In any fluid transfer system, maximizing efficiency is key to saving energy and ensuring peak performance. One of the most critical, yet often overlooked, factors affecting this is friction loss. This phenomenon, where pressure is lost as fluid moves through a hose, can significantly impact the effectiveness of your pumps and equipment.

Understanding friction loss is essential for designing and operating an efficient system. This guide will demystify what friction loss is, explore the factors that influence it, and provide you with the tools and calculations needed to accurately measure and minimize its effects on your layflat hoses.

What is Layflat Hose Friction Loss?

Layflat hose friction loss is the pressure drop that occurs as fluid flows through a hose due to the resistance from the hose’s inner wall. This resistance, or friction, converts some of the fluid’s energy into heat, resulting in a loss of pressure between the pump and the discharge point.

The amount of friction loss is influenced by several factors, including the hose’s diameter, length, and the flow rate of the fluid. Understanding and calculating this pressure loss is essential for designing an efficient fluid transfer system, as it directly impacts the required pump power and overall operational performance.

How to Calculate Layflat Hose Friction Loss?

Calculating layflat hose friction loss is crucial for system design. By quantifying the pressure drop, you can select the correct pump and hose to ensure optimal efficiency and performance, avoiding wasted energy and poor flow rates.

Step 1: Gather Your Data

The first step is to collect all the necessary information about your system. You need to determine the desired flow rate of the fluid (typically in GPM or LPM), the hose’s inside diameter, and the total length of the hose run.

You also need the hose’s roughness coefficient, which is a value specific to the inner lining material. This information is usually provided by the hose manufacturer in a technical data sheet or a friction loss chart.

Step 2: Choose a Formula

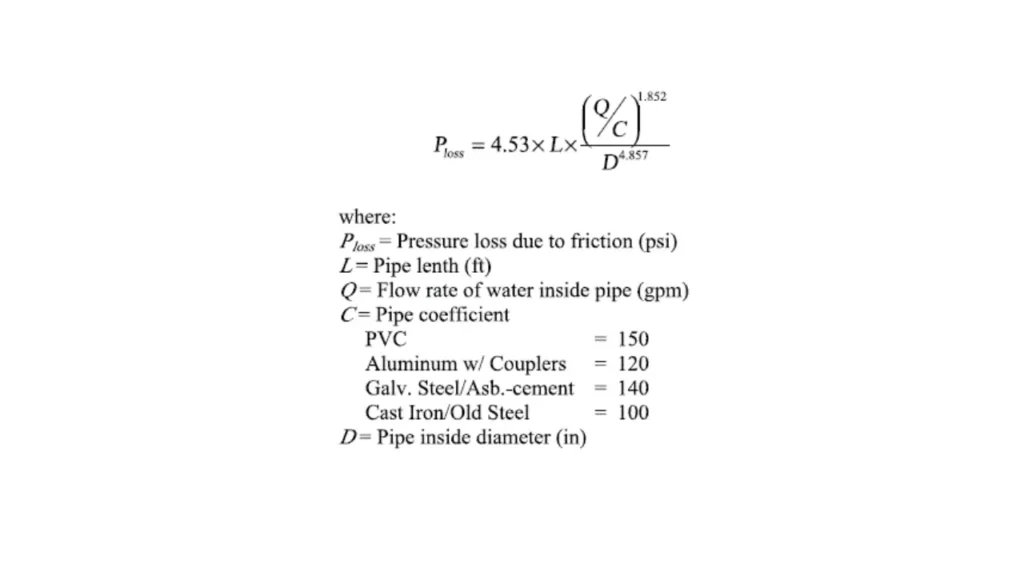

For most water transfer applications, the Hazen-Williams formula is the standard and simplest method for calculating friction loss. This equation uses the flow rate, hose diameter, and roughness coefficient to estimate the pressure drop.

For more complex fluids or greater accuracy, the Darcy-Weisbach equation can be used. This formula is more versatile as it accounts for fluid viscosity and specific gravity, which are important for non-water applications.

Step 3: Perform the Calculation

Plug your gathered data into the chosen formula. You will be able to determine the friction loss per unit of hose length, typically in PSI per 100 feet. This result provides a standardized measure of the pressure drop.

