We supply Oxygen Acetylene hoses that are designed for safe and efficient welding applications. Our hoses are engineered to withstand the high pressures and temperatures associated with oxygen and acetylene gases, ensuring reliable performance and minimal risk of leaks or ruptures.

Our oxygen and acetylene hoses are engineered with safety in mind. The color-coded system (green for oxygen, red for acetylene) helps prevent accidental gas mixing, reducing the risk of dangerous explosions.

Our oxygen and acetylene hose is designed to deliver consistent and reliable performance. They are resistant to kinking and twisting, ensuring a smooth flow of gases to your welding torch.

Made from high-quality materials, our oxygen and acetylene hoses are built to last. They can withstand the high pressures and temperatures associated with oxygen and acetylene gases without compromising their integrity.

We adhere to industry standards and regulations, ensuring that our oxygen and acetylene hoses meet the highest quality and safety requirements.

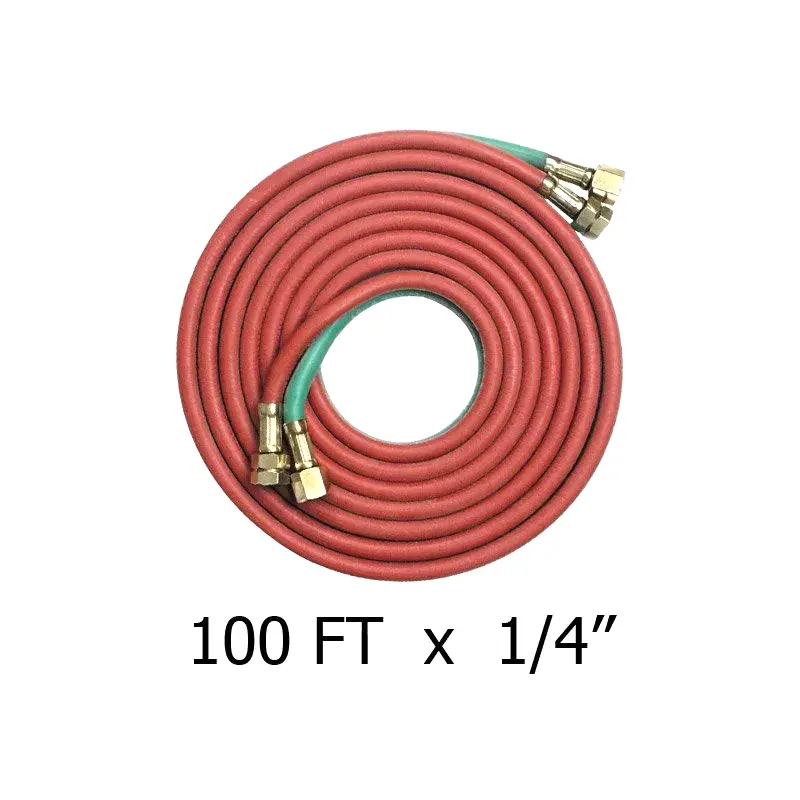

We offer a 100-foot oxygen acetylene hose that is ideal for a variety of welding applications. This high-quality hose provides the length and durability needed for both residential and professional use.

A 1/4″ oxygen-acetylene twin hose is a popular choice for many welding applications due to its balance of flow capacity and portability. It’s ideal for medium-duty tasks like cutting, brazing, and light-duty welding.

We offer high-quality 3/16-inch oxygen acetylene hoses that are perfect for a wide range of welding applications. This popular hose size provides a balance of flow capacity and portability, making it a versatile choice for both professional and DIY welders.

Twin hose oxygen acetylene systems offer a convenient and efficient way to supply both oxygen and acetylene gases to your welding torch. These systems feature two hoses bundled together, often with a single regulator, making it easier to manage and transport your welding equipment.

An oxy-acetylene hose is a specialized type of hose used to deliver oxygen and acetylene gases to a welding torch. These gases are mixed together to create a high-temperature flame that is used for cutting, welding, and heating metals.

Key features of oxy-acetylene hoses:

Oxy-acetylene hoses are used in a variety of industries, including:

Would you like to know more about the different types of oxy-acetylene hoses or their specific applications?

Oxygen and acetylene hose color

Oxygen hoses are typically green, while acetylene hoses are typically red.

This color coding is a universal standard used to prevent accidental mixing of gases, which can be extremely dangerous in welding applications.

Acetylene and oxygen hoses typically have different fittings to prevent accidental mixing of gases. This is a crucial safety measure in welding.

Here are some common differences between acetylene and oxygen hose fittings:

It’s important to always check the fittings and connectors carefully before connecting them to ensure proper and safe operation. If you’re unsure about the fittings, consult the user manual for your welding equipment or seek guidance from a qualified professional.

Oxygen hoses are specifically designed to handle the high pressure and purity requirements of oxygen gas. They are typically made from materials that are resistant to oxidation and other chemical reactions that can occur with oxygen.

Common materials used for oxygen hoses include:

When selecting an oxygen hose, it’s important to consider the following factors:

By choosing an appropriate oxygen hose, you can ensure safe and efficient delivery of oxygen gas to your welding or cutting equipment.

We are leading hydraulic hose manufacturer from China, and please feel free to contact us at any time if you are looking for hydraulic hoses, hydraulic hose fittings, industrial hoses, and other hose related products. Welcome to get in touch with us any time to get more hose solutions for your projects.

If you are looking for a professional hydraulic hose & industrial hose manufacturer, Kingdaflex will be your best choice. We provide better hydraulic hose wholesale and the best solution to help your hydraulic projects. Welcome to contact us at any time.