Plastic spiral hose guards are designed to protect hydraulic and industrial hoses from abrasion, crushing, and external wear in demanding operating conditions.

Commonly used in construction equipment, mining machinery, and mobile hydraulics, our spiral guards are manufactured for bulk supply and OEM applications, helping extend hose service life and reduce maintenance in harsh environments.

Flat surface plastic spiral hose guards feature a wider contact area between the guard and external surfaces, providing strong abrasion and impact resistance.

This design is suitable for heavy-duty applications where hoses are frequently exposed to rough contact, friction, and mechanical wear. Flat surface spiral guards are commonly used in construction equipment, mining machinery, and other demanding environments requiring durable hose protection.

Convex or arc-surface plastic spiral hose guards are designed to reduce friction while maintaining hose flexibility. The curved surface helps hoses slide more easily against surrounding components, making this type suitable for applications with frequent movement and bending.

Convex spiral guards are often used in mobile hydraulic systems, agricultural machinery, and equipment where hose mobility and protection must be balanced.

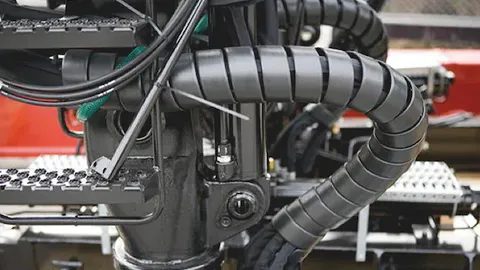

Plastic spiral hose guards are widely used on excavators, loaders, and construction machinery to protect hydraulic hoses from abrasion, crushing, and external wear caused by continuous movement and contact with rough surfaces.

Agricultural and forestry equipment use plastic spiral guards to protect hoses from abrasion, impact, and environmental exposure during field operations, helping maintain reliable hose performance and reduce maintenance requirements.

Mobile hydraulic systems rely on spiral hose guards to prevent hose wear caused by friction, bending, and movement. The spiral design maintains flexibility while providing consistent protection in dynamic operating conditions.

In industrial hose assemblies, plastic spiral guards are used to separate hoses, reduce surface wear, and improve routing organization, supporting longer hose life and safer system operation.

Made from high-strength plastic materials for abrasion and impact resistance

Protects hoses from surface wear, friction, and external mechanical damage

Suitable for outdoor use with basic UV and weather resistance

Spiral structure allows easy installation without removing hose fittings

Reusable during maintenance or hose replacement

Material grade and temperature suitability selected based on actual operating conditions

In-house manufacturing capability ensures stable production capacity, controlled processes, and consistent spiral guard quality for long-term OEM and bulk supply requirements.

Designed specifically for hydraulic hose protection, our spiral guards are engineered to fit common hose sizes without restricting flexibility or installation.

OEM and bulk supply experience supports distributors, equipment manufacturers, and industrial customers with reliable specifications, packaging options, and repeat-order consistency.

Consistent dimensions and material quality help ensure proper fitment, predictable performance, and smooth integration into hydraulic hose assemblies and protection systems.

Temperature Range: 260°C – 1650°C; Continuous operating temperature: 500°F (260°C); Max short term exposure: 3000°F (1650°C).

Choosing the right hose protection depends on the operating environment and hose application. Key factors include abrasion level, temperature exposure, risk of flame or molten splash, hose outer diameter, and flexibility requirements.

Fire sleeves are suitable for high-temperature environments, while sheathing and spiral guards are ideal for abrasion-prone applications. Selecting protection that matches real working conditions ensures effective performance and long-term reliability.

Choosing the right fire sleeve depends on installation method, maintenance frequency, and application environment. Tube-style fire sleeves are ideal for OEM hose assemblies and permanent installations. Snap button, zipper, and hook & loop fire sleeves are suitable for retrofitting existing hoses or applications requiring frequent inspection, maintenance, or replacement in industrial facilities.

Yes, fire sleeves are widely used in OEM hydraulic hose assemblies. Tube-style fire sleeves are especially suitable for OEM production lines due to their fully enclosed structure and consistent dimensions. They can be integrated during hose assembly and crimping processes, providing long-term thermal protection for hydraulic systems used in heavy equipment and industrial machinery.

Fire sleeves can be fully customized for bulk and OEM orders. Customization options include inner diameter, length, wall thickness, performance level, color, and packaging. OEM branding and private labeling are also available. Working directly with an experienced manufacturer like Kingdaflex ensures stable quality, proper fitment, and reliable supply for large-volume industrial projects.