We provide SS corrugated hoses, known for their flexibility and durability. They are made from high-quality stainless steel, making them resistant to corrosion, high temperatures, and harsh chemicals. These hoses are widely used in various industries, including food processing, pharmaceuticals, and chemical plants.

We are one of the leading stainless steel corrugated hose manufacturers that you can trust, dedicated to providing our customers with top-rated ss corrugated hose pipe that meet the highest industry standards.

Our stainless steel corrugated hose is crafted from high-quality stainless steel, ensuring exceptional resistance to corrosion, extreme temperatures, and harsh chemicals. This translates to extended service life and reduced maintenance costs.

Our corrugated hose stainless steel are engineered to deliver optimal performance across a wide range of demanding applications. They offer high flow rates, low pressure drop, and excellent vacuum resistance.

The corrugated design provides unmatched flexibility, allowing for easy installation and maneuverability in confined spaces. This adaptability simplifies system integration and reduces installation time.

Our SS corrugated hose pipes are suitable for a diverse array of industries, including food processing, pharmaceuticals, chemical processing, and more. We offer a variety of sizes and configurations to meet your specific needs.

We provide corrugated stainless steel flexible hose, renowned for their exceptional durability and flexibility. Crafted from high-quality stainless steel, they offer superior resistance to corrosion, high temperatures, and harsh chemicals. Ideal for demanding applications in various industries, including food processing, pharmaceuticals, and chemical plants.

We provide corrugated metal hoses, known for their flexibility and durability. They are constructed from various metals, including stainless steel, offering excellent resistance to corrosion, high temperatures, and harsh chemicals. These hoses are widely used in industries like food processing, pharmaceuticals, and chemical plants, where demanding conditions require reliable and adaptable solutions.

We provide high-quality stainless steel flexible metal corrugated drinking water hoses. Crafted from food-grade stainless steel, they are durable, corrosion-resistant, and ensure hygienic water delivery. Their flexibility allows for easy installation and maneuverability in confined spaces. These hoses are ideal for residential, commercial, and industrial applications where safe and reliable drinking water supply is crucial.

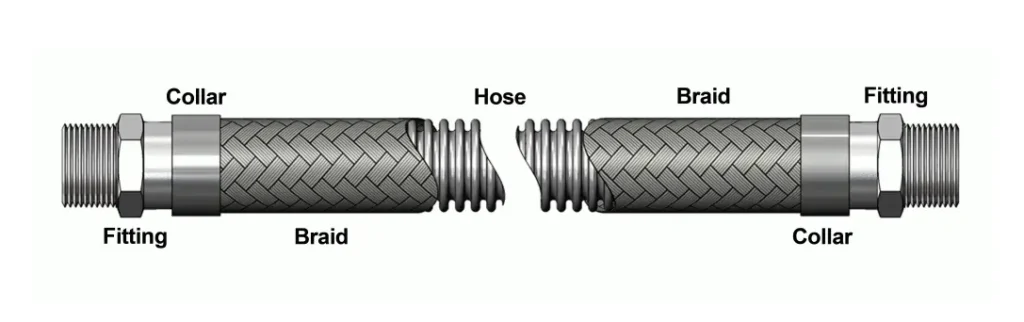

We provide Corrugated Metal Hose Assemblies, which are complete hose systems incorporating the hose with fittings at each end. These assemblies offer a convenient and ready-to-install solution for various applications. We use high-quality materials and precision manufacturing techniques to ensure leak-free connections and optimal performance.

An SS corrugated hose is a type of flexible pipe made from stainless steel. It’s designed with ridges or folds along its length, giving it a wavy appearance.

SS corrugated hoses find extensive use across various industries due to their unique properties:

Food Processing:

Pharmaceutical Industry:

Chemical Processing:

Marine Applications:

HVAC Systems:

Industrial Machinery:

These are just a few examples of the many applications where SS corrugated hoses prove invaluable. Their versatility, durability, and resistance to harsh environments make them a preferred choice in numerous industrial settings.

The pressure rating of SS corrugated hoses can vary significantly depending on several factors, including:

Typical Pressure Ratings:

It’s crucial to consult the manufacturer‘s specifications for the specific SS corrugated hose you are considering. However, to give you a general idea, typical pressure ratings can range from a few hundred psi to several thousand psi.

Important Note: Always use SS corrugated hoses within their rated pressure limits to ensure safe and reliable operation. Exceeding the pressure rating can lead to hose failure, potential injuries, and property damage.

If you have a specific application in mind, it’s best to consult with a hose supplier or engineer to select the appropriate SS corrugated hose with the correct pressure rating for your needs.

1. Preparation

2. Measurement and Cutting

3. Attach Fittings

4. Support and Installation

5. Inspection and Testing

Important Notes:

By following these steps and taking necessary precautions, you can ensure a safe and successful installation of your SS corrugated hose.

The lifespan of an SS corrugated hose can vary significantly depending on several factors:

General Lifespan:

While it’s difficult to give an exact number, with proper care and under normal operating conditions, high-quality SS corrugated hoses can last for many years. Some sources suggest a lifespan of 5-10 years or even longer in ideal situations.

Factors that Shorten Lifespan:

Regular Inspection:

Regular visual inspections are crucial to identify potential issues early on. Look for signs of wear and tear, such as:

By carefully considering these factors and implementing proper maintenance practices, you can maximize the lifespan of your SS corrugated hose and ensure reliable performance for years to come.

We are leading hydraulic hose manufacturer from China, and please feel free to contact us at any time if you are looking for hydraulic hoses, hydraulic hose fittings, industrial hoses, and other hose related products. Welcome to get in touch with us any time to get more hose solutions for your projects.

If you are looking for a professional hydraulic hose & industrial hose manufacturer, Kingdaflex will be your best choice. We provide better hydraulic hose wholesale and the best solution to help your hydraulic projects. Welcome to contact us at any time.