Upgrading from 1/4″ to 3/8″ hose gives you better flow and stronger performance. You notice your tools work faster and more efficiently. Pressure drop becomes less of an issue, so your machines run smoother.

This upgrade fits well with heavy-duty jobs in construction, agriculture, and industrial settings. You get reliable operation and more consistent results every time you use your equipment.

How Diameter Affects Flow

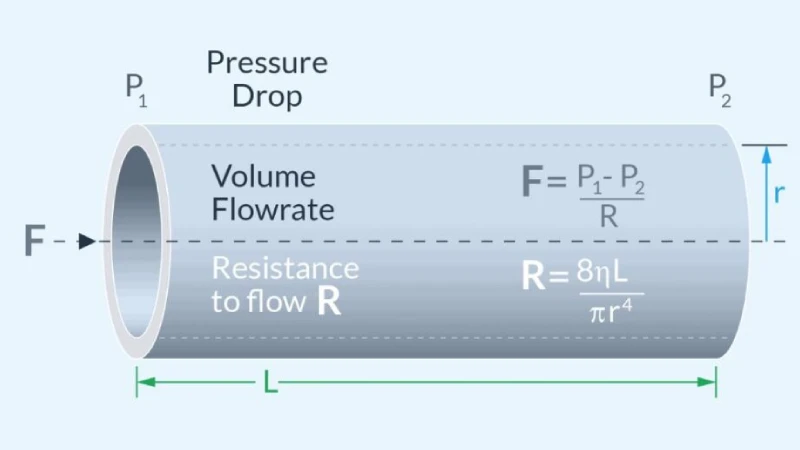

You might wonder why hose diameter matters so much. The answer lies in basic fluid dynamics. When you use a hose with a larger diameter, you increase the cross-sectional area. This change allows more fluid or air to pass through at once. The relationship between diameter and flow rate is not just linear.

In fact, the flow rate increases dramatically as the diameter grows. For example, doubling the diameter can boost the flow rate by up to sixteen times, thanks to the fourth-power relationship in the formula.

Here are some key points about how diameter affects flow:

- The diameter controls the cross-sectional area, which determines how much fluid can move through.

- A smaller hose forces the fluid to travel faster to maintain the same flow rate.

- Larger hoses reduce resistance, so you get less pressure drop and smoother operation.

You can see these principles in the following table:

| Formula | Description |

|---|---|

| Q = π(P₁ – P₂)r⁴ / 8μL | Shows how flow rate depends on pressure difference, radius, viscosity, and length. The radius has a big impact. |

| Q = A × v | Connects flow rate to area and velocity. Bigger area means more flow. |

| A₁v₁ = A₂v₂ | Explains that flow rate stays constant, but velocity changes with area. |

1/4″ vs 3/8″ Hose Performance

When you compare 1/4″ and 3/8″ hoses, you see clear differences in real-world use. A 1/4″ hose works well for low-flow systems and small air tools. If you use pneumatic tools that need only 1-3 CFM, a 1/4″ hose is usually enough. However, if you need more power or run longer hoses, you benefit from upgrading from 1/4″ to 3/8″ hose.

- 3/8″ hoses handle higher flow rates, making them ideal for demanding jobs in construction, agriculture, and industry.

- Longer hose runs with 3/8″ diameter allow oil or air to move back quickly, improving tool retraction and overall speed.

- Larger hoses help prevent pressure drops, so your tools work at full efficiency.

- Restricting airflow with a small hose can lead to poor performance and higher energy costs.

Most hoses are flexible, strong, and kink-resistant, but the size you choose directly affects how well your system works. If you want better flow and smoother operation, consider upgrading from 1/4″ to 3/8″ hose for your next project.

Benefits of Upgrading from 1/4″ to 3/8″ Hose

Increased Tool Efficiency

When you switch to a larger hose, your tools receive the air or fluid they need to perform at their best. Many pneumatic and hydraulic tools require a higher cubic feet per minute (CFM) flow to operate efficiently. A 1/4 inch hose often limits this flow, which can slow down your work and reduce tool power. Upgrading from 1/4″ to 3/8″ hose allows a greater volume of air or fluid to pass through. This means your impact wrenches, grinders, and other high-demand tools run at full strength.

You notice faster response times and more consistent performance, especially when using multiple tools or working with heavy-duty equipment.

