As a leading stainless steel braided hose manufacturer in China, we specialize in producing durable hoses for a wide range of industrial, automotive, and commercial applications. Our advanced manufacturing facilities and strict quality control processes ensure that every hose meets the highest standards for performance and longevity. We offer a comprehensive selection of products, tailored to specific client needs, with a focus on providing reliable solutions for demanding environments. Our commitment to competitive pricing and efficient global logistics makes us an ideal partner for businesses worldwide seeking superior braided hose products.

Customization: We provide tailored solutions, including specific lengths, diameters, and end fittings to meet unique project requirements.

Material Quality: Our hoses are typically constructed with high-grade stainless steel (like SS304 or SS316), ensuring excellent corrosion resistance and strength.

Certifications: Our products often comply with international standards and certifications, guaranteeing safety and quality.

Versatile Applications: Our hoses are suitable for various media, including water, gas, oil, and chemicals, and can withstand a wide range of temperatures and pressures.

Kingdaflex is your ideal steel braided hose manufacturer due to our over 20 years of industry experience and commitment to quality. We offer a comprehensive selection of products, including a wide range of braided hydraulic hoses that meet international standards. With advanced manufacturing technology, strict quality control, and a focus on customization, we provide reliable, high-performance solutions at competitive prices.

We offer a wide selection of stainless steel braided hoses, including rubber and PTFE-lined options. Our products are suitable for various applications, such as hydraulic systems, fuel lines, brake systems, and industrial fluid transfer, and are designed to withstand high pressures, extreme temperatures, and corrosive environments. We also provide customized solutions.

We offer high-performance stainless steel braided fuel hoses, engineered for the demanding conditions of automotive and racing applications. Our hoses feature a durable PTFE inner core for superior chemical resistance to gasoline, E85, and other fuels, preventing permeation and degradation. The outer stainless steel braid provides exceptional abrasion resistance and pressure handling, ensuring a safe and reliable fuel delivery system.

We provide premium stainless steel braided brake hoses engineered for superior performance and safety. Our hoses feature a PTFE inner core and a durable SS304 braided outer layer, which eliminates hose expansion for a firmer, more responsive brake pedal feel. They are designed to withstand high pressures and are a direct replacement for stock rubber lines.

