Brake hoses are a critical, yet often overlooked, component of your vehicle’s braking system. These flexible lines are responsible for delivering the pressurized brake fluid from the master cylinder to the calipers or wheel cylinders. Understanding their function and importance is key to ensuring your safety on the road.

This guide will provide a comprehensive look at everything you need to know about brake hoses. We’ll explore their purpose, the different materials they’re made from, and how to identify signs of wear and tear. You’ll also learn why regular inspections and timely replacements are essential for maintaining a reliable braking system.

What is a Brake Hose?

A brake hose is a flexible conduit that delivers hydraulic pressure to the wheel brakes of a vehicle. Unlike the rigid metal brake lines that run along the vehicle’s frame, the hoses are made of reinforced rubber or braided stainless steel to allow for the constant movement of the wheels and suspension.

When you press the brake pedal, fluid is pushed from the master cylinder through the brake lines and then into the hoses, which connect to the brake calipers or wheel cylinders at each wheel.

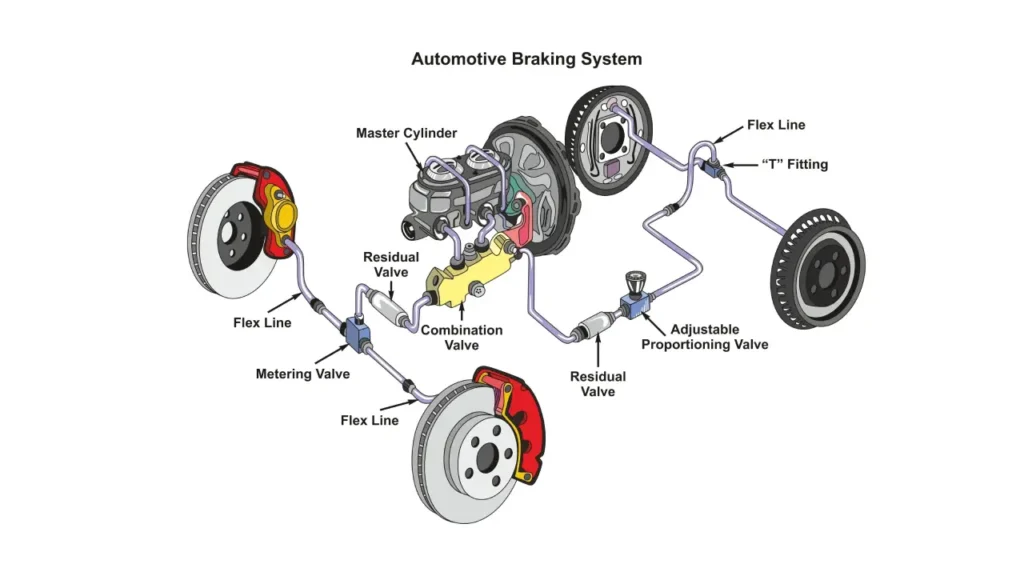

Automotive Brake System

An automotive brake system is a complex network of components that work together to safely stop a moving vehicle. It operates on the principle of hydraulics, where a small force applied at the brake pedal is converted into a large force at the wheels to generate friction. This system is a critical safety feature, and each component plays a specific role in ensuring reliable stopping power under various driving conditions.

- Master Cylinder: The heart of the hydraulic system, which converts the mechanical force from the brake pedal into hydraulic pressure.

- Brake Booster: A device that assists the driver by multiplying the force applied to the brake pedal, making it easier to stop the car.

- Combination Valve: A safety component that often combines several functions, including a proportioning valve to prevent rear wheel lock-up, a metering valve to balance front and rear braking, and a pressure differential switch to warn of a system pressure loss.

- Residual Valves: Small one-way check valves that maintain a minimal amount of pressure in the brake lines to ensure a quicker response and to prevent fluid from draining back into the master cylinder.

- Brake Lines & Hoses: The conduits that carry the pressurized brake fluid to the wheels. The lines are rigid metal tubes, while the hoses are flexible to accommodate the movement of the suspension and steering.

- Brake Calipers and Rotors (Disc Brakes): The caliper uses hydraulic pressure to clamp brake pads against the rotating rotor, creating friction to slow the vehicle.

- Wheel Cylinders and Brake Drums (Drum Brakes): The wheel cylinder pushes brake shoes outward against the inside of the rotating brake drum to create friction.

