Discover unmatched durability and precision with our Drain Fitting Plug. Expertly crafted with high-grade steel, this threaded plug guarantees a secure fit, ensuring leak-free performance. Engineered with precision in mind, our steel plug is the epitome of reliability, providing a robust solution for your plumbing needs. Head Pipe Fitting Plug – the perfect fusion of strength and craftsmanship.

Material:304 Stainless Steel

Thread: 1/16″,1/8“,1/4″, 3/8″, 1/2″, 3/4″,1″ BSPP Male Thread

When selecting drain plug fittings, it’s essential to consider various features that contribute to their functionality and effectiveness.

Here is a list of product features related to drain plug fittings:

Material Composition:

Specify the material used for the drain plug fitting (e.g., stainless steel, brass, aluminum) to indicate durability and corrosion resistance.

Thread Size and Type:

Clearly state the thread size and type (e.g., NPT, BSP) to ensure compatibility with the corresponding drain or receptacle.

Sealing Mechanism:

Describe the sealing mechanism (e.g., O-ring, gasket) to highlight leak prevention and ensure a secure fit.

Magnetic Properties:

Mention if the drain plug fitting includes magnetic properties to attract and capture metallic debris or particles in the fluid.

Installation Type:

Specify whether it is a screw-in type, push-in type, or other installation methods, providing guidance on how to install the fitting properly.

Head Type:

Indicate the type of head (e.g., hex head, square head) for easy installation and removal using common tools.

Drain Type Compatibility:

Specify the compatibility with different drain types, such as oil drains, transmission drains, or other fluid systems.

Finish:

Describe the finish of the drain plug fitting (e.g., chrome-plated, zinc-plated) for aesthetic appeal and additional corrosion resistance.

Temperature and Pressure Ratings:

Provide information on the temperature and pressure ratings to ensure the fitting can handle the operating conditions of the system.

Ease of Removal:

Highlight features that facilitate easy removal, such as integrated handles or anti-slip designs.

Machining Precision:

Emphasize the precision of machining to ensure a tight and reliable fit, minimizing the risk of leaks.

Compliance with Standards:

State if the drain plug fitting complies with industry standards (e.g., SAE, ISO) to assure users of its quality and performance.

Anti-Corrosion Coating:

Specify if the fitting has an anti-corrosion coating to enhance its resistance to rust and other corrosive elements.

Customization Options:

If applicable, mention any customization options, such as color choices or additional features that users can select.

Packaging and Accessories:

Include information about packaging and any additional accessories provided with the drain plug fitting, such as replacement seals or installation tools.

Environmental Considerations:

Discuss any environmentally friendly features, such as recyclability or compliance with environmental regulations.

Our drain plug fittings are made of 304 stainless steel material, carbon steel to create high strength and durability.

We can customize all drain plugins in different sizes, to be Compatible with all device installation needs. We can provide you with the full catalog for your selection to get your desired drain plugs with the right specifications for your project.

This drain plug is designed with a hexagon head core, used as the thread pipe plug.

Using a drain plug is a straightforward process, and it typically involves securing the plug in place to prevent leaks and allow for controlled drainage. Below are general steps on how to use a drain plug:

Locate the drain opening or port on the system or container from which you need to remove or drain fluid.

Ensure that you have the appropriate drain plug for your application, considering factors such as size, thread type, and material compatibility.

Clear the area around the drain to provide easy access. If necessary, use a rag or absorbent material to catch any spilled fluids.

If the fluid you are draining is hot or hazardous, take appropriate safety measures. Wear protective gear, and make sure the surrounding environment is safe.

If there’s already a drain plug in place, use the appropriate tool (e.g., a wrench or socket) to loosen and remove it. Turn counterclockwise to loosen.

If you are installing a new drain plug or reinserting the existing one, carefully thread the plug into the drain opening. Turn clockwise to tighten.

Start by hand-tightening the drain plug to ensure proper threading without cross-threading. Make sure the plug is snug but not overly tight.

Use a Tool (if necessary):

If additional tightening is needed, use the appropriate tool (e.g., wrench) to securely tighten the drain plug. Be cautious not to overtighten, as this may damage the plug or the threading.

Check for Leaks:

After tightening, visually inspect the area around the drain plug for any signs of leaks. Address any leaks immediately by adjusting the tightness or replacing the plug if necessary.

Dispose of Drained Fluid Properly:

Collect the drained fluid in a suitable container, and dispose of it according to local regulations. Avoid environmental contamination.

Securely Close the System:

If the drain plug is part of a system, ensure that all other components are properly closed and secured before resuming normal operation.

Document the Procedure (if necessary):

In some cases, especially for maintenance or regulatory purposes, document the drain procedure, including the date and any observations made during the process.

Store the Drain Plug (if reusable):

If the drain plug is reusable, store it in a clean and dry place for future use. Ensure it remains in good condition for the next draining operation.

Following these steps will help you effectively use a drain plug while minimizing the risk of leaks and ensuring a safe and controlled drainage process.

Here is manufacturing process to produce a qualified drain plug.

