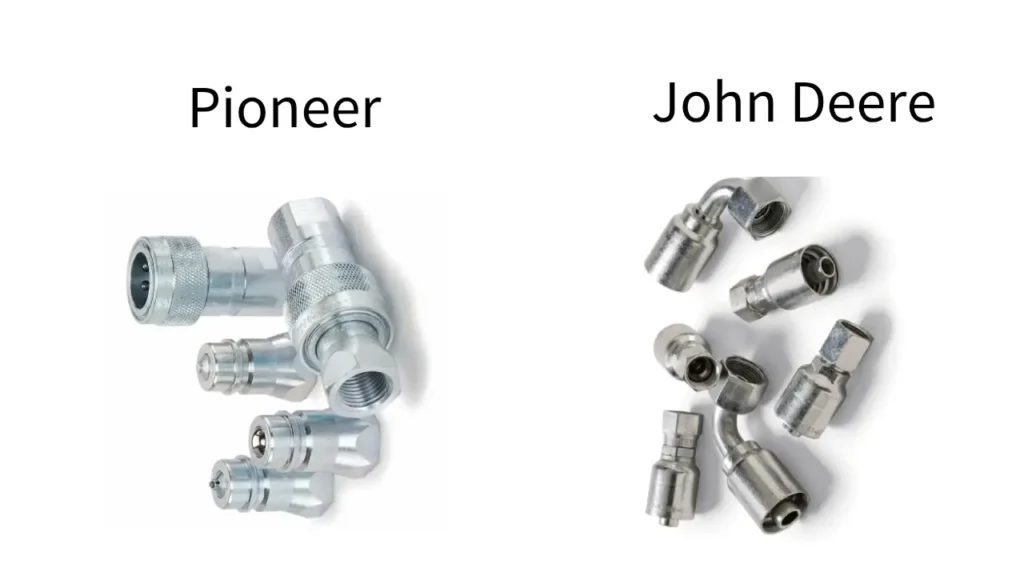

When dealing with agricultural equipment, differentiating between Pioneer and John Deere hydraulic fittings is a common challenge. While both are widely used, particularly in quick-connect applications for tractors and implements, they often feature distinct designs and specifications. Understanding these differences is crucial for ensuring proper connections and preventing costly fluid leaks or system damage.

This guide will help you identify the unique characteristics of Pioneer and John Deere hydraulic fittings. We’ll delve into their typical appearances, thread types, and sealing mechanisms, empowering you to select the correct hydraulic fitting for your equipment and avoid compatibility issues in the field.

What are Pioneer Hydraulic Fittings?

Pioneer hydraulic fittings, particularly “Pioneer” quick couplers, refer to a specific and widely recognized standard of quick-disconnect hydraulic couplings primarily used in agricultural equipment. Developed by the Pioneer company (which later became part of Parker Hannifin), these fittings are known for their robust design and ability to connect and disconnect hydraulic lines quickly and efficiently, even in demanding farm environments.

They typically feature a poppet or ball valve design and often include a collar that needs to be pulled back for connection. The 8010 Series universal tips are often considered an industry standard within agricultural applications, making “Pioneer” a common reference for this type of quick coupler.

What are John Deere Hydraulic Fittings?

John Deere hydraulic fittings refer to the specific types of hydraulic quick couplers and other connection components designed for or commonly found on John Deere agricultural, construction, and forestry equipment. While John Deere manufactures some proprietary fittings, they also extensively use and specify industry-standard fittings, particularly those adhering to ISO 5675 (Agricultural Interchangeability) for quick couplers.

These John Deere fittings are engineered to withstand the rigorous demands of heavy machinery, ensuring reliable and leak-free performance under high pressure, often featuring robust construction suitable for challenging outdoor environments. The use of specific John Deere part numbers for fittings also signifies compliance with their internal design and quality standards, ensuring perfect compatibility and optimal performance with their machinery.

Pioneer vs John Deere Hydraulic Fittings

When working with agricultural machinery, understanding the differences between Pioneer and John Deere hydraulic fittings is critical for ensuring proper compatibility and preventing system issues. While both serve to connect hydraulic lines, their specific designs and adherence to standards can vary. This comparison will help clarify their distinctions across key aspects.

1. Standardization and Interchangeability

Pioneer hydraulic fittings are largely synonymous with the ISO 5675 standard for agricultural quick-release couplings. This means that a “Pioneer style” coupler from one manufacturer is generally interchangeable with another that adheres to ISO 5675, promoting broad compatibility across different brands of farm implements.

John Deere hydraulic fittings, historically, had their own proprietary designs, particularly on older models. While newer John Deere equipment largely adopted the ISO 5675 standard for common auxiliary circuits, older “John Deere old-style” couplers were not universally interchangeable with Pioneer or other ISO 5675 fittings without adapters.

2. Valve Design

Pioneer-style (ISO 5675) quick couplers typically utilize a poppet valve or ball valve design within both the male tip and female body. These valves seal the fluid path when disconnected and open when connected, though they can sometimes be prone to minor fluid spillage upon disconnection.

John Deere, especially on older equipment, used unique valve designs. While many newer John Deere systems use ISO 5675 (Pioneer-style) couplers with poppet/ball valves, some applications, or newer John Deere developments, might incorporate flat-face couplers (ISO 16028) which offer minimal spillage.

3. Connection Mechanism

Pioneer-style (ISO 5675) couplings generally feature a push-pull sleeve mechanism on the female coupler. To connect, the male tip is pushed into the female coupler, and a locking collar or sleeve automatically engages. Disconnection is achieved by pulling back the sleeve.

John Deere fittings, particularly the older proprietary versions, might have slightly different locking or release mechanisms, though current ISO 5675 compliant fittings on John Deere machines operate similarly to the Pioneer style.

4. Pressure Ratings

Both Pioneer-style (ISO 5675) and John Deere hydraulic fittings are designed to handle the high pressures typical in agricultural hydraulic systems. Pioneer 4000 series (ISO 5675) couplers, for instance, are commonly rated for around 3000 PSI. While specific John Deere fittings will also have high-pressure ratings suitable for their heavy-duty equipment, the general pressure capacity of ISO 5675 fittings is sufficient for most standard agricultural implements.

However, for extremely high-pressure applications, John Deere, like other manufacturers, might specify different fitting types, possibly including flat-face couplers which can have higher pressure ratings than traditional poppet-style ISO 5675.

5. Application Focus

Pioneer hydraulic fittings, by their very name and the ISO 5675 standard they embody, are predominantly found in agricultural machinery. They are designed for the frequent connection and disconnection of implements to tractors. John Deere hydraulic fittings are, by default, specific to John Deere’s vast range of agricultural, construction, and forestry equipment.

While John Deere utilizes ISO 5675 for interchangeability with many implements, their specific applications can also involve proprietary fittings or a broader range of industrial fitting types (like JIC, ORFS, or SAE flanges) depending on the equipment series and its operational demands beyond simple quick-connect hydraulics.

6. Historical Development and Evolution

Pioneer, as a brand, played a significant role in establishing a widely accepted quick-coupler standard (ISO 5675) for agricultural equipment. This allowed for greater interchangeability between tractors and implements from various manufacturers. John Deere, being a major equipment manufacturer, historically had its own proprietary quick-coupler designs on older tractors, which often required adapters to connect to “Pioneer style” implements.

Over time, John Deere progressively adopted the ISO 5675 standard for many of its quick-coupler applications, especially on auxiliary hydraulic circuits, leading to greater compatibility with the broader agricultural market while still maintaining their own specific part numbers and quality control for other system components.

Here is a table showing you the differences between pioneer hydraulic fittings and John Deere:

| Feature / Aspect | Pioneer Hydraulic Fittings (ISO 5675 Standard) | John Deere Hydraulic Fittings (General) |

|---|---|---|

| Primary Standardization | ISO 5675 (Agricultural Quick-Release Couplings) | Primarily ISO 5675 for many auxiliary circuits on newer equipment; some older proprietary designs, and also utilizes other industrial standards (e.g., JIC, ORFS, SAE flanges) depending on the specific machine and application. |

| Valve Design | Typically Poppet or Ball Valve | Predominantly Poppet or Ball Valve (for ISO 5675 compliant); some applications may use Flat-Face (ISO 16028) or older proprietary designs. |

| Connection Mechanism | Push-pull sleeve on female coupler for connection/disconnection | Similar push-pull sleeve mechanism for ISO 5675 compliant fittings; older proprietary designs may have unique locking or release mechanisms. |