How Does a Brake Hose Work?

A brake hose is a vital component of a vehicle’s hydraulic braking system. Its main function is to transfer the high-pressure brake fluid from the rigid brake lines, which are fixed to the vehicle’s chassis, to the brake calipers or wheel cylinders located at each wheel. This is an essential job because the wheels and suspension are constantly moving up and down and the front wheels turn for steering.

The flexibility of the hose allows it to accommodate this movement without cracking or leaking, ensuring that braking force is consistently and reliably applied. When you press the brake pedal, the master cylinder pressurizes the fluid, and the brake hose, being a non-compressible fluid, effectively transmits this pressure to engage the brakes.

- Fluid Transfer: It acts as the final conduit for the pressurized brake fluid, delivering it to the brake components at each wheel.

- Flexibility: Its flexible construction, typically of reinforced rubber or braided stainless steel, allows for the independent movement of the wheels and suspension.

- Pressure Resistance: It is designed to resist expansion under high hydraulic pressure, ensuring that the force from the brake pedal is efficiently converted into stopping power.

What is a Brake Hose Made of?

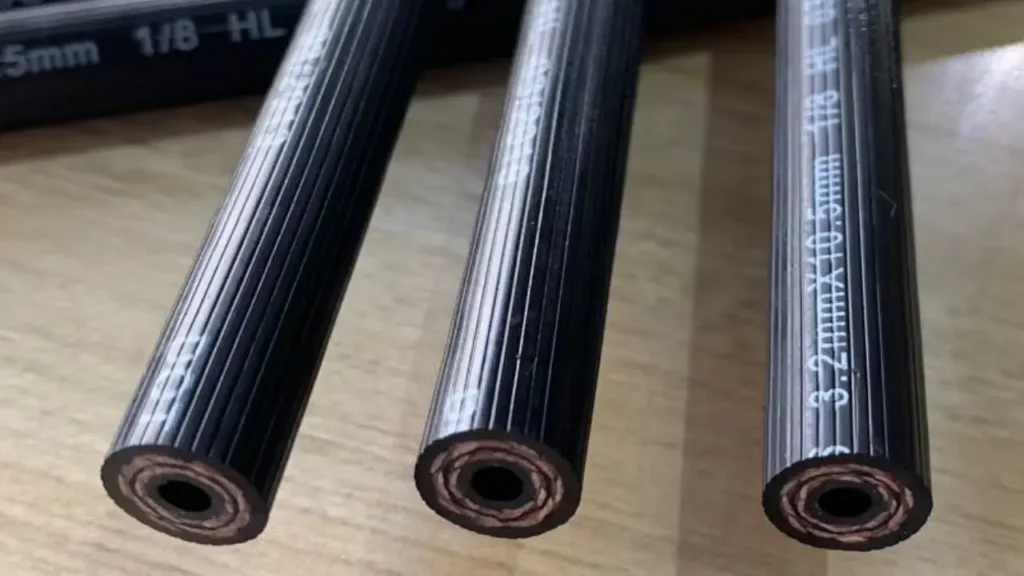

Brake hoses are manufactured to withstand the intense pressures and movements of a vehicle’s braking system. While the specific composition may vary, they generally fall into two main categories: rubber and stainless steel braided hoses. The construction of a typical rubber brake hose includes multiple layers to ensure both flexibility and strength.

- Inner Tube: This is the innermost layer, typically made of a synthetic rubber blend that is compatible with brake fluid.

- Reinforcement Layers: Wrapped around the inner tube are layers of textile or synthetic fibers, which provide the hose with its crucial strength to resist expansion under high pressure.

- Outer Cover: The outermost layer is a durable rubber cover that protects the hose from external factors like heat, moisture, road chemicals, and physical abrasion.

Alternatively, stainless steel braided brake hoses feature a braided steel mesh on the exterior of a synthetic rubber or Teflon (PTFE) inner tube. This steel mesh significantly reinforces the hose, preventing it from expanding under pressure and offering greater resistance to damage.

What is Brake Hose Used for?

Brake hoses serve a crucial role in a vehicle’s hydraulic braking system by acting as the flexible connection between the rigid brake lines and the moving components at each wheel. Their primary purpose is to safely transmit the immense hydraulic pressure from the master cylinder to the brake calipers or wheel cylinders.

