Ditch the wrench! Swage fittings install in seconds – no tools required. Save time and money on your next plumbing project with secure, leak-proof connections. Upgrade your plumbing the smarter way – shop swage fittings now!

Kingdaflex is a leading manufacturer of hydraulic hoses and ferrules based in China. We focus on providing high-quality, cost-effective solutions for your hydraulic needs. We can customize any types of the hydraulic hose ferrules to meet your requirement for your hydraulic systems.

Swage fittings come in various materials like copper, brass, stainless steel, and even PEX-compatible plastics. Choose the material that best complements your existing plumbing system and application. For example, brass offers good corrosion resistance, while stainless steel is ideal for high-pressure lines.

Consider the pressure rating of your system and choose swage fittings that can handle the maximum pressure without compromising their integrity. This ensures a reliable and leak-free connection.

Swage fittings come in a wide range of sizes to accommodate different pipe diameters. Explore options like elbows, tees, reducers, and caps to create the specific connections your plumbing project requires.

While most swage fittings prioritize functionality, some boast a sleek or chrome finish. If exposed plumbing is part of your project’s aesthetic, you can choose swage fittings that complement your design vision.

When it comes to plumbing and hose connections, two main fitting options emerge: swage and swageless. Both offer secure methods for connecting pipes and hoses, but they have distinct advantages and disadvantages.

Here are the differences between swage and swagless fittings to help you decide which type best suits your needs:

Swage Fittings:

Swageless Fittings:

Choosing the Right Fit:

Frustrated with complicated plumbing connections? Swage fittings offer a quicker, easier way to go! Simply insert the tube – no tools needed! Get secure, leak-proof connections in seconds. Take control of your project – customize your swage fittings today!

Tired of unreliable cable connections? Take control with swage cable fittings! Create secure, high-strength terminations in seconds – no crimping or tools needed. Customize your project with various sizes and materials. Upgrade your cable connections today – experience the swage fitting difference!

Frustrated with traditional plumbing methods? Take control with axially swaged fittings! Enjoy secure, leak-proof connections in seconds with a simple push – no flame, clamps, or tools needed. Experience faster installations and save money on your next project. Upgrade to axially swaged fittings today!

Tired of soldering and leaky connections? Take control with copper swage fittings! Create secure, leak-proof connections in seconds, with no flame or tools needed. Enjoy a faster, easier plumbing experience and the timeless look of copper. Upgrade your plumbing now – Quote copper swage fittings today!

Fed up with messy leaks and unreliable connections? Take control of your hydraulic system! Hydraulic swage fittings deliver secure, high-pressure seals in seconds – no tools needed. Upgrade your equipment for maximum performance and peace of mind. Get hydraulic swage fittings now!

Want rock-solid connections that last? Build with confidence using stainless steel swage fittings! Their superior corrosion resistance and high-pressure tolerance make them ideal for demanding projects. Enjoy the ease of a tool-free installation and create secure, long-lasting connections in seconds. Upgrade to stainless steel swage fittings now!

Frustrated with complicated plumbing projects? Take control with swaged end fittings! Enjoy secure, leak-free connections in seconds – no tools needed! Customize size, material, and pressure rating for your exact needs. Simplify your plumbing and save time, and quote swaged end fittings now!

