFE hose is primarily used for transferring a wide variety of fluids, gases, and chemicals in applications where exceptional chemical resistance, a broad temperature range, and a non-stick surface are required. Its unique properties make it a superior choice over traditional rubber or plastic hoses in demanding environments.

Key Uses of PTFE Hoses:

Chemical Transfer: Transporting highly corrosive chemicals, acids, bases, and solvents in chemical plants, laboratories, and processing facilities. The inert nature of PTFE prevents the hose from degrading.

Automotive: Serving as high-performance lines for fuel, brake fluid, and power steering fluid. PTFE hoses can withstand the high pressures and temperatures of a vehicle’s engine bay and are compatible with various aggressive fluids.

Food and Beverage Processing: Used for transferring food products, beverages, and dairy. The non-porous and non-stick properties of PTFE prevent bacterial growth and cross-contamination, making it ideal for hygienic applications.

Pharmaceutical and Medical: Employed in the manufacturing of pharmaceuticals and for medical equipment where cleanliness and non-reactivity with sensitive media are critical.

Industrial Steam: The high-temperature rating of PTFE allows these hoses to be used for low-pressure steam transfer.

Aerospace: Used in aircraft hydraulic and fuel systems, where their lightweight construction, durability, and resistance to temperature extremes are essential for safety and performance.

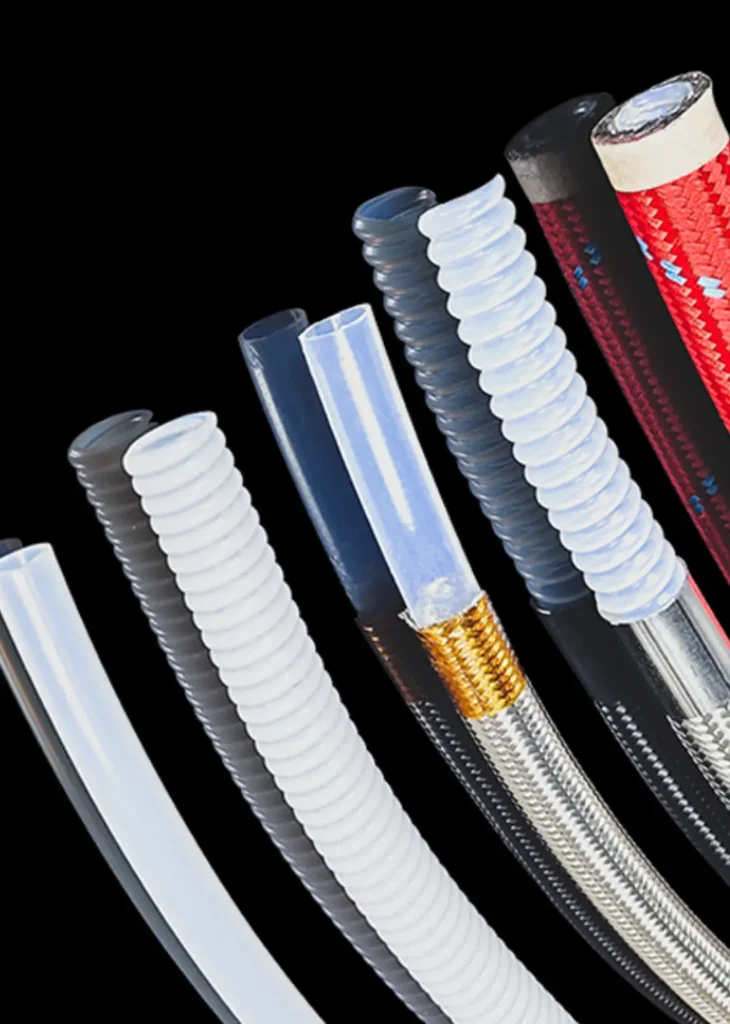

PTFE hoses come in several types, primarily distinguished by their core construction and reinforcement. The choice between these types depends on the specific application’s requirements for flexibility, pressure, flow rate, and resistance to static buildup.

Smooth Bore PTFE Hose: This is the most common type, featuring a smooth, uniform inner bore. It is ideal for applications requiring high flow rates and easy cleaning, such as in the food and beverage industry.

Convoluted PTFE Hose: This type has a corrugated or convoluted inner bore, which provides exceptional flexibility and a tighter bend radius. It is used in applications with limited space or where a high degree of movement is required, such as in robotic or hydraulic systems.

Anti-Static (Carbon-Lined) PTFE Hose: For applications involving the transfer of non-conductive fluids, this type has a black carbon-impregnated inner layer. This design dissipates static electricity that can build up from fluid friction, preventing sparks and potential explosions.

Stainless Steel Braided PTFE Hose: The most popular type, featuring an outer layer of braided stainless steel. This reinforcement provides high pressure ratings and physical protection, making it suitable for demanding industrial and automotive applications.

Textile Braided PTFE Hose: This type uses a textile braid for reinforcement instead of stainless steel. It is lighter and more flexible than its metal-braided counterpart and is often used in applications that do not require extremely high pressures.