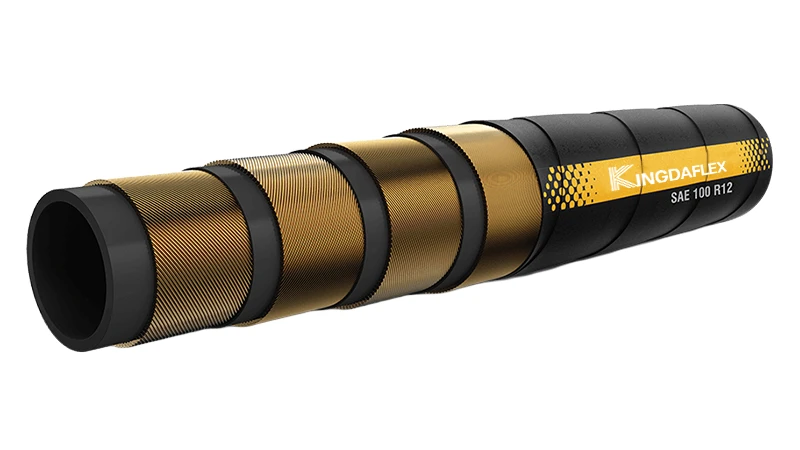

Kingdaflex manufactures SAE J517 100R12 hydraulic hoses engineered for high-pressure and high-impulse applications. Designed with multi-layer spiral steel reinforcement, our hoses deliver stable performance in demanding industrial environments.

| Size | Inside (mm) | Braid (mm) | Outside (mm) | Working Pressure | Burst Pressure | Bend Radius | Weight | Length | ||||||||

| DN | inch | mm | Dash | Min | Max | Min | Max | Min | Max | Bar | Psi | Bar | Psi | mm | kg/m | M |

| 13 | 1/2″ | 12.7 | -8 | 12.3 | 13.5 | 19.9 | 21.5 | 23.0 | 24.6 | 280 | 4060 | 1120 | 16240 | 180 | 0.80 | 40 |

| 16 | 5/8″ | 16.0 | -10 | 15.5 | 16.7 | 23.8 | 25.4 | 26.6 | 28.2 | 280 | 4060 | 1120 | 16240 | 200 | 0.98 | 40 |

| 19 | 3/4″ | 19.0 | -12 | 18.6 | 19.8 | 26.9 | 28.4 | 29.9 | 31.5 | 280 | 4060 | 1120 | 16240 | 240 | 1.45 | 40 |

| 25 | 1″ | 25.4 | -16 | 25.0 | 26.4 | 34.1 | 35.7 | 36.8 | 39.2 | 280 | 4060 | 1120 | 16240 | 300 | 2.05 | 40 |

| 32 | 1-1/4″ | 31.8 | -20 | 31.4 | 33.0 | 42.7 | 45.1 | 45.7 | 48.6 | 210 | 3000 | 840 | 12000 | 230 | 2.18 | 40 |

| 38 | 1-1/2″ | 38.1 | -24 | 37.7 | 39.3 | 49.2 | 51.6 | 51.8 | 55.0 | 210 | 3000 | 840 | 12000 | 420 | 2.73 | 40 |

| 51 | 2″ | 50.8 | -32 | 50.4 | 52.0 | 62.5 | 64.8 | 66.8 | 68.3 | 210 | 3000 | 840 | 12000 | 560 | 3.94 | 40 |

The performance of SAE 100R12 hydraulic hose is defined by its multi-layer spiral construction. Unlike standard braided hoses, 100R12 is engineered specifically for high-pressure and high-impulse hydraulic systems. Its structure consists of three primary components: the inner tube, spiral steel wire reinforcement, and outer cover.

The inner tube is manufactured from oil-resistant synthetic rubber designed to handle petroleum-based hydraulic fluids. It provides excellent resistance to hydraulic oil, temperature variations, and internal pressure stress. The smooth internal surface reduces flow resistance and helps maintain stable fluid transmission under high operating pressure.

The material formulation is optimized for durability and long-term compatibility with industrial hydraulic systems.

SAE 100R12 features four layers of high-tensile steel wire arranged in a spiral configuration. This spiral reinforcement structure is the defining characteristic of R12 hose.

Unlike braided reinforcement, where wires are interwoven at alternating angles, spiral reinforcement uses parallel layers of steel wire wound in opposite directions. This design significantly improves pressure capacity, impulse resistance, and fatigue life under dynamic loading conditions.