Once you have the friction loss per 100 feet, simply multiply this value by the total length of your hose in 100-foot increments. This final number represents the total pressure loss for the entire hose run.

Step 4: Account for Other Losses

Friction loss is just one part of the total pressure drop. You must also calculate the static head, which is the pressure required to lift the fluid to a higher elevation. This is a critical factor in vertical fluid transfer.

Additionally, account for minor losses caused by fittings, bends, valves, or sudden changes in hose size. By adding all these losses together, you get the total system head, which is the minimum pressure your pump must produce.

Layflat Hose Friction Loss Calculator

Use our calculator to accurately determine the friction loss in your layflat hose system. Understanding this pressure drop is essential for selecting the correct pump and hose, ensuring peak efficiency and performance.

Our layflat hose friction loss calculating tool helps you avoid energy waste and make informed decisions for your fluid transfer projects.

Layflat Hose Friction Loss Calculator

Calculate the pressure drop in your layflat hose system. Enter the required values to determine friction loss and optimize your fluid transfer projects.

Typical ‘C’ values: PVC (140), Rubber (100). Higher values indicate smoother surfaces.

Results

Friction Loss: 0.00 PSI

Note: This is an estimate based on the Hazen-Williams formula for water.

Why Layflat Hose Friction Loss Matters

Understanding layflat hose friction loss is crucial because it directly impacts the performance and efficiency of any fluid transfer system. This pressure drop reduces the effective output of your pump, meaning you get less flow and pressure at the end of the line than the pump is rated for. Ignoring friction loss can lead to poor system performance, wasted energy, and increased wear on your equipment as the pump works harder to compensate for the lost pressure. By accurately calculating and minimizing friction loss, you can ensure your system operates at peak efficiency.

- Reduces Pump Efficiency: Friction loss lowers the pressure and flow rate at the discharge point, making the pump work harder to achieve a desired result.

- Increases Energy Costs: A less efficient system requires more energy to run, leading to higher fuel or electricity bills over time.

- Impacts System Performance: Without considering friction loss, a system may not meet the required flow and pressure for the application, such as agricultural sprinklers or construction dewatering.

- Prolongs Equipment Life: Minimizing friction loss reduces the strain on your pump, potentially extending its lifespan and lowering maintenance costs.

How to Reduce Layflat Hose Friction Loss?

Reducing friction loss in layflat hoses is a key goal for maximizing system efficiency. The most effective way to achieve this is by minimizing the factors that cause friction in the first place. You can do this by increasing the hose's inside diameter, which allows a larger volume of fluid to flow through with less resistance.

Shortening the hose length reduces the total surface area over which friction can occur. Choosing a hose with a smooth inner lining and ensuring the hose is laid out straight, without kinks or sharp bends, also significantly lowers the pressure drop and boosts overall performance.

- Increase Layflat Hose Diameter: A larger diameter hose can handle a higher flow rate at a lower velocity, dramatically reducing friction loss.

- Shorten Layflat Hose Length: The longer the hose, the greater the total friction. Use the shortest practical length for the application.

- Use a Smooth Inner Lining: Hoses with a smooth interior surface have a higher C-factor (coefficient of roughness) and create less turbulence and friction.

- Avoid Kinks and Bends: Lay the hose out as straight as possible. Every sharp bend, twist, or kink creates turbulence and significant pressure loss.

- Maintain Your Layflat Hose: Regularly clean the inside of the hose to prevent the buildup of debris or sediment, which can increase the roughness of the inner surface.

Conclusion

Understanding and accounting for friction loss is a fundamental skill for anyone working with fluid transfer systems. By applying the principles and calculations outlined in this guide, you can make informed decisions about your hose selection and system design, ultimately leading to greater energy savings and more efficient operations.

Minimizing friction loss is more than just an academic exercise; it's a practical step toward improving the reliability and performance of your equipment. A system that accounts for this pressure drop will experience less strain, operate more smoothly, and require less power to achieve the desired flow rate.

For all your fluid transfer needs, Kingdaflex is your reliable source for premium-quality, wholesale layflat hoses. Our hoses are engineered for maximum flow and minimal friction loss, ensuring superior performance for your projects. Choose Kingdaflex for high-efficiency and cost-effective solutions you can trust.