Engineered for extreme conditions, Kingdaflex SAE 100R14 PTFE hoses excel where standard rubber fails. Featuring SUS304 stainless steel braiding, they withstand temperatures from -50°C to +210°C (instant +260°C) and resist aggressive media like petroleum, chemicals, and steam. This ensures the longest possible service life. Choose between Inner Smooth Tube for high flow or Inner Corrugated Tube for superior flexibility.

Kingdaflex SAE 100R14 hose is manufactured in strict accordance with SAE J517 standards.

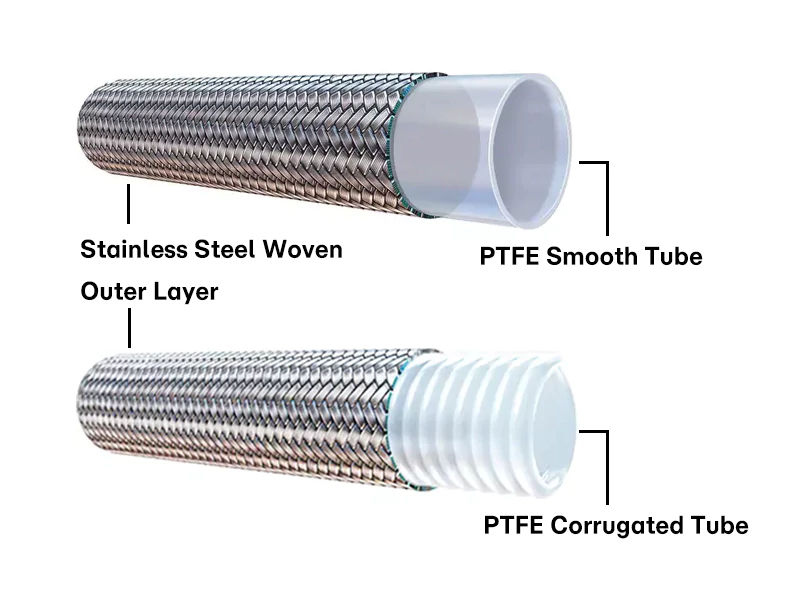

Our hoses feature a premium PTFE (Polytetrafluoroethylene) core reinforced with a single layer of SUS304 stainless steel wire braid (SUS316 available on request).

This construction ensures the hose remains lightweight while delivering exceptional pressure containment and temperature resistance from -50°C to +210°C.

Commonly used as r14 fuel hose for gasoline, diesel, and alternative fuels. Also ideal for turbocharger oil feed lines, brake systems, and transmission fluid transfer due to its high heat resistance.

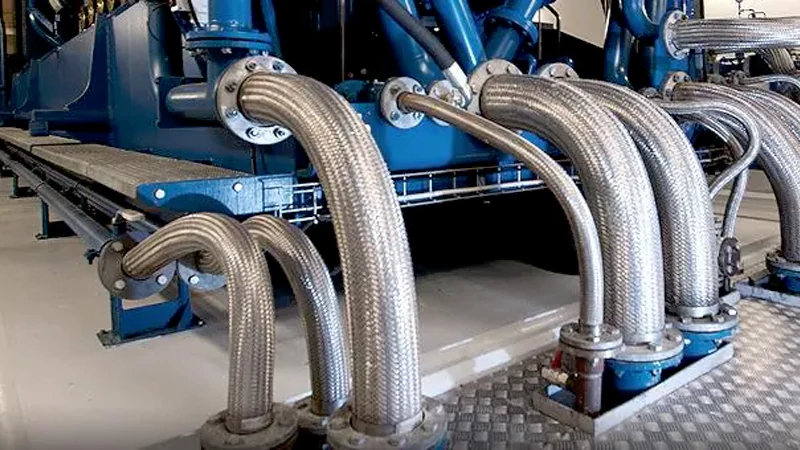

Hydraulic lines for injection molding machines, rubber and plastic manufacturing equipment, and heavy-duty 100r14 hydraulic hose applications where rubber hoses degrade too quickly.

Safe transfer of acids, alkalis, solvents, and corrosive gases. The non-stick surface ensures easy cleaning and no media contamination.

High-temperature steam lines (up to 260°C instant use) and air compressor discharge lines.

Choose Smooth Bore when you need to maintain high flow rates (low pressure drop) or require easy cleaning/sterilization (e.g., food or paint industries).

Choose Corrugated Bore when the installation space is tight and the hose must undergo frequent bending or vibration (e.g., engine compartments or dynamic machinery). The convoluted design offers a significantly smaller bend radius compared to smooth bore.

From raw material testing to final impulse testing, ensuring zero defects.

State-of-the-art braiding and spiraling machines for consistent precision.

Trusted by customers in over 50 countries across Europe, Middle East, and Americas.

Private labeling (OEM), custom lengths, and assembly services available.

We provide more than just bulk hose; we offer complete 100r14 hose assembly solutions to save your production time and ensure safety.

Since SAE 100R14 hoses are often used in corrosive or high-temperature environments, selecting the right 100r14 hose fittings is as important as the hose itself. Kingdaflex offers a “Complete Solution” crimping service:

We stock a wide range of couplings including JIC, BSP, NPT, ORFS, and Metric standards to match your equipment interfaces.

Available in Stainless Steel (SUS304/316) for superior corrosion resistance, or Carbon Steel for cost-effective standard hydraulic and fuel applications.

All assemblies are professionally crimped and tested to ensure they handle the rated working pressure (up to 3625 PSI for smaller sizes) without leaking.

For SAE 100R14 hoses operating in high-heat zones (such as steel mills, glassworks, or near engine manifolds), external protection is essential to prevent premature failure.

We strongly recommend pairing your PTFE hose with our Fire Sleeve to maximize service life.

Made of braided fiberglass coated with high-quality silicone rubber, our Fire Sleeve operates from 260°C to 1300°C.

It is specifically designed to protect hoses from occasional flame, molten metal splashes, and high heat hazards.

The silicone coating is resistant to hydraulic fluids, lubricating oils, and fuels, adding an extra layer of defense.

Choosing the right SAE 100R14 hose structure is critical for system efficiency and longevity. As a manufacturer with over 15 years of experience, we recommend basing your decision on flow requirements versus installation space.

Choose SAE 100R14 Smooth Bore (Inner Smooth Tube) if:

Choose SAE 100R14 Convoluted (Inner Corrugated Tube) if:

Kingdaflex SAE 100R14 hoses are designed for extreme thermal environments. They withstand a constant use temperature range of -50°C to +210°C and can handle instant exposure up to +260°C. This makes them superior to standard rubber hoses for high-heat applications.

Yes. Due to the chemical inertness of the PTFE tube, this hose is an excellent r14 fuel hose. It is widely used for diesel alternate liquid and gas applications. It resists the corrosive effects of modern fuels and additives that often degrade rubber liners.

Yes. We can supply the hose with SUS304 stainless steel braiding where all kinds of couplings can be available. We provide complete 100r14 hose assembly services, crimping the hose with your specified fittings (JIC, NPT, BSP, etc.) for immediate installation.

Standard PTFE is non-conductive (Type B). However, for applications requiring static dissipation (such as fuel transfer), we can manufacture hoses with a conductive carbon-lined core (Type A). Please specify your requirement for sae j517 100r14 type a when requesting a quote to ensure safety against static buildup.

For areas with extreme radiant heat or molten splash, we recommend covering the R14 hose with our Fire Sleeve. It is made of braided fiberglass coated with silicone rubber and resists temperatures from 260°C to 1300°C