The outer cover is made from abrasion-resistant and weather-resistant synthetic rubber. It protects the reinforcement layers from mechanical damage, ozone exposure, oil contamination, and harsh environmental conditions.

In demanding applications such as construction or mining machinery, the outer cover plays a critical role in maintaining hose integrity against external wear and surface abrasion.

Used in excavators and loaders for high-pressure hydraulic power transmission.

Handles extreme pressure in drills, crushers, and underground equipment systems.

Suitable for high-pressure hydraulic control systems and offshore equipment.

Applied in heavy-duty hydraulic presses and manufacturing machinery circuits.

Private labeling and hose marking available for distributors and OEM customers.

Hoses supplied in specified lengths to match equipment installation requirements.

Enhanced abrasion-resistant or weather-resistant outer covers for severe-duty environments.

Professional crimping services with controlled crimp diameter and fitting retention verification.

SAE 100R12 hydraulic hose is a high-pressure spiral steel wire reinforced hose defined under the SAE J517 standard. It is specifically engineered for heavy-duty hydraulic systems that operate under high working pressure and frequent impulse cycles. Unlike braided hydraulic hoses, SAE 100R12 features four layers of spiral-wound high-tensile steel wire reinforcement, providing enhanced strength and pressure stability.

This hose type is designed to handle demanding hydraulic applications where pressure spikes, vibration, and continuous dynamic loading are present. The multi-layer spiral construction improves fatigue resistance and extends service life in severe operating environments.

When selecting a hydraulic hose for high-pressure systems, SAE 100R12 is often chosen for its balance between pressure capacity, durability, and long-term operational reliability.

SAE 100R12, SAE 100R13, and SAE 100R15 are all spiral-reinforced hydraulic hoses designed for high-pressure applications. However, they differ in reinforcement structure, impulse resistance, and performance level under severe working conditions. Understanding these differences helps engineers select the correct hose type for specific hydraulic systems.

| Feature | SAE 100R12 | SAE 100R13 | SAE 100R15 |

|---|---|---|---|

| Reinforcement Type | Spiral steel wire | Spiral steel wire | Spiral steel wire |

| Spiral Layers | 4 layers | 4 or 6 layers | 4 or 6 layers |

| Pressure Capacity | High pressure | Higher pressure | Ultra high pressure |

| Impulse Resistance | High | Very high | Extremely high |

| Flexibility | Moderate | Moderate | Slightly stiffer |

| Typical Application | General heavy-duty equipment | Severe-duty hydraulic systems | Extreme-duty & high-impulse systems |

SAE 100R12 hydraulic hose is designed for high-pressure hydraulic systems, and its working pressure varies depending on the hose size. Smaller diameters generally support higher pressure ratings, while larger sizes are rated slightly lower according to SAE J517 standards.

In addition to working pressure, 100R12 hoses are manufactured with a safety factor, meaning burst pressure is significantly higher than the rated working pressure. This design ensures reliability in demanding applications where pressure spikes and dynamic loading occur.

Yes, SAE 100R12 is a spiral-reinforced hydraulic hose. It features four layers of high-tensile steel wire arranged in a spiral configuration. Unlike braided hoses, which use interwoven wire reinforcement, spiral hoses use parallel layers wound in alternating directions. This structure provides improved pressure capacity and impulse resistance. Spiral reinforcement distributes stress more evenly across the hose body, making 100R12 suitable for heavy-duty and high-pressure hydraulic applications where durability and fatigue resistance are critical.

SAE 100R12 hoses are commonly used in heavy-duty hydraulic systems where high working pressure and repeated pressure cycles are present. Typical applications include construction machinery, mining equipment, hydraulic presses, and industrial hydraulic power units.

These environments often involve vibration, dynamic movement, and pressure spikes, requiring a hose with strong structural reinforcement. The four-layer spiral design of R12 makes it well-suited for demanding fluid transmission systems that require long service life and stable performance.

SAE 100R12 hydraulic hose is constructed with four layers of spiral steel wire reinforcement. These layers are wound in alternating directions to improve pressure handling capability and fatigue resistance. The multi-layer spiral structure distinguishes R12 from braided hose types and allows it to withstand high working pressures and impulse loads.

The four-layer design provides a balance between strength, flexibility, and durability in high-pressure hydraulic systems.