The hydraulic hose plays an important role in the construction field, and today I am happy to share with you the hydraulic hose manufacturing process here, how to manufacture hydraulic hose step by step in our hydraulic hose manufacturer.

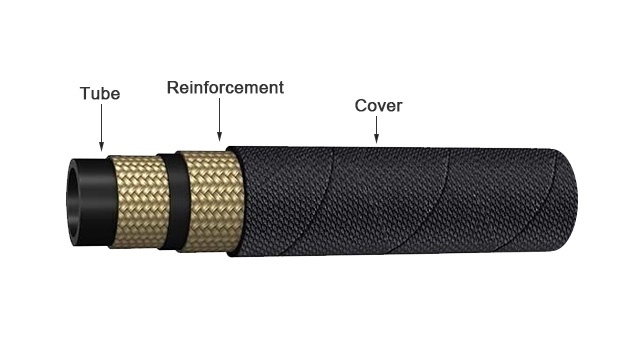

How is a hydraulic hose manufactured? You got to know the hydraulic hose structure and a hydraulic hose pipe has three parts, including an inner tube, reinforcement, and outer cover.

We can manufacture the hydraulic hose following its structure, to create a hydraulic hose inner tube, and then reinforcement, and finally outer cover.

So now drive into the part of the hydraulic hose fabrication, to get full about making hydraulic hose, step by step.

Here are go!

Prepare Raw Materials (Synthetic Rubber and Stainless Steel Wire)

At the very beginning of the hydraulic hose manufacturing process, we need to prepare all of the raw materials ahead of time, and here is the synthetic rubber material and stainless steel wire.

You guys can click here to know what hydraulic hose is made of. We will prepare enough raw material rubber in our hydraulic hose manufacturer workshop.

Here is a video showing the rubber compounding process to prepare for manufacturing hydraulic hoses.

Synthetic rubber material

You can see the rubber pieces lying here, get ready to manufacture the inner tube of the hydraulic hose. We use the Banbury rubber mixing machine to mix the rubber material, to make the rubber become the raw material for making the hydraulic inner tube.

Stainless steel wire

At the same time, we also need to prepare the stainless steel wire to get ready for manufacturing the reinforcement of the hydraulic hose.

Here is the stainless steel wire as the raw material to manufacture the reinforcement layer for hydraulic hoses. We source the very long stainless steel wire, up to 50k meters in a roll, to prepare the next step.

And then we need to twist some stainless steel wire together to combine a thick stainless steel wire. The reinforcement of the hydraulic hose is designed to add much more strength to the whole hydraulic hose pipe, to work well under high pressure.

The more stainless steel wire can make the hydraulic hose much stronger. Regularly, our manufacturer can combine 7-8 stainless steel wires into one, of course, we can twist the stainless steel wire according to your requirements. Then we will roll the combined stainless steel to the stainless steel cylinder tube.

Extrude the Synthetic Rubber to Create Inner Tube

Now is the time to manufacture the inner tube of the hydraulic hose. We use the rubber extruder machine to extrude the rubber material to create the inner tube.

Here is a steel rod in the rubber extruder machine, to squeeze out the empty rubber tube. And the diameter of the steel rod equals the inner diameter (I.D) of the finished hydraulic hose.

We will get the inner tube of the hydraulic hose after extruding process, and the inner tube has a smooth surface, looking shining.

Rubber extrusion is a manufacturing process used to create rubber hydraulic hoses in continuous lengths. It involves forcing a rubber compound through a die of a specific shape under high pressure.

Hydraulic hoses are a common product made through rubber extrusion. They are essential components in various industries, from construction and agriculture to manufacturing and mining.

PP Stick Is Used for Hydraulic Hose Inner Tube Extrusion

A PP stick, also known as a soft core or mandrel, is a crucial component in the manufacturing of hydraulic hoses. It’s a long, slender rod made of polypropylene plastic that serves as a temporary core during the extrusion process.

Here’s how a PP stick is used in hydraulic hose extrusion:

- Shape Retention: The PP stick provides a stable, cylindrical form around which the rubber or thermoplastic hose material is extruded. This ensures the hose maintains its desired diameter and shape throughout the manufacturing process.