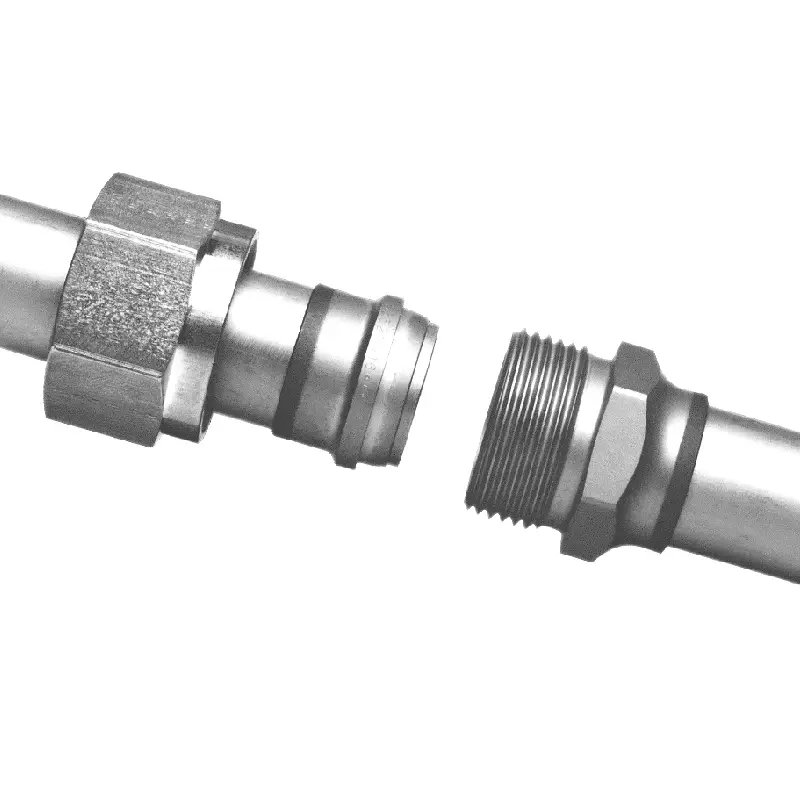

Tired of wrestling with wrenches? Threaded swage fittings offer the best of both worlds: secure like a swage, but finger-tighten for easy assembly. No tools needed for secure, leak-proof connections in seconds! Upgrade your plumbing – Get your desired threaded swage fittings now!

A swage fitting is a type of fitting used to create a secure and permanent connection between a pipe or hose and another fitting, valve, or another piece of pipe/hose.

Here’s a breakdown of its key features:

Connection Method: Swage fittings rely on a crimping process. A specialized tool compresses a sleeve or collar on the fitting around the inserted pipe or hose. This crimping action creates a tight grip that holds the components together.

Installation: The installation process involves inserting the pipe or hose into the fitting and then using a crimping tool to compress the sleeve or collar. Crimping tools come in various forms, from handheld options for smaller projects to hydraulic presses for larger-scale applications.

Swage fittings offer several advantages that make them a popular choice for plumbing and various other applications that require secure connections. Here’s a breakdown of their key benefits:

Fast Installation: Once you’ve got the hang of it, swaging can be a relatively quick process compared to other methods like soldering or brazing. The act of inserting the pipe and crimping the fitting takes minimal time.

Secure Connections: When installed correctly using the appropriate swage fitting and crimping tool, the swaging process creates a strong and reliable connection. The tight grip between the fitting and the pipe minimizes the risk of leaks or blowouts, even under pressure.

Cost-Effective: Swage fittings themselves are generally less expensive than some alternative connection methods. Additionally, the crimping tools needed for swaging can be found in various ranges, with some handheld options being affordable for DIY projects.

Versatility: Swage fittings come in various sizes and configurations to accommodate different pipe or hose diameters. They can also be used with various materials, like copper, PEX tubing, or even stainless steel, depending on the specific fitting type.

Relatively Simple Installation Process: While a swaging tool is required, the basic concept of inserting the pipe and crimping the fitting is straightforward. This makes swage fittings a good option for DIY projects compared to methods requiring soldering or complex techniques.

Here are some additional benefits to consider depending on the specific swage fitting type:

Swage fittings provide a good balance of speed, security, affordability, and ease of use for creating reliable connections in various plumbing and industrial applications.

Swage fittings are employed in various applications where secure, leak-proof connections are essential. Here are some common scenarios where they shine:

Plumbing Systems: In both residential and commercial settings, swage fittings are frequently used to connect pipes for water supply lines, drainage systems, and even gas lines (in some cases, where permitted by local building codes). They’re particularly suitable for copper and PEX tubing.

Hydraulic Lines: For machinery and equipment that relies on hydraulic systems to transmit power, swage fittings create secure connections within these high-pressure lines. They can be found in construction equipment, industrial machinery, and agricultural equipment.

Air Conditioning and Refrigeration Systems: Swage fittings are sometimes used in these systems to connect refrigerant lines or compressed air lines. However, it’s important to ensure the chosen swage fittings are compatible with the specific refrigerants or air pressure being used.

General Industrial Applications: Across various industries, swage fittings find use in applications requiring durable and leak-proof connections for conveying fluids, gases, or even abrasive materials. Examples include chemical processing plants, car washes, and water treatment facilities.

Marine Applications: In some instances, swage fittings might be used for specific applications on boats or marine equipment. However, due to the demanding saltwater environment, corrosion-resistant materials like stainless steel are crucial for the fittings in such cases. Local regulations and maritime safety standards also need to be strictly considered.

Key Points to Remember: