Kingdaflex is your premier manufacturer for 1/2 inch hydraulic hoses (DN12). We supply the full spectrum of industrial hoses—from standard hydraulic repairs to extreme high-pressure mining applications—at bulk wholesale prices.

Available 1/2″ Configurations:

At Kingdaflex, we manufacture a versatile range of 1/2 inch hydraulic hoses designed to meet specific pressure ratings and application environments. Whether you need standard replacements or specialized compact solutions, we have the right fit.

The 2SN SAE 100R2AT 1/2″ is our best-selling industry standard designed specifically for high-pressure applications.

Constructed with two braids of high-tensile steel wire, this hose delivers exceptional balanced flexibility and durability against external impulse loads.

It is engineered to perform reliably in demanding construction and mining equipment environments requiring working pressures up to 4000 Psi.

For medium-pressure hydraulic lines, our SAE 100R1AT offers a cost-effective single wire braid construction.

It is specifically designed for agricultural machinery and light industrial systems where pressure ratings of 3000 Psi or lower are sufficient.

This hose provides a reliable solution for standard hydraulic applications without the added weight of double-braided alternatives.

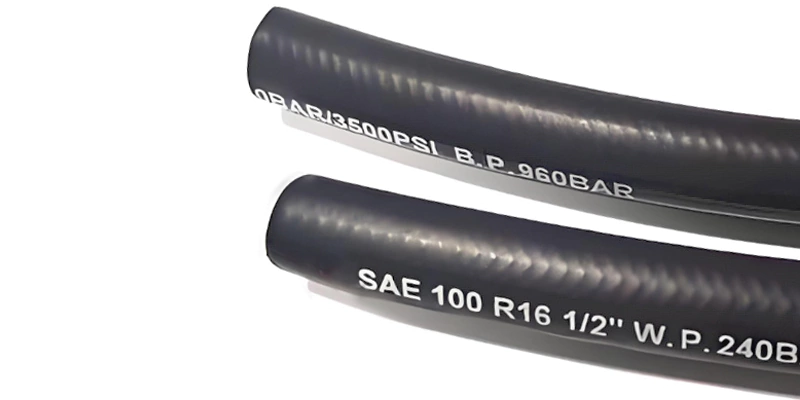

When installation space is limited, the SAE 100R16 1/2 hydraulic hose provides the robust high-pressure performance of standard R2 specifications but with a significantly slimmer profile.

Its primary advantage is a 50% tighter bend radius compared to standard hoses, making it the perfect choice for routing through complex, narrow spaces found in modern mobile equipment and forklifts.

Designed for low-pressure utility, the SAE 100R6 / EN854 1/2″-DN features a textile braided reinforcement suitable for oil, fuel, and return lines.

This SAE 100R6 1/2 hydraulic hose is exceptionally lightweight and highly flexible, making it the ideal choice for hydraulic signal lines and lubricating oil systems where high pressure is not required.

| Hose Standard | Hose ID (mm) | Hose OD (Max mm) | Working Pressure (Bar / PSI) | Burst Pressure (Bar / PSI) | Min Bend Radius (mm) |

| SAE 100 R1AT / 1SN | 12.7 | 21.4 | 160 / 2320 | 640 / 9280 | 180 |

| SAE 100 R2AT / 2SN | 12.7 | 23.0 | 275 / 3990 | 1100 / 15950 | 180 |

| SAE 100 R16 | 12.7 | 22.0 | 275 / 3990 | 1100 / 15950 | 90 |

| SAE 100 R17 | 12.7 | 21.1 | 210 / 3045 | 840 / 12180 | 90 |

| EN 856 4SP | 12.7 | 25.4 | 415 / 6020 | 1660 / 24070 | 230 |

| SAE 100 R12 | 12.7 | 24.6 | 280 / 4060 | 1120 / 16240 | 180 |

| SAE 100 R15 | 12.7 | 26.8 | 420 / 6090 | 1680 / 24360 | 200 |

| SAE 100 R3 (Textile) | 12.7 | 24.6 | 70 / 1015 | 280 / 4060 | 125 |

| SAE 100 R6 (Textile) | 12.7 | 19.7 | 28 / 406 | 112 / 1624 | 100 |

Features: Traditional fabric impression finish. Provides a rugged, non-slip grip and excellent resistance to harsh weather and ozone.

Best For: Heavy-duty outdoor machinery (Excavators, Earthmovers).

Features: Sleek, flat surface finish. It creates less friction when hoses rub against each other and prevents dirt accumulation.

Best For: Mobile machinery where cleanliness and abrasion resistance are priorities.

Don’t just buy the hose—get the complete solution. We provide factory-crimped assemblies tested for leak-free performance, helping you reduce labor costs and equipment downtime.

Reliable power transmission for excavators, tractors, and earthmovers. Our wrapped cover hoses resist abrasion in harsh, muddy, and rocky environments.

Precision fluid transfer for hydraulic presses and injection molding machines. Designed to maintain stable flow rates under constant pressure.

Compact routing solutions for forklifts, loaders, and aerial lifts. Our R16/R17 series offers superior flexibility for tight installation spaces.

High-performance lines for hydraulic braking, power steering, and fluid delivery systems in commercial vehicles and trucks.

Quality is non-negotiable. Every batch of our SAE 100R2AT 1/2″ hose undergoes strict impulse testing (up to 200,000 cycles) to ensure it exceeds international safety standards before it leaves the factory.

The recommended flow rate depends on your system’s application. For pressure lines, we recommend a flow rate of 10 to 12 GPM (Gallons Per Minute) to ensure efficient fluid velocity. For return lines (using lower pressure hoses like SAE 100R6), the flow rate can be slightly higher depending on the pump capacity.

The OD varies by hose type and reinforcement layers.

Yes, but you must select the correct model. Standard 1-wire hoses (R1) are typically rated for ~2300 Psi. For 4000 Psi applications, you must use our SAE 100 R2AT (2-Wire Braided) or 4SP (4-Wire Spiral) hoses to ensure safety and performance.

Yes, we support distributors and manufacturers fully. We can provide free samples (typically 1 meter) for quality testing. We also offer OEM services, allowing us to print your brand logo, part number, and specifications directly on the bulk hydraulic hose layline.