This flexibility is essential because it allows the wheels to move independently with the suspension and for the front wheels to turn for steering without damaging the fluid lines. Here are some brake hose applications in the following:

- Fluid Transfer: They are the final segment of the brake system’s fluid pathway, delivering pressurized brake fluid to the braking components at the wheels.

- Accommodating Movement: Their flexible design is engineered to withstand the constant up-and-down motion of the suspension and the side-to-side turning of the steering, preventing the rigid brake lines from cracking or failing.

- Maintaining Pressure: A well-maintained hose is designed to resist expansion under high pressure, ensuring that all the force from the brake pedal is efficiently translated into braking force, providing a firm and responsive pedal feel.

Types of Brake Hose

While all brake hoses perform the same fundamental task, they come in a few different types, primarily distinguished by their materials and construction. The right type of hose for a vehicle depends on a balance of performance, durability, and cost. Understanding these variations is key to selecting the right components for any braking system.

Rubber Brake Hoses

These are the most common type of brake hoses found on the vast majority of production vehicles. They are constructed from multiple layers, including a synthetic rubber inner tube, reinforcement layers of braided textile fibers, and a protective outer cover of durable rubber. Rubber hoses are known for their cost-effectiveness and flexibility, making them a reliable choice for standard road conditions. They are designed to meet strict safety standards and provide consistent performance under normal operating pressures.

Stainless Steel Braided Brake Hoses

Often referred to as “performance brake hoses,” these are a popular upgrade for a variety of vehicles. They feature a synthetic rubber or Teflon (PTFE) inner tube encased in a tightly woven layer of stainless steel braid. This steel mesh prevents the hose from expanding under extreme pressure, which results in a firmer, more responsive brake pedal feel. They are also highly resistant to abrasion and damage from road debris, offering superior durability over standard rubber hoses.

Hybrid Brake Hoses

Hybrid brake hoses combine the benefits of both rubber and stainless steel. They typically feature a rubber core with an external stainless steel braiding. This design aims to offer the flexibility of a rubber hose while gaining the added pressure resistance and durability of the steel mesh. They are a good middle-ground option for those seeking a performance upgrade without the full cost of a purely stainless steel line.

How to Choose Suitable Brake Hoses?

Choosing the right brake hose is a critical decision that directly impacts your vehicle’s safety and braking performance. It’s not a one-size-fits-all component, and the best choice depends on your vehicle, driving habits, and budget. When making a selection, consider the following key factors to ensure you get a safe and effective product.

- Vehicle Specifications: Always choose a hose that matches the specific make, model, and year of your vehicle. This ensures the correct length, diameter, and fitting types to prevent leaks and ensure proper function. OEM (Original Equipment Manufacturer) parts are a safe bet, as they are guaranteed to fit and perform as designed.

- Material: The two main options are standard rubber hoses and stainless steel braided hoses. Rubber hoses are a cost-effective choice for most daily drivers, offering reliable performance. Stainless steel hoses, while more expensive, are a popular upgrade for high-performance vehicles or for drivers who desire a firmer, more responsive brake pedal feel, as they are less prone to expansion under pressure.

- Quality and Reputation: A brake hose is a safety-critical part. Purchase from a reputable manufacturer or supplier known for producing high-quality, durable products. Look for hoses that meet or exceed industry standards. A cheap, low-quality hose is a risk you should never take.

- Fittings and Connections: Ensure that the fittings on the hose are made of corrosion-resistant materials and are compatible with your vehicle’s brake lines. Mismatched fittings can lead to dangerous leaks and system failure.

Conclusion

In conclusion, brake hoses are a vital part of your car’s safety system. Their role in transmitting hydraulic pressure is indispensable for effective braking. Regular inspections and understanding the signs of wear are crucial steps in preventing brake failure. Never underestimate the importance of these seemingly simple components; they are your first line of defense in a critical situation.

Maintaining a reliable braking system is paramount for vehicle safety. By choosing high-quality brake hoses, you are investing in peace of mind. Remember that even the best brake pads and rotors cannot perform without the proper fluid delivery. Ensure your entire braking system is up to par with premium components.

For automotive repair shops and enthusiasts alike, having access to durable and dependable brake hoses is essential. We at Kingdaflex specialize in providing top-tier hydraulic solutions. You can get wholesale brake hoses directly from us to guarantee the quality and reliability your customers deserve.