We offer chemical delivery hoses designed to ensure safe, efficient, and reliable transfer of a wide range of industrial chemicals. Our hoses are engineered for durability, flexibility, and resistance to harsh chemical environments, making them suitable for factories, plants, and specialized applications requiring consistent performance and safety compliance.

Durable Construction: Built with high-strength materials, our chemical delivery hoses resist abrasion, corrosion, and harsh chemical exposure, ensuring long-lasting performance even in demanding industrial environments.

Flexible Design: These hoses provide excellent flexibility, allowing easy handling, installation, and maneuvering around tight spaces without compromising chemical flow efficiency or structural integrity.

Chemical Resistance: Engineered to withstand acids, solvents, and other aggressive chemicals, our hoses maintain reliability and safety for continuous operations in diverse industrial applications.

High-Pressure Capability: Designed to endure high-pressure applications, our chemical hoses ensure safe transfer of fluids, minimizing the risk of leaks or ruptures during critical processes.

Customizable Options: We offer hoses in various lengths, diameters, and materials, allowing customization to meet specific operational needs and industry standards efficiently.

As a reliable chemical delivery hose manufacturer from China, we specialize in producing durable, flexible, and chemically resistant hoses for diverse industrial applications. Our hoses ensure safe and efficient transfer of acids, solvents, and other aggressive chemicals. With customizable options, high-pressure capability, and strict quality control, we provide reliable solutions that meet international standards and your specific operational needs.

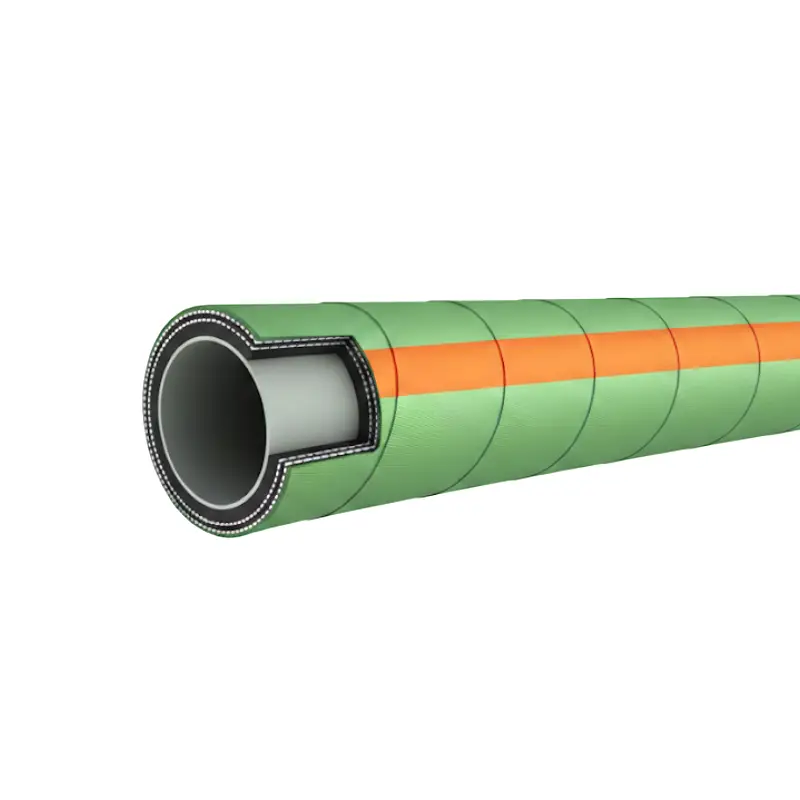

Inner Tube: Made from chemically resistant materials, the inner tube safely carries acids, solvents, and other aggressive chemicals, preventing contamination and ensuring consistent flow during industrial operations.

Reinforcement Layer: Constructed with braided or spiraled fibers or steel wire, this layer provides strength, pressure resistance, and durability while maintaining flexibility for easy handling and installation.

Cover Layer: The outer cover protects against abrasion, weather, and chemical exposure, extending hose life while ensuring safe operation in demanding environments and harsh conditions.

Chemical Plants: Used for transferring acids, solvents, and other aggressive chemicals safely within chemical production facilities, ensuring smooth operations while protecting workers and equipment from hazardous exposure.

Petrochemical Industry: Essential for handling fuels, oils, and chemical additives, these hoses withstand corrosive materials and high temperatures, maintaining operational safety and efficiency in complex processes.

Pharmaceutical Manufacturing: Applied in precise chemical transfers during drug production, ensuring contamination-free handling, high hygiene standards, and consistent delivery of critical ingredients within controlled environments.

