Hydraulic systems are the muscle behind countless industrial and mobile applications, from construction equipment to manufacturing machinery. At the heart of these systems are hydraulic hoses, which transport fluid under immense pressure. But with a vast array of hoses available, how do you know which one is right for the job? This is where the hydraulic hose color code comes in.

This guide will demystify the color-coding system used on hydraulic hoses. We’ll explore what each color signifies, from working pressure to fluid compatibility. By understanding these simple visual cues, you can quickly and accurately identify the correct hose, ensuring both the safety of your operations and the longevity of your equipment.

What Is the Hydraulic Hose Color Code?

To strengthen the understanding of the hydraulic system, Joint Industry Conference (JIC) and American National Standards Institute (ANSI) establish the hydraulic hose color code.

The color coding of the hydraulic hose is super helpful for you to identify the hydraulic hose.

Hydraulic hose color codes are typically a combination of stripes or bands of color that indicate the type of fluid inside the hose. These codes can vary from country to country, but generally, the most common colors used include:

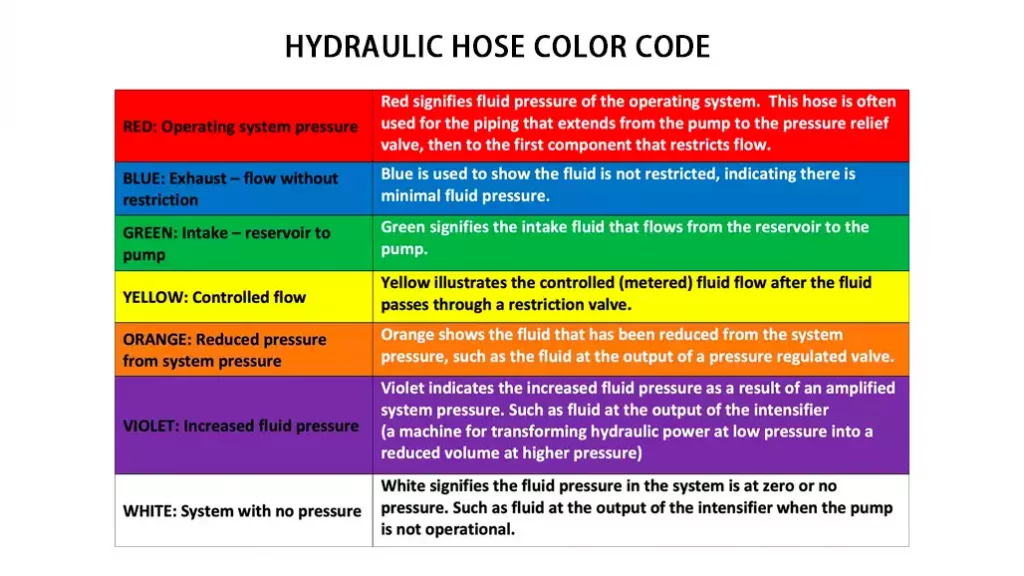

Here is the meaning of the specific hydraulic hose color code:

Red

Often used for the pipe that runs from the pump to the pressure relief valve to the first part that restricts the flow, this symbol denotes the operation system pressure of the fluid.

Blue

The color blue is used to indicate that the fluid is unrestricted and that there is little fluid pressure.

Green

Green signifies the intake of fluid from the reservoir to the pump.

Yellow

Yellow means the controlled fluid flow after it passes through the restriction valve.

Orange

Orange shows the fluids that have been reduced from the system pressure, such as the fluids of pressure regulated valve.

Violet

Violet indicates the increased fluid pressure resulted from the amplified system pressure.

White

White shows the fluid pressure in the system is zero or no pressure.

Hydraulic Hose Color Code chart

| Color | Meaning |

| Red | Indicates operating system pressure or high-pressure lines. |

| Blue | Used for low-pressure return lines, indicating minimal fluid pressure. |

| Green | Signifies the intake of fluid from the reservoir to the pump. |

| Yellow | Illustrates controlled fluid flow after it has passed through a restriction valve. |

| Orange | Shows fluid that has been reduced from the system pressure. |

| Violet | Indicates increased fluid pressure as a result of an amplified system pressure. |

| White | Represents a system with no fluid pressure. |

| Black | The most common color for general purpose hoses. |

It is important to note that these are general guidelines established by organizations like the Joint Industry Conference (JIC) and the American National Standards Institute (ANSI). Specific applications and manufacturers may have their own unique color codes.

What Color Are Hydraulic Lines?

Hydraulic lines are not a single color; they come in a variety of colors and often have color-coded markings to indicate their purpose, pressure rating, or the fluid they carry. While there isn’t one universal standard that applies to all industries, many use a color-coding system to improve safety and simplify maintenance. This system, established by organizations like the Joint Industry Conference (JIC) and American National Standards Institute (ANSI), helps workers quickly identify a line’s function.

Some common colors and their meanings include:

- Red: Typically used for high-pressure lines, signaling a hazard.

- Blue: Often denotes low-pressure return lines, indicating minimal fluid pressure.

- Yellow: May be used for lines carrying specific types of oil or controlled fluid flow.

- Green: Signifies an intake line, carrying fluid from a reservoir to a pump.

- Orange: Indicates fluid with reduced system pressure.

- Violet: Used for increased fluid pressure due to amplification.

What Is the Hydraulic Hose Color Used for?

The hydraulic hose color code is widely used in hydraulic circuit schematics, and the color coding of the hydraulic hose can be printed on the hydraulic hose layline based on the specific pressure ratings, and different hydraulic hoses with different color codes can be used to match the specific requirement.

It is important to note that different industries and applications may have their own unique color codes, so it is always best to consult the manufacturer’s specifications to ensure that you are using the correct color code.

In conclusion, hydraulic hose color codes play an important role in ensuring the safety and efficiency of hydraulic systems. By using the correct color code, operators can quickly and easily identify the contents of a hose and avoid potential hazards.

What Color is Hydraulic Hose Wrap?

Hydraulic hose wrap, also known as a sleeve or guard, is used to protect hoses from abrasion, impacts, and environmental factors. While often available in a standard black color, these protective wraps come in a range of colors, which can be used to further enhance safety and organization within a hydraulic system. These colors are not always tied to a universal code like the hoses themselves, but they can be used for various purposes, such as identifying a group of hoses or marking lines with a specific function.

Common colors for hydraulic hose wraps and their uses include:

- Black: The most common color, offering general-purpose protection and UV resistance.

- Yellow: Often used for high visibility, especially in heavy machinery and construction environments.

- Red: Can be used to highlight high-pressure or dangerous lines.

- Blue: May designate low-pressure or return lines, complementing the color coding on the hoses.

- Orange: Used to mark lines with a reduced system pressure.

Conclusion

Understanding the hydraulic hose color code is essential for safety, efficiency, and proper hydraulic system maintenance. By learning to identify hoses by color, operators can prevent mistakes, ensure correct fluid handling, and reduce the risk of accidents or costly downtime. This knowledge is a vital part of every hydraulic professional’s toolkit.

Proper hose identification also simplifies maintenance and replacement, helping to extend the life of your hydraulic systems. Color-coded hoses make it easier to track different fluid lines, reduce confusion, and maintain consistent system performance. Implementing these standards supports both operational efficiency and workplace safety.

If you’re looking for reliable hydraulic hoses that meet industry standards, Kingdaflex offers a wide range of high-quality products. Get your wholesale hydraulic hoses from Kingdaflex today and ensure durable, safe, and efficient solutions for all your hydraulic applications.