Malleable iron fittings are essential components in various piping systems, known for their strength and versatility. This guide explores their properties, applications, and benefits, providing a comprehensive understanding for professionals and DIY enthusiasts alike.

From their manufacturing process to installation tips, we’ll delve into the world of malleable iron fittings. Discover how these robust fittings withstand demanding conditions and ensure reliable connections in diverse industrial and residential settings.

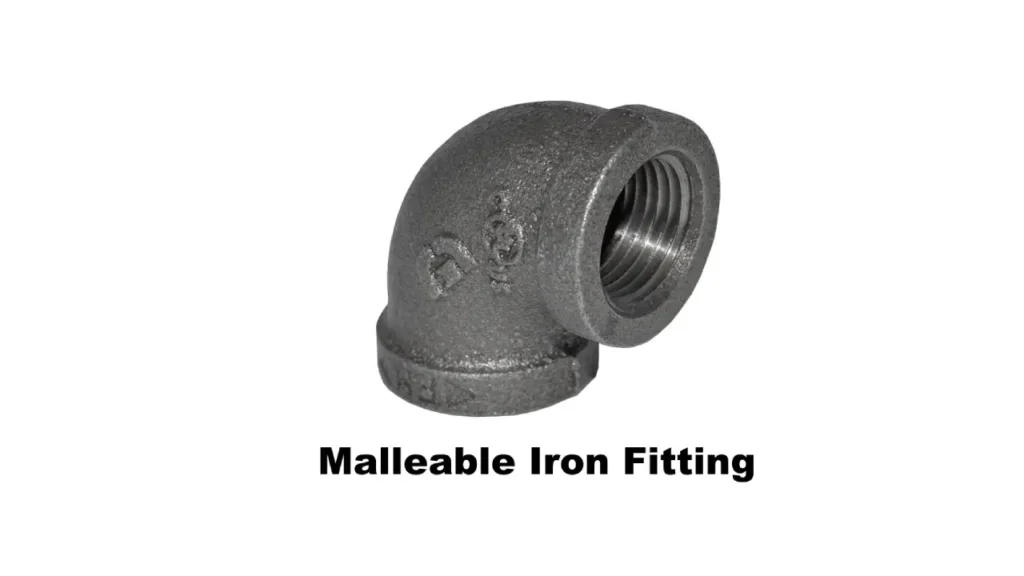

What is Malleable Iron Fittings

Malleable iron fittings are pipe fittings made from a specific type of cast iron that has undergone a heat treatment process called “malleabilization.” This process transforms the brittle white cast iron into a more ductile and strong material, allowing it to withstand higher levels of stress and impact compared to standard cast iron fittings. The result is a fitting that retains the strength of iron while gaining improved flexibility and resistance to cracking.

These fittings are widely used in plumbing, gas, and other piping systems due to their durability and versatility. They are particularly valued for their ability to withstand high pressures and temperatures, making them suitable for demanding applications. Malleable iron fittings also offer excellent corrosion resistance, especially when galvanized, further extending their lifespan and reliability.

What is Malleable Iron Fittings Made of

Malleable iron fittings begin as white cast iron, which is a hard and brittle alloy of iron and carbon. This initial material contains carbon in the form of iron carbide, making it extremely hard but also susceptible to fracturing under stress. The defining characteristic of malleable iron is the specific heat treatment it undergoes.

The process, known as malleabilization, involves heating the white cast iron to a high temperature, typically around 900°C (1650°F), and holding it there for an extended period, often several days. This prolonged heating causes the iron carbide to decompose, resulting in the formation of irregularly shaped nodules of free carbon, known as temper carbon or nodular graphite, dispersed throughout the iron matrix.

This transformation from iron carbide to temper carbon significantly alters the material’s properties. The resulting malleable iron exhibits increased ductility, tensile strength, and impact resistance. It retains the inherent strength of cast iron but gains the ability to deform under stress without fracturing, making it ideal for applications where durability and reliability are crucial.

Malleable Iron Fitting Types

Malleable iron fittings offer diverse solutions for piping needs. Their robust nature and varied designs cater to numerous applications. Understanding the different types ensures you select the right fitting for optimal performance and system integrity.

1. Threaded Fittings

Threaded malleable iron fittings are the most common type, featuring tapered threads (typically NPT) that allow for secure and leak-proof connections. They’re used in a wide range of applications, from plumbing and gas lines to industrial piping systems. The threaded design facilitates easy assembly and disassembly, making them versatile for installations and repairs. These fittings come in various shapes, including elbows, tees, couplings, and unions.

2. Unions

Malleable iron unions are designed to connect two pipes or fittings in a way that allows for easy disconnection and reconnection. They consist of three parts: two threaded end pieces and a center nut. Unions are essential for applications where frequent maintenance or disassembly is required, providing a convenient way to separate sections of piping without cutting or damaging the pipes. They are often used in systems that require periodic cleaning or inspection.

3. Elbows

Malleable iron elbows are used to change the direction of piping, typically at 45-degree or 90-degree angles. They are crucial for navigating obstacles and creating turns in piping systems. Their robust construction ensures they can withstand high pressures and temperatures, making them suitable for demanding applications. Elbows are widely used in plumbing, gas, and industrial piping, providing reliable directional changes.

4. Tees

Malleable iron tees are three-way fittings used to connect three pipes, allowing for branching or combining fluid flow. They are essential for creating complex piping networks and distributing fluids or gases to multiple outlets. Tees come in various configurations, including equal tees (all three openings are the same size) and reducing tees (one or more openings are smaller). Their strong construction ensures they can handle the pressures and stresses of various piping systems.