- Smooth Inner Surface: The smooth surface of the PP stick transfers to the inner surface of the hose, resulting in a smooth bore. This minimizes friction and improves fluid flow within the hose.

- Easy Extraction: After the hose is cured, the flexible PP stick can be easily removed, often through mechanical or hydraulic means. This minimizes the risk of damaging the hose during the extraction process.

By using PP sticks as mandrels, hydraulic hose manufacturers can produce high-quality hydraulic hoses with consistent dimensions, smooth inner surfaces, and optimal performance.

Manufacture Reinforcement Layer

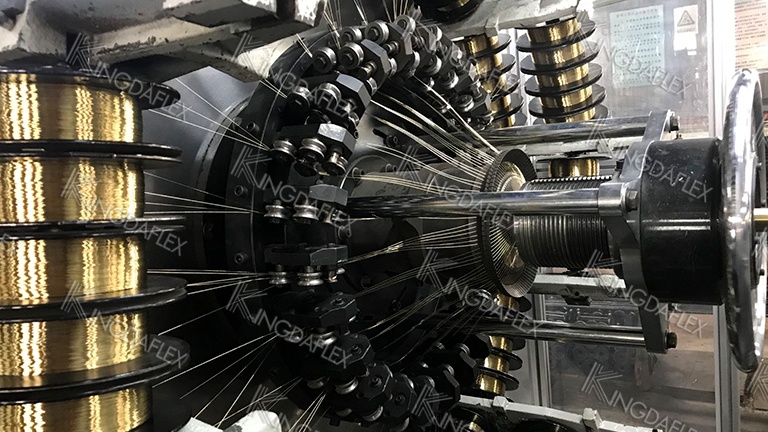

Now we prepare the stainless steel wire to create the reinforcement layer of the hydraulic hose. Here are 2 different methods to manufacture the stainless steel reinforcement, so here are 2 types of hydraulic hose we can manufacture in this step, braided hydraulic hose and spiral hydraulic hose.

Braided hydraulic hose

We use the hydraulic hose braiding machine to create the braided reinforcement, to get the braided hydraulic hose.

Here is the video showing you how the braided hydraulic hose is manufactured by the hydraulic hose braiding machine.

And then we will get the semi-finished hydraulic hose with braided reinforcement.

The braided hydraulic hose reinforcement looks like the gold hair braids.

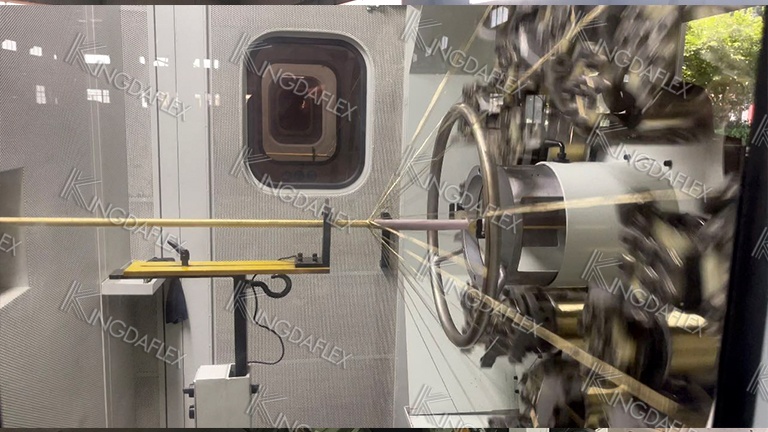

Spiral hydraulic hose

The machine used to manufacture the spiral hydraulic hose is different, and this is the 4-wire spiraling machine for braiding hydraulic hose.

And you guys can see the difference between braided vs spiral hydraulic hoses. and how spiral hydraulic hose is manufactured in this short video.

This is the manufacturing process to make the spiral hydraulic hose in the workshop.

Then we get the finished spiral hydraulic hose reinforcement.

You guys can see the comparison of braided hydraulic hose and spiral hydraulic hose.

