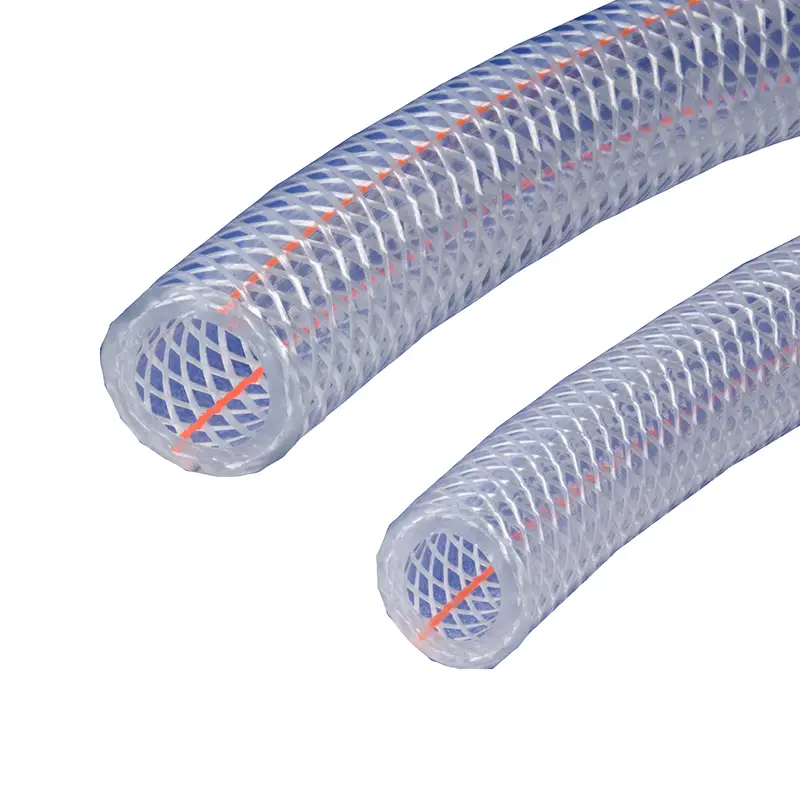

We offer premium braided chemical hoses, specifically engineered with textile or wire reinforcement to deliver superior pressure resistance and structural integrity. Our braided construction is essential for safely transferring aggressive chemicals, solvents, and acids in high-demand, high-pressure environments. These hoses combine a chemically inert inner liner with robust external reinforcement. This design guarantees reliability, prevents kinking under suction, and ensures maximum service life and operational safety during critical fluid transfer applications.

High Working Pressure The internal braiding significantly increases burst strength. This allows for safe operation at higher pressures common in industrial processing lines.

Enhanced Structural Integrity Braiding prevents hose expansion and kinking. It ensures a stable, consistent flow path, which is critical for accurate transfer and pump protection.

Chemically Resistant Liners We integrate liners like PTFE and UHMWPE. These materials ensure inertness, protecting the reinforcement and media purity from chemical attack.

Excellent Flexibility Despite the reinforcement, the braiding allows for necessary movement. This provides a flexible connection essential for dynamic or vibrating equipment.

We focus on engineering multi-layered hoses with textile or wire reinforcement. This construction delivers high pressure ratings and superior durability for safe transfer of corrosive acids and solvents. We offer reliable, cost-effective solutions tailored for global industrial chemical applications.

High Pressure Capability The textile or wire braid acts as a robust reinforcement. This significantly increases the hose’s maximum working pressure and improves overall safety margins.

Superior Kink Resistance The braided structure maintains the hose’s circular shape. This prevents the hose from collapsing or kinking, ensuring consistent, uninterrupted fluid flow.

Reduced Hose Expansion Braiding limits the radial expansion of the hose walls under pressure. This is vital for maintaining dimensional stability and reliable volumetric transfer.

Increased Service Life The strong reinforcement protects the inner liner from damage caused by pressure spikes and external stress. This construction leads to much longer hose durability.

High-Pressure Injection Systems Used to accurately inject concentrated chemicals into pipelines or vessels. The braiding handles the high pressure spikes without expanding or risking a rupture.

Loading/Unloading High-Viscosity Fluids Essential for transferring thick or heavy chemicals at elevated pressures. The robust structure prevents collapse or excessive kinking under heavy flow dynamics.

Steam and Hot Chemical Transfer Some braided hoses are rated for high-temperature steam and hot chemicals. The reinforcement maintains structural integrity against thermal expansion and pressure.

Dynamic Industrial Connections Serves as flexible links on vibrating or mobile equipment where movement occurs. The braiding ensures the connection remains stable and secure under constant flexing.

We can produce custom braided chemical hoses featuring specialized liners like PTFE or UHMWPE, reinforced with high-strength textile or steel wire. Our manufacturing process ensures superior burst pressure ratings and excellent flexibility for safely transferring corrosive media and solvents in challenging industrial environments globally.

We offer high-pressure braided chemical hoses complete with securely crimped, chemically resistant fittings. Our robust, multi-layered construction features high-tensile reinforcement to safely handle elevated pressures and aggressive media like concentrated acids and solvents, providing a reliable, ready-to-use assembly for critical industrial applications.

We offer premium stainless steel braided chemical hoses, featuring exceptional corrosion resistance and high-pressure capabilities. The metal braid provides superior protection against kinking, abrasion, and external damage, while the inner PTFE or UHMWPE liner ensures chemical inertness. This assembly is ideal for maximum safety and durability in aggressive chemical transfer applications.

We offer specialized heated high pressure braided chemical hoses, engineered with high-strength reinforcement and PTFE or PFA liners. These hoses safely handle corrosive chemicals at elevated temperatures and pressures. Our integrated heating solutions prevent crystallization or maintain viscosity, ensuring efficient and continuous fluid transfer in critical applications.

We offer premium chemical braided pressure hose solutions designed for the safe and efficient transfer of aggressive industrial fluids. Featuring robust textile or steel reinforcement, our hoses withstand high working pressures and maintain flexibility. We ensure exceptional resistance to corrosion and provide customizable compounds for specific chemical compatibility and operational demands.

We offer premium PTFE lined chemical resistant braided hose solutions, engineered for the safe transfer of aggressive fluids. The inert PTFE core provides exceptional chemical compatibility across nearly all industrial media. Reinforced with durable stainless steel braiding, our hoses deliver superior pressure resistance and flexibility for critical chemical processing and transfer applications.

We offer customized braided chemical hoses engineered for safe transfer of highly aggressive fluids. Our hoses feature multi-ply textile or steel braid reinforcement and chemical-resistant linings tailored to specific media. We ensure superior pressure handling, temperature stability, and complete material compatibility for reliable, leak-proof industrial operation.

We offer premium chemical rubber hoses engineered for the safe and efficient transfer of various aggressive media, including acids, solvents, and alkalis. Featuring high-grade chemical-resistant liners (like UHMWPE) and robust construction, our hoses provide maximum durability and reliability, ensuring compliance with strict industrial safety standards for demanding processes.

We offer premium rubber chemical transfer hoses designed for safe and efficient handling of diverse aggressive media, including acids, solvents, and alkalis. Featuring specialized chemical-resistant liners and robust construction, our hoses provide maximum flexibility, durability, and safety for industrial and processing applications, minimizing risk and downtime.

We offer high-performance chemical resistant hoses engineered for the safe and efficient transfer of a vast range of aggressive materials, including acids, solvents, and corrosives. Our hoses feature premium liners for superior protection and durability. Built for demanding industrial applications, they ensure maximum safety and extended service life while meeting stringent industry standards.

Customizing your braided chemical hoses is vital for optimizing safety, pressure handling, and service life in your most demanding fluid transfer tasks. Since these hoses often operate under high pressure with corrosive media, tailored specifications prevent structural failure and ensure precise media compatibility.

We customize the reinforcement by specifying the material (e.g., high-tensile polyester or steel wire) and the braid angle/density. This directly controls the hose’s maximum working pressure and its resistance to kinking and crushing, tailoring the structural integrity to your system’s exact pressure demands.

We select the inner liner material from options like PTFE, UHMWPE, or specialized elastomers, based on the full chemical profile and temperature of your media. This is the first line of defense; we ensure its compatibility prevents swelling, degradation, or permeation by the specific corrosive substance being transferred.