If you use tools that demand higher airflow, a 3/8 inch hose helps you avoid frustrating slowdowns and keeps your projects on track.

Reduced Pressure Drop

Pressure drop happens when air or fluid loses force as it travels through a hose. A smaller diameter hose increases resistance, which leads to more pressure loss. When you choose a 3/8 inch hose, you reduce this resistance. Your tools receive steady pressure, so you get reliable results every time you pull the trigger.

This upgrade becomes even more important if you use long hose runs or work in environments where consistent power matters. You spend less time adjusting regulators and more time getting the job done.

Faster Job Completion

You want to finish your tasks quickly and efficiently. Upgrading from 1/4″ to 3/8″ hose helps you achieve this goal. With better flow and less pressure drop, your tools operate at their designed speed. You do not have to wait for air to catch up or deal with sluggish tool performance. This improvement saves you valuable time on each project.

In busy settings like construction sites, farms, or factories, these time savings add up. You complete more work in less time, which boosts your productivity and keeps your schedule on track.

Lower Heat and Smoother Operation

A larger hose diameter does more than just improve flow. It also helps your system run cooler and smoother. When you use a 3/8 inch hose, you increase airflow capacity. This change prevents overheating in both hydraulic and pneumatic systems. You also reduce pressure loss, which means your tools receive a steady supply of air or fluid. This consistency leads to smoother operation and less vibration. By minimizing mechanical stress, you extend the life of your tools and equipment.

- Enhanced airflow capacity keeps systems cool and prevents overheating.

- Reduced pressure loss ensures tools receive a steady volume of air or fluid.

- Lower mechanical stress improves tool performance and longevity.

Where the Upgrade Matters Most

You see the biggest benefits of upgrading from 1/4″ to 3/8″ hose in demanding environments. Construction crews rely on powerful pneumatic tools that need steady airflow. Farmers use hydraulic systems that must run smoothly all day. Industrial workers depend on reliable hoses for assembly lines and heavy machinery.

In these settings, the right hose size makes a noticeable difference. You get more done, experience fewer breakdowns, and enjoy a safer, more efficient workplace.

Choosing the right hose is a smart investment in your tools, your time, and your results.

Upfront Costs and Long-Term Savings

You may notice a higher initial price when you choose a 3/8 inch hose over a 1/4 inch hose. The larger size uses more material and often requires stronger fittings. However, the long-term savings can outweigh the upfront cost.

You spend less on repairs because a larger hose reduces stress on your tools and system. You also cut down on maintenance costs. When you select the right hose length for each task, you avoid unnecessary wear and tear. Over time, these factors help you save money and keep your equipment running smoothly.

- Lower maintenance expenses

- Fewer repairs and replacements

- Better fit for each job with tailored hose lengths

Productivity and Tool Longevity

A 3/8 inch hose lets your tools work at their full potential. You finish jobs faster because your tools receive the flow they need. This boost in productivity means you can take on more projects or complete tasks ahead of schedule.

Your tools also last longer. Less strain and lower heat mean fewer breakdowns. You spend less time fixing equipment and more time working. This improvement in tool life adds value to your investment.

When the Upgrade Makes Sense

Upgrading from 1/4″ to 3/8″ hose makes sense if you use high-demand tools or work in busy environments. If you notice slowdowns, pressure drops, or frequent maintenance, a larger hose can solve these problems. You see the biggest benefits in construction, agriculture, and industrial settings. If you want better performance and lower costs over time, this upgrade is a smart choice.

Considerations Before Upgrading

System Compatibility and Fittings

Before switching to a 3/8-inch hose, check your system for compatibility. Not all tools and machines accept larger hoses. You should look at the fittings on your equipment. Most air tools use 1/4 inch NPT inlets. Both 1/4 inch and 3/8 inch hoses can use 1/4 inch fittings, but the larger hose moves more air or fluid.

This means you get better performance, especially for high-volume jobs. However, quick disconnects can sometimes limit flow, so you want to make sure all parts match your needs.

- 3/8 inch hoses can use 1/4 inch fittings, but you get the best results with fittings that match your hose size.

- JIC and NPT fittings are common choices. Always check for leaks after installation.

- Short 1/4 inch fittings on a 3/8 inch hose do not block flow much, but longer runs or mismatched fittings can cause problems.

Tip: Always inspect your system for leaks after changing hoses or fittings. Even a small leak can reduce performance.