Extrude Outer Rubber Cover

And then we need to extrude the rubber to create the outer cover to parcel the reinforcement layer, and this is the third layer of the hydraulic hose, also the last layer.

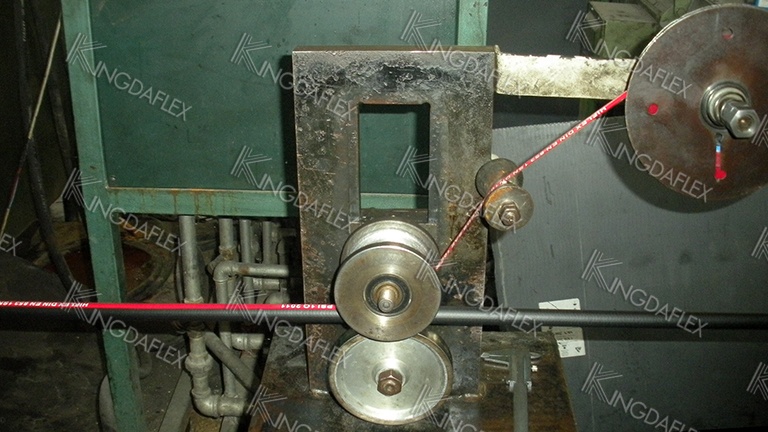

Print Private Label

In this step, we can customize your private label or your hose company logo on the surface of the outer cover of the hydraulic hose. All of the hydraulic hose specifications and your brand name will be printed on the surface of the hydraulic hose layline.

You can read the basic parameter information from the finished hydraulic hose, and we can print anything you want, such as private label, company logo, hydraulic hose specifications and etc. And at the moment, the hydraulic hose is manufactured with a smooth surface, without any texture.

Create Surface Texture

Next, we can create the texture to make the hydraulic hose cover surface look special, and we use the press cloth to create your desired texture on the hydraulic hose surface, by adding much pressure to the hydraulic hose surface. The rubber material is soft, so the press cloth will leave the designed texture on the surface.

Vulcanize Hydraulic Hose

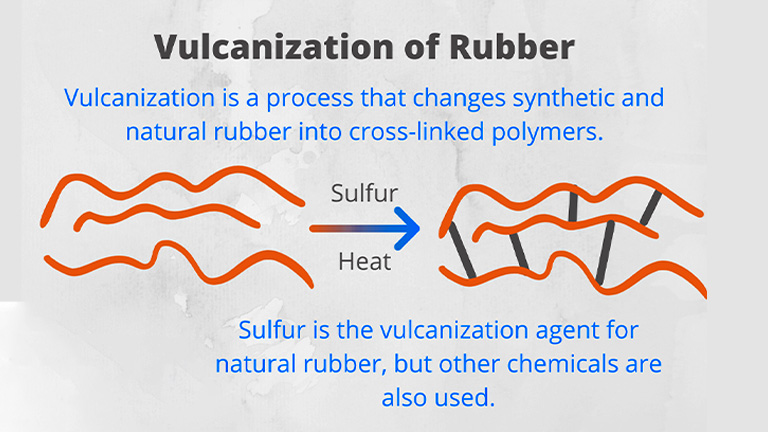

Then we need to vulcanize the hydraulic hose in the vulcanizing boiler equipment, and the press cloth is really important to protect the hydraulic hose during the vulcanizing process. The rich steam heating will mature the rubber material, making rubber molecules become closer, to give the hydraulic hose stable performance.

Of course, vulcanized rubber is much more stable than natural rubber. The vulcanizing process is also necessary for producing hydraulic hose with high quality.

The vulcanization for hydraulic hose production is the process that changes the synthetic and natural rubber into cross-linked polymers. Sulfur is the vulcanization agent for natural rubber (other chemicals are also used if needed). Vulcanizing hydraulic hoses using sulfur with heat and high temperature can make the hydraulic hose’s physical structure much more durable and stable.

Here, we can make a smooth and wrapped hydraulic hose during this vulcanizing process, using different materials for rubber vulcanization.

Smooth hydraulic hose: Wrap the plastic-coated material before the vulcanizing process, and get the smooth surface of the hydraulic hose.