Food and Beverage Industry: Safe for transferring food-grade chemicals and cleaning agents, maintaining hygiene standards, and ensuring regulatory compliance during production, processing, and cleaning operations.

Water Treatment Facilities: Used for chemical dosing, neutralization, and cleaning processes, ensuring safe handling of corrosive or reactive substances while maintaining system efficiency and worker safety.

We manufacture all chemical delivery hoses to meet diverse industrial needs, combining durability, flexibility, and chemical resistance. Our hoses are designed for safe, efficient transfer of acids, solvents, and other aggressive chemicals. With strict quality control and customizable options, we provide reliable solutions for every application.

We offer chemical suction and delivery hoses designed for safe and efficient transfer of a wide range of chemicals. Built for flexibility and chemical resistance, our hoses are suitable for industrial, laboratory, and manufacturing applications. We provide various sizes and materials to meet different operational needs and ensure reliable chemical handling.

We offer chemical delivery food hoses designed for safe transfer of food-grade chemicals, cleaning agents, and additives. These hoses provide excellent chemical resistance, flexibility, and durability for use in food processing, beverage production, and other sanitary applications. We supply hoses in various sizes and lengths to meet different operational requirements efficiently.

We offer custom chemical delivery and suction hoses designed to meet specific industrial requirements. Our hoses provide reliable chemical resistance, flexibility, and durability for transferring a wide range of chemicals. Available in various sizes, materials, and lengths, we supply solutions that ensure safe, efficient handling and smooth operations across diverse applications.

We offer UHMWPE chemical hoses designed for extreme chemical resistance and flexibility. Our hoses feature ultra‑high‑molecular‑weight polyethylene liners that handle acids, solvents, and abrasive slurries. Reinforced with textile braids or steel helix, they are lightweight yet durable, perfect for industrial pump or tank‑truck applications, ensuring safe and efficient chemical transfer in demanding environments.

We provide XLPE chemical hoses that balance chemical resistance, flexibility, and cost efficiency. Constructed with cross‑linked polyethylene inner linings, these hoses handle fuels, alcohols, and many industrial chemicals. Ideal for general suction and discharge applications, they are reinforced for durability, offering smooth flow and reliability, making them suitable for everyday chemical delivery tasks in various industries.

We provide PTFE chemical hoses featuring a polytetrafluoroethylene inner lining for superior chemical inertness and high-temperature tolerance. These hoses resist corrosive chemicals, solvents, and reactive substances, making them ideal for pharmaceutical, food, or ultra‑clean industrial applications. Flexible yet durable, they ensure smooth chemical transfer while maintaining purity and preventing contamination in sensitive processes.

We understand that every industrial application has unique requirements, so we offer fully customizable chemical delivery hoses to meet your specific needs. From size and material selection to pressure ratings and length, we ensure your hoses provide safe, efficient, and reliable chemical transfer tailored to your operations. Our expert team works closely with you to deliver solutions that perform in even the most demanding environments.

We help you choose the right inner tube and cover materials based on the chemicals being transferred, ensuring optimal resistance, durability, and operational safety for your specific applications.

We offer hoses in a variety of diameters and lengths, allowing you to achieve the perfect fit for flow rate requirements, installation space, and operational efficiency.

We design hoses to withstand the pressure and temperature conditions of your process, ensuring reliable performance, preventing leaks, and maintaining safety in all operating environments.

We offer color coding and marking options to help you easily identify hoses for different chemicals, improving safety, operational efficiency, and compliance with industrial standards.

A chemical delivery hose is a specialized industrial hose designed to safely transport a wide range of chemicals, including acids, solvents, and other corrosive or aggressive fluids. It is engineered to resist chemical corrosion, high pressure, and temperature variations, ensuring safe and efficient transfer in industrial, manufacturing, or laboratory settings.

These hoses typically consist of three main components:

Inner Tube: Made from chemical-resistant materials to carry fluids without reacting or degrading.

Reinforcement Layer: Provides strength and pressure resistance, often using braided fibers or steel wire.

Outer Cover: Protects the hose from abrasion, chemicals, and environmental factors.

Chemical delivery hoses are widely used in chemical plants, pharmaceutical manufacturing, petrochemical industries, water treatment, and other industrial applications where safe chemical transfer is critical.

Chemical delivery hoses are essential in many industries, designed to safely transfer aggressive or hazardous chemicals without risk of leaks, contamination, or equipment damage.

Transferring Acids and Solvents: Used for moving corrosive liquids in chemical plants and factories, these hoses ensure safe handling while preventing leaks, spills, or contamination during industrial operations.

Pharmaceutical Production: Applied in precise transfer of sensitive chemical ingredients, these hoses maintain hygiene standards, prevent cross-contamination, and support accurate dosing in drug and medicine manufacturing processes.

Petrochemical Applications: Used for transferring fuels, oils, and chemical additives, these hoses withstand harsh environments and ensure operational efficiency in demanding petrochemical production and processing plants.

Food and Beverage Processing: Utilized for safe handling of cleaning agents and food-grade chemicals, ensuring hygiene compliance and reliable sanitation processes during production, packaging, and facility maintenance operations.

Water Treatment Plants: Used to handle chemicals for disinfection, neutralization, or purification processes, ensuring safe operations and protecting both workers and equipment from harmful chemical exposure.

Chemical hoses are engineered to handle a wide variety of fluids safely and efficiently. Their inner lining, reinforcement, and outer cover determine chemical compatibility, temperature range, and pressure resistance. Choosing the right hose ensures safe delivery of chemicals, acids, alkalis, fuels, and other industrial liquids without leaks or contamination.

Acids (Sulfuric, Hydrochloric, Nitric, etc.) – We provide hoses suitable for strong and weak acids, offering excellent chemical resistance and preventing corrosion. These hoses ensure safe handling, maintain flow efficiency, and reduce the risk of leaks or hazardous reactions, making them ideal for industrial, laboratory, and chemical processing applications.

Alkalis and Caustic Solutions – We offer hoses capable of delivering caustic solutions like sodium hydroxide or potassium hydroxide. Their durable inner lining resists chemical degradation, ensuring long-term performance, safe transfer, and reliability in manufacturing, cleaning, and chemical industries where high-concentration alkalis are handled efficiently.

Solvents and Organic Chemicals – We provide hoses designed for transporting flammable or corrosive solvents, including alcohols, ketones, and esters. These hoses resist swelling, chemical attack, and degradation. They ensure safe delivery, maintain chemical purity, and minimize environmental hazards during transfer in industrial, laboratory, and pharmaceutical operations.

Petroleum Products and Fuels – We offer hoses engineered for fuels such as gasoline, diesel, kerosene, and lubricants. Their chemical-resistant inner lining prevents permeation and degradation. Designed for safe fuel transfer in industrial, automotive, and marine applications, these hoses provide durability, leak prevention, and resistance to heat, pressure, and environmental exposure.

Food-Grade and Pharmaceutical Liquids – We provide hoses suitable for delivering food or pharmaceutical liquids, maintaining purity and hygiene. Constructed with FDA-compliant materials, they resist chemical interaction and contamination. Perfect for oils, syrups, and sensitive chemicals, these hoses ensure safe transfer without compromising quality or safety in the food and pharmaceutical industries.

Installing chemical delivery hoses requires careful attention to ensure safe, reliable, and efficient operation. Proper installation helps prevent leaks, damage, and safety hazards while maximizing hose performance and service life in demanding chemical handling applications.

Inspect the Hose and Fittings: Before installation, we carefully examine the hose and fittings for visible damage, defects, or wear, ensuring they meet specifications and safety standards before being put into service.

Choose Proper Connections: We match the hose with the correct couplings and fittings, ensuring compatibility with the chemical being transferred, preventing leaks, and avoiding potential risks from chemical reactions or pressure issues.

Position the Hose Correctly: We place the hose to avoid twisting, sharp bends, or kinks that could restrict flow or damage the hose, ensuring smooth, efficient chemical transfer and safe operation.

Secure the Hose Assembly: We tighten and secure clamps, couplings, or connections properly, ensuring the hose stays firmly in place during use, minimizing risks of disconnection, spills, or leaks under operating conditions.

Test Before Full Operation: We perform a pressure and leakage test after installation, confirming the hose is functioning properly, capable of handling required chemicals, and safe for long-term continuous use.

Choosing the right chemical delivery hose is vital for safe and efficient operations. At Kingdaflex, we provide solutions designed to meet industrial demands, ensuring reliability, performance, and safety in every application. Our hoses are engineered with precision to support your chemical transfer needs effectively.

Reliable Performance: We manufacture hoses built to withstand aggressive chemicals, pressure, and demanding environments, ensuring consistent, safe operation that reduces downtime and maintains efficiency for industrial processes.

Customizable Solutions: We offer hoses in various materials, diameters, and lengths with optional features like anti-static linings or fittings, allowing you to get hoses tailored to your exact needs.

Durability and Safety: We design hoses with reinforced layers and protective covers, providing strong resistance against abrasion, weathering, and chemical exposure while ensuring safety in hazardous environments.

Global Supply Capability: We supply hoses worldwide, offering dependable delivery schedules, professional support, and industry expertise to meet the needs of customers in diverse markets and applications.

Expert Support: We provide guidance from selection to installation, helping you choose the best hoses for your application while ensuring compliance with industrial safety standards and requirements.