Space, Weight, and Flexibility

You should also think about the space where you use your hose. A 3/8 inch hose is thicker and heavier than a 1/4 inch hose. If you work in tight spaces or need to move your hose often, the extra weight can make a difference. Smaller hoses bend more easily and take up less room. For jobs that require a lot of movement or where space is limited, a 1/4 inch hose might be easier to handle.

When to Stick with 1/4″ Hose

Sometimes, a 1/4 inch hose is the better choice. If your tools only need 1-3 CFM, a larger hose does not add value. In fact, using a 3/8 inch hose for small tools can make your setup more complicated and less efficient. You should match the hose size to your tool’s needs. For light-duty tasks, a 1/4 inch hose works well and keeps your system simple.

Common Mistakes to Avoid

Many people forget to check fitting sizes or skip leak tests after upgrading. You should always:

- Match your hose and fittings for the best flow.

- Test your system for leaks before regular use.

- Avoid using a larger hose when a smaller one will do the job.

Note: The right hose size and fittings help you get the most from your tools and keep your system running smoothly.

How to Upgrade to a 3/8″ Hose

Choosing the best 3/8 inch hose starts with understanding your needs. You should consider the application, pressure, temperature, and the type of fluid or air you plan to move. Use the table below to compare important criteria:

| Criteria | Description |

|---|---|

| Size | Choose the right diameter and length for your job. |

| Temperature | Check the temperature range for safe operation. |

| Application | Match the hose to automotive, industrial, or agricultural use. |

| Material | Select materials for durability and flexibility. |

| Pressure | Ensure the hose handles your system’s maximum pressure. |

| Ends | Pick fittings that match your equipment. |

| Delivery | Confirm the hose supports your required flow rate. |

For example, in automotive work, you power pneumatic tools. In manufacturing, you run air-powered machines. Construction jobs often need hoses for spray painting or heavy equipment.

Choosing Fittings and Accessories

You need the right fittings and accessories for a leak-free setup. Quick connect adapters make switching tools easy. Look for fittings with a ball lock design for a secure seal. Always match the hose diameter and threading with your fittings. If you use pressure washers, check that your hose connects easily to guns, wands, and nozzles. Adapters rated for high pressure help prevent leaks and ensure safety.

Tip: Always verify compatibility between your hose, fittings, and accessories before installation.

Installation and Testing Steps

Follow these steps to upgrade your hose:

- Remove the old hose and inspect all connection points.

- Attach the new 3/8 inch hose using the correct fittings.

- Tighten all connections securely.

- Test the system at low pressure first to check for leaks.

- Gradually increase pressure and monitor for any issues.

- Inspect for leaks and ensure smooth operation.

Why Choose Kingdaflex 3/8 Inch Hydraulic Hose

Kingdaflex 3/8 Inch Hydraulic Hose stands out for quality and reliability. Each hose meets SAE and EN standards and passes hydrostatic testing at 1.5 times the working pressure. You benefit from flexible hose options, strong abrasion resistance, and seamless joint designs that prevent leaks. Kingdaflex offers a wide range of fittings for compatibility with different systems. Rigorous inspections and pressure tests ensure safety and performance. Bulk pricing and professional assembly services add value for both small and large projects.

| Feature/Benefit | Description |

|---|---|

| Hydrostatic Testing | Verifies hose strength and safety. |

| Flexibility & Bend Radius | Makes installation easier in tight spaces. |

| Abrasion Resistance | Protects against wear in tough environments. |

| Leakage Prevention | Ensures secure, leak-free connections. |

| Standards Compliance | Meets SAE and EN requirements for high-pressure systems. |

Choose Kingdaflex for a dependable upgrade that supports your equipment and keeps your operations running smoothly.

Upgrading from a 1/4″ to a 3/8″ hose gives you better flow, less risk of damage, and faster job completion. Experts point out these main reasons:

| Reason for Upgrade | Description |

|---|---|

| Improved Flow | Larger diameter moves more fluid or air for better performance. |

| Reduced Risk of Damage | Thicker hoses resist getting caught or damaged during use. |

| Enhanced Efficiency | Higher flow and pressure help you finish tasks quickly and cleanly. |

Before you upgrade, check your system’s pressure rating, fluid compatibility, and space. Choosing a high-quality hose like Kingdaflex ensures reliable performance and long-lasting value. If you want smoother operation and better results, now is the time to make the switch.