Wrapped hydraulic hose: Use the water press to wrap the hydraulic hose, to get the special cloth marks overlapping the water cloth after the vulcanizing process, and then remove the water press. the cloth mark will be imprinted on the surface of the hydraulic hose permanently.

If you want to know the differences between the smooth vs wrapped hydraulic hose, please feel free to contact us to get free samples.

And remove the press cloth after the steaming process in the vulcanizing boiler.

We finally get the hydraulic hose printed with specifications after removing the press cloth.

Pressure Test

We need to have pressure testing to test the quality of the hydraulic hose, by measuring the burst pressure and high pressure.

Pack Hydraulic Hose

We will use the hydraulic pipe rolling machine to roll the qualified hydraulic hose after the strict pressure test and get ready for the packing process.

We use the woven bag to pack the hydraulic hose. The packing material is different though, plastic film and the woven bag are the most popular to pack the hydraulic hose, and the packing material is strong enough to store the hydraulic hose inside well. And the packed hydraulic hose rolls are also much easier to be stacked well in the hydraulic hose warehouse before loading time.

What’s more, we can print your logo or something you want on the surface of the hydraulic hose packing material, including your hydraulic hose brand name, hydraulic hose model number and etc. The printed text is helpful for you to know what hydraulic hose is inside the packing film.

Hydraulic Hose Manufacturing Equipment

The production of hydraulic hoses involves a complex process that requires specialized equipment. Here are the primary types of equipment used in hydraulic hose manufacturing:

Core Wire Extrusion Machine

- Purpose: Extrudes the inner core wire, which provides structural support to the hose.

- Process: Melts and extrudes the wire material, typically steel or synthetic fiber, onto a mandrel.

Rubber Extrusion Machine / Hydraulic Hose Extruder

- Purpose: Extrudes the rubber layers that form the hose’s inner and outer layers.

- Process: Melts and extrudes rubber compounds onto the core wire, creating a tube-like shape.

Hydraulic Hose Braiding Machine

- Purpose: Applies a braided layer of wire or textile fibers over the rubber layers for additional strength and reinforcement.

- Process: Winds wire or textile fibers around the rubber tube, creating a braided layer.

Covering Machine

- Purpose: Applies an outer layer of rubber or other material to protect the hose from abrasion, weather, and other environmental factors.

- Process: Extrudes a layer of material over the braided layer, forming the final outer layer of the hose.

Hydraulic Hose Crimping Machine

- Purpose: Attaches fittings to the ends of the hose, ensuring a secure and leak-proof connection.

- Process: Applies pressure to the fitting and hose, crimping them together.

Hydraulic Hose Cutting Machine

- Purpose: Cuts the hose to the desired length.

- Process: Uses a specialized cutting tool to accurately cut the hose.

Hydraulic Hose Testing Equipment

- Purpose: Ensures the quality and performance of the hoses.

- Process: Conducts tests such as pressure testing, burst testing, and flex testing.

Additional Equipment:

- Mixing Machines: Mix rubber compounds and other materials.

- Calendering Machines: Flatten rubber sheets for specific applications.

- Curing Presses: Vulcanize rubber components to improve their properties.

- Inspection Equipment: Visual inspection, dimensional checks, and other quality control measures.

The specific equipment and processes used can vary depending on the type of hose being manufactured and the manufacturer‘s production methods. However, these are the core components of a typical hydraulic hose manufacturing facility.

Here is a video showing you how to pack the hydraulic hose using the manual hydraulic hose packing machine.

Keep Hydraulic Hose in Warehouse

The finished hydraulic hose will be kept in our big hydraulic hose warehouse before shipping. All hydraulic hose will be stored well, before loading them to the shipping container.

Ship Hydraulic Hose

We will use the forklift with wooden pallets to send the packed hydraulic hose to the container, and the wooden pallets can protect the hydraulic hose away from damage.

Well done!

Conclusion

This is the complete hydraulic hose manufacturing process step by step, and finally please don’t hesitate to contact us to get Free hydraulic hose samples. For more, you can get the Hydraulic Hose Catalog PDF from us if you are interested in hydraulic hose pipes.

Related: