Conductive hoses are made from carefully selected materials that combine durability, flexibility, and electrical conductivity. Their construction ensures safe fluid transfer by preventing static electricity buildup, while resisting chemicals, heat, and wear. Different layers and components work together to provide long-lasting performance in demanding industrial applications.

Inner Tube: The inner tube is made from conductive or static-dissipative materials, such as synthetic rubber or specialized polymers, ensuring safe fluid flow while preventing static buildup, chemical reactions, and contamination during industrial or chemical handling.

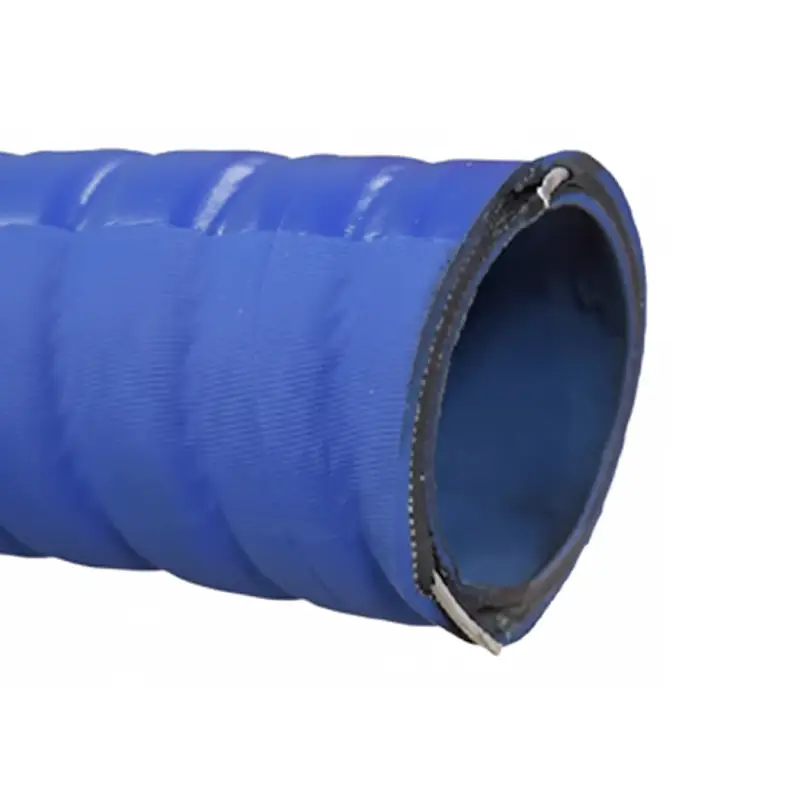

Reinforcement Layer: The reinforcement layer is typically constructed from braided or spiral steel wires, polyester, or synthetic fibers, providing strength, flexibility, and pressure resistance while maintaining the hose’s shape and safety during heavy-duty operations.

Outer Cover: The outer cover is made from durable, weather-resistant, and chemical-resistant materials like synthetic rubber or thermoplastics, protecting the hose from abrasion, environmental factors, and mechanical wear while ensuring long-term operational reliability.

Conductive Elements: Embedded conductive wires or layers within the hose structure safely dissipate static electricity, preventing sparks, fire hazards, or explosions during the transfer of flammable liquids or sensitive chemicals.

Optional Coatings: Some conductive hoses include specialized coatings for enhanced chemical resistance, UV protection, or temperature tolerance, ensuring safe and consistent performance in extreme industrial environments.