| Typical Pressure Rating | ~3000 PSI (for common agricultural applications) | Designed for high pressures, ratings vary by specific fitting type and application, often matching or exceeding ISO 5675 ratings for quick couplers; specific John Deere heavy-duty applications may utilize fittings with higher pressure ratings. |

| Main Application Focus | Broad agricultural machinery interchangeability, implements to tractors | Designed specifically for John Deere agricultural, construction, and forestry equipment; ensures compatibility within John Deere’s ecosystem, while also embracing ISO 5675 for broader agricultural implement compatibility. |

| Interchangeability | High interchangeability with other ISO 5675 compliant fittings | High interchangeability with ISO 5675 fittings on newer equipment; older proprietary John Deere fittings often require adapters for compatibility with ISO 5675 (“Pioneer style”) fittings. |

How to Choose Pioneer and John Deere Hydraulic Fittings

Choosing the correct hydraulic fittings for your equipment, whether it’s a “Pioneer” style quick coupler or a specific John Deere fitting, is paramount for operational safety and efficiency. The primary consideration is always compatibility with your existing machinery and implements. Mismatched fittings can lead to leaks, pressure loss, or even system damage, resulting in costly downtime and potential hazards. Therefore, carefully identifying the exact fitting type, size, and sealing method is essential.

Beyond direct compatibility, consider the operating environment and the specific demands of your application. Factors such as typical operating pressure, temperature extremes, and the presence of corrosive fluids will influence the material and design of the fittings you select. Always prioritize fittings that meet relevant industry standards (like ISO 5675 for agricultural quick couplers) to ensure quality, reliability, and broad interchangeability where applicable.

Choosing the correct hydraulic fittings for your equipment, whether it’s a “Pioneer” style quick coupler or a specific John Deere fitting, is paramount for operational safety and efficiency. The primary consideration is always compatibility with your existing machinery and implements. Mismatched fittings can lead to leaks, pressure loss, or even system damage, resulting in costly downtime and potential hazards. Therefore, carefully identifying the exact fitting type, size, and sealing method is essential.

Beyond direct compatibility, consider the operating environment and the specific demands of your application. Factors such as typical operating pressure, temperature extremes, and the presence of corrosive fluids will influence the material and design of the fittings you select. Always prioritize fittings that meet relevant industry standards (like ISO 5675 for agricultural quick couplers) to ensure quality, reliability, and broad interchangeability where applicable.

- Identify the Equipment: Determine if your tractor or implement is designed for “Pioneer-style” (ISO 5675) quick couplers or if it uses older, proprietary John Deere fittings. For newer John Deere equipment, most auxiliary hydraulics will likely be ISO 5675 compatible.

- Check Existing Fittings: Examine the existing hydraulic fittings on your machinery. Look for any identifying marks, part numbers, or branding. If possible, measure the thread size, pitch, and verify the sealing cone or face angle.

- Consider Application: For implements that will be frequently connected and disconnected across different tractor brands, Pioneer-style (ISO 5675) quick couplers are generally the best choice for broad interchangeability.

- Prioritize Safety and Performance: Never compromise on fitting quality. Choose fittings that can safely handle the maximum operating pressure and temperature of your hydraulic system.

- Seek Expert Advice: If uncertain, consult with a reputable hydraulic fitting manufacturer & supplier or a John Deere dealership. Consult Kingdaflex for their wide range of hydraulic fittings and expert guidance on compatibility and selection. They can provide specific guidance based on your equipment’s model and serial number, ensuring you select the correct and safest hydraulic fittings.

Conclusion

This blog effectively differentiates between Pioneer and John Deere hydraulic fittings, highlighting their unique designs and applications, particularly within the agricultural sector. Understanding these distinctions is crucial for proper equipment compatibility and operational efficiency.

The comparison emphasizes that while both types serve the same fundamental purpose of fluid conveyance, their specific characteristics, such as sealing mechanisms or connection methods, necessitate careful selection to prevent system malfunctions or leaks. This detailed insight empowers users to choose the correct fittings for their machinery.

For those in search of reliable wholesale hydraulic fittings, our Kingdaflex offers a wide array of options compatible with various systems, ensuring you can find the right fit for your needs.