We offer specialized outer cover compounds formulated to resist external hazards, including severe abrasion, prolonged UV exposure, and accidental chemical splash. This customized cover protects the vital internal braid reinforcement layers, significantly extending the hose’s functional life in harsh industrial environments.

We install permanently crimped end fittings, using chemically resistant alloys like stainless steel, chosen for compatibility with the media and high pressure. We ensure the connection integrity is flawless, eliminating the most common point of failure and guaranteeing a secure, leak-proof assembly for maximum safety.

A braided chemical hose is a heavy-duty, multi-layered flexible conduit specifically engineered for the safe and reliable transfer of aggressive, corrosive, or high-purity chemicals under high pressure or challenging dynamic conditions. Its defining feature is one or more layers of woven reinforcement, known as braiding, which is typically constructed from high-tensile textile fibers or stainless steel wire, located between the inner chemical-resistant liner and the outer protective cover.

This braiding provides the essential structural strength to handle significant internal pressure, resist external crushing, and prevent the hose from kinking or collapsing under full vacuum. Combined with a chemically inert liner (such as PTFE or UHMWPE), the braided chemical hose offers a durable, high-performance solution critical for industrial processes like chemical loading/unloading, steam transfer, and high-pressure injection systems, where safety and hose longevity are paramount.

A braided chemical hose is used in applications that require the safe transfer of corrosive media combined with the need to withstand high operating pressures or full vacuum conditions. Its reinforced construction ensures structural integrity, preventing catastrophic failure, kinking, and collapse, which is essential for maintaining continuous flow and safety compliance.

These hoses are indispensable across industries like refining, heavy manufacturing, and specialized chemical processing. They provide flexible, reliable connections in fixed piping systems or dynamic environments, ensuring the secure handling of aggressive acids, volatile solvents, and hot chemicals during demanding operations.

High-Pressure Chemical Injection Used in systems that inject precise amounts of concentrated chemicals into a pressurized pipeline or reactor vessel. The wire or textile braiding handles the intense pressure spikes generated by injection pumps without expanding or rupturing, ensuring continuous and accurate dosing.

Bulk Loading and Off-Loading Essential for transferring large volumes of corrosive media to or from tanker trucks, railcars, and storage tanks. The robust braiding provides crush resistance and durability against the heavy forces of continuous handling, flow surges, and dynamic movement at terminals.

Hot Chemical and Steam Transfer Specific braided hoses are engineered to safely convey hot, corrosive liquids and saturated steam. The reinforcement maintains the hose’s structural integrity against the high temperatures and pressures, preventing thermal expansion and potential blowout of the hose assembly.

Vacuum Suction Service Used to draw or suck chemicals out of vessels or storage containers. The internal helical wire reinforcement, combined with the braid, prevents the hose from collapsing inward under the high negative pressure (full vacuum) generated by suction pumps.

Choosing Kingdaflex braided chemical hoses guarantees a robust, high-performance solution for transferring corrosive media under high-pressure demands. Our specialized multi-layer design, incorporating premium textile or wire braiding, ensures superior burst strength, flexibility, and unmatched safety in dynamic industrial applications.

We commit to engineering hoses that exceed international safety standards while providing maximum resistance to chemical degradation and abrasion. Kingdaflex delivers durable, reliable assemblies that significantly reduce the risk of critical failure and minimize operational downtime in your hazardous fluid conveyance systems.

Supreme Pressure Rating Our hoses feature high-density textile or steel wire braiding, specifically engineered to achieve superior working and burst pressure ratings. This reinforcement allows for the safe handling of high-pressure fluid transfer and protects against surges or spikes inherent in pumping systems.

Chemically Inert Liners Kingdaflex utilizes specialized liners like PTFE and UHMWPE that are non-reactive with virtually all corrosive acids and solvents. This ensures the integrity of both the hose structure and the transferred chemical, preventing swelling, degradation, and contamination.

Exceptional Durability and Abrasion Resistance The heavy-duty cover and robust braiding provide outstanding resistance to external crushing, kinking, and environmental abrasion. This structural resilience ensures a long service life, even when the hose is subject to frequent dragging and rough handling on the plant floor.

Customization for Vacuum Service We offer specialized construction incorporating a helical wire, alongside the braiding, to handle full vacuum conditions without collapsing. This customization ensures reliability in critical suction and transfer applications, eliminating flow interruptions caused by hose deformation.