5. Couplings

Malleable iron couplings are used to join two pipes of the same diameter, creating a straight connection. They are essential for extending pipe lengths or repairing damaged sections. Couplings provide a secure and leak-proof connection, ensuring the integrity of the piping system. They are widely used in plumbing, gas, and industrial applications, providing a reliable way to join pipes.

6. Plugs and Caps

Malleable iron plugs and caps are used to close off the ends of pipes or fittings. Plugs have external threads and screw into the internal threads of a fitting, while caps have internal threads and screw onto the external threads of a pipe. They are essential for sealing unused outlets or preventing leaks during testing or maintenance. Plugs and caps provide a durable and reliable way to terminate piping connections.

Why Use Malleable Iron Fittings

Malleable iron fittings offer a blend of strength and adaptability. Their robust construction and resistance to harsh conditions make them a top choice for reliable piping systems.

Durability and Strength:

Malleable iron fittings are engineered to endure significant mechanical stress and high-pressure environments. Their robust composition ensures they maintain structural integrity, even under demanding conditions. This makes them ideal for applications where reliability is paramount, preventing costly failures and downtime.

Ductility:

The unique malleabilization process enhances the material’s ductility, allowing it to deform rather than fracture under stress. This crucial property makes malleable iron fittings particularly effective in systems subject to vibrations, thermal expansion, or sudden impacts, where rigid materials might fail.

Corrosion Resistance:

Especially when treated with galvanization, malleable iron fittings exhibit exceptional resistance to rust and corrosion. This characteristic is essential for applications in humid or corrosive environments, extending the lifespan of the fittings and maintaining system integrity over time.

High Temperature Resistance:

Malleable iron fittings can withstand elevated temperatures, making them suitable for applications involving steam, hot gases, and other high-temperature fluids. This thermal stability ensures that the fittings maintain their structural integrity and sealing capabilities in demanding thermal conditions.

Versatility:

The wide array of sizes, shapes, and thread configurations available for malleable iron fittings allows for their use in diverse piping systems. Their adaptable nature makes them suitable for everything from simple plumbing repairs to complex industrial installations. Threaded connections also add to the versitility, making assembly and disassembly much easier.

Reliability:

Malleable iron fittings are known for their ability to create secure, leak-proof connections. This reliability is critical in applications where fluid or gas leakage could lead to safety hazards or operational disruptions. Properly installed malleable iron fittings provide peace of mind, knowing the system is secure.

Long Service Life:

The combined benefits of strength, corrosion resistance, and thermal stability contribute to the extended service life of malleable iron fittings. This longevity reduces the frequency of replacements and maintenance, resulting in cost savings and minimizing disruptions to operations.

How to Use Malleable Iron Fittings

When working with piping systems, knowing how to use malleable iron fittings is essential. Whether you’re a DIY enthusiast or a professional, mastering these steps will ensure you create secure, leak-free connections.

Step 1. Gather Necessary Tools and Materials

Before starting, gather all the tools and materials you’ll need. This includes the malleable iron fittings, pipe thread sealant (pipe dope or Teflon tape), pipe wrenches, measuring tape, pipe cutter or saw, and safety glasses. Ensuring you have everything on hand will streamline the process and prevent interruptions. Safety is paramount; wear safety glasses to protect your eyes from metal shavings or sealant.

Step 2. Prepare the Pipes

Accurately measure and cut the pipes to the required lengths. Use a pipe cutter or saw to make clean, square cuts. Remove any burrs or sharp edges from the pipe ends using a file or deburring tool. Clean the pipe threads thoroughly to remove any dirt, debris, or old sealant. This ensures a proper seal and prevents leaks. Proper pipe preparation is essential for a reliable connection.

Step 3. Apply Pipe Thread Sealant

Apply pipe thread sealant to the male threads of the pipe or fitting. Use either Teflon tape or pipe dope. If using Teflon tape, wrap it clockwise around the threads two to three times. If using pipe dope, apply an even coat to the threads. Avoid applying sealant to the first two threads to prevent it from entering the piping system. The sealant creates a leak-proof seal by filling any gaps between the threads.

Step 4. Connect the Fittings

Thread the malleable iron fitting onto the pipe by hand, turning it clockwise. Once hand-tight, use a pipe wrench to tighten the fitting further. Apply sufficient torque to create a secure connection, but avoid overtightening, as this can damage the fitting or pipe threads. Ensure the fitting is aligned correctly and that the threads are fully engaged. A properly tightened fitting will prevent leaks and ensure system integrity.

Step 5. Test the Connection

After assembling the fittings, test the connection for leaks. For water systems, turn on the water supply and check for any signs of leakage. For gas systems, use a soap solution or a gas leak detector to check for leaks. If any leaks are detected, tighten the fittings further or disassemble and reapply sealant. Thorough testing ensures the system is safe and leak-free before being put into service.

Get Malleable Iron Fittings Now

Malleable iron fittings stand as a testament to durability and versatility in piping systems. Their robust construction and corrosion resistance make them essential for both simple and complex installations. This guide has illuminated their key features and applications, underscoring their reliable performance.

For those seeking high-quality malleable iron fittings, Kingdaflex offers a comprehensive selection. We prioritize providing fittings that meet stringent industry standards, ensuring your projects benefit from superior quality and long-lasting performance. Explore our online catalog today.

Enhance your piping projects with the proven strength of malleable iron. Visit Kingdaflex now to browse our range and buy your Malleable Iron Fittings, ensuring reliable connections for your applications.