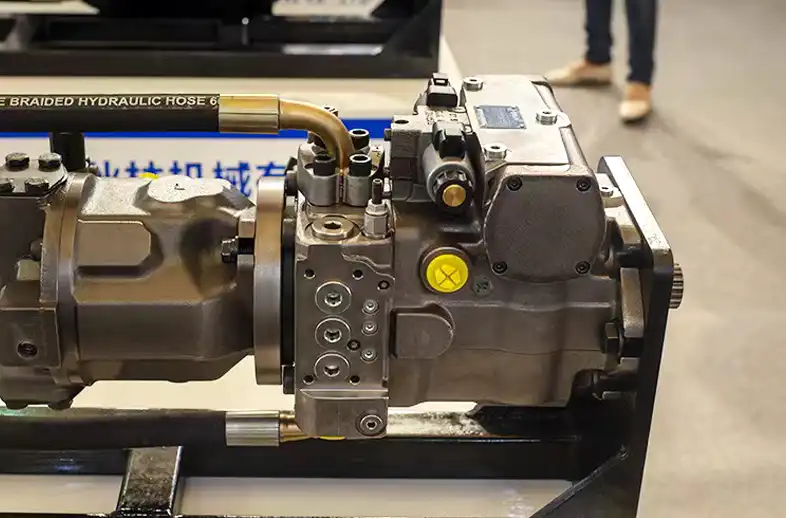

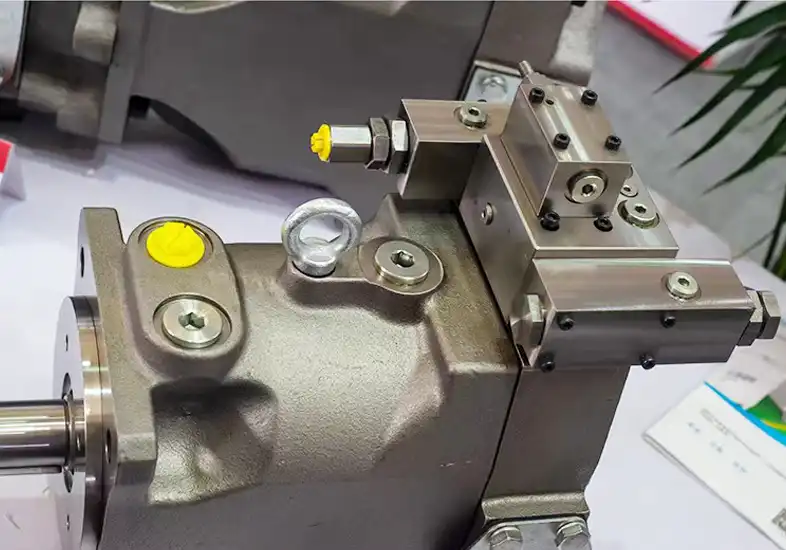

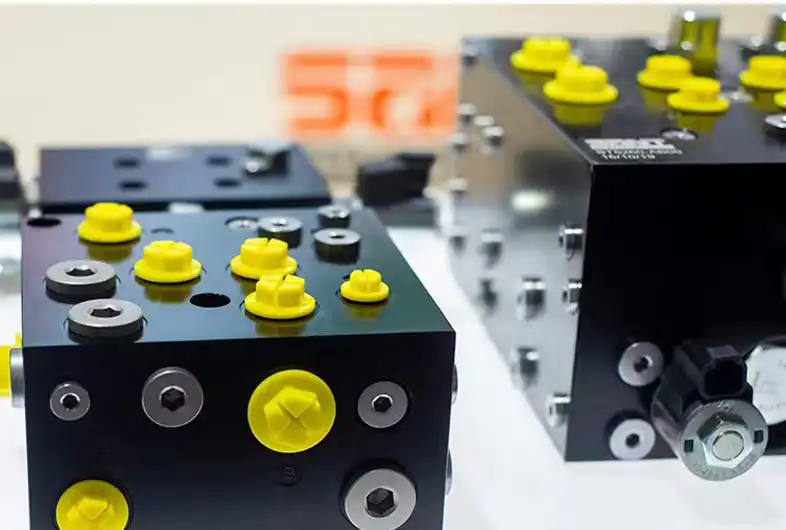

Hexagonal plugs find extensive applications in various fields, including hydraulic transmission, pneumatic systems, engineering machinery, automobile manufacturing, general equipment manufacturing, and more.

They are commonly employed to seal process holes and oil ports in components such as hydraulic oil pumps, hydraulic valves, hydraulic cylinders, hydraulic motors, as well as in reducers and hydraulic stations.

The hexagon plug’s versatility and usage across different sectors highlight its significance in maintaining the integrity and efficient operation of diverse hydraulic and pneumatic systems.

Hexagon drain plugs are unsung heroes in the realm of hydraulic systems. Their design, materials, and sealing capabilities collectively enhance the efficiency and reliability of these systems.

A hexagon drain plug for construction machinery is a specific type of plug used to seal and secure drain openings in various components of construction equipment. Construction machinery, such as excavators, bulldozers, loaders, and other heavy equipment, typically have fluids like oil, hydraulic fluid, or coolant circulating through various parts of their systems.

A hexagon drain plug for a hydraulic pump is a type of plug used to seal the drain port of a hydraulic system. Hydraulic systems use fluid to transmit power, and over time, contaminants or degraded fluid may accumulate in the system.

Our factory is compounded with ISO 9001:2015 standards.

We value quality in all of our processes. We ensure that our hydraulic hoses can withstand the toughest environmental stresses.

The entire production link of our hydraulic hose takes place in our factory, to ensure the quality of each rubber tube, and a 99.99% on-time delivery rate.

If you have special requirements for the performance of rubber hose, you can contact us, we provide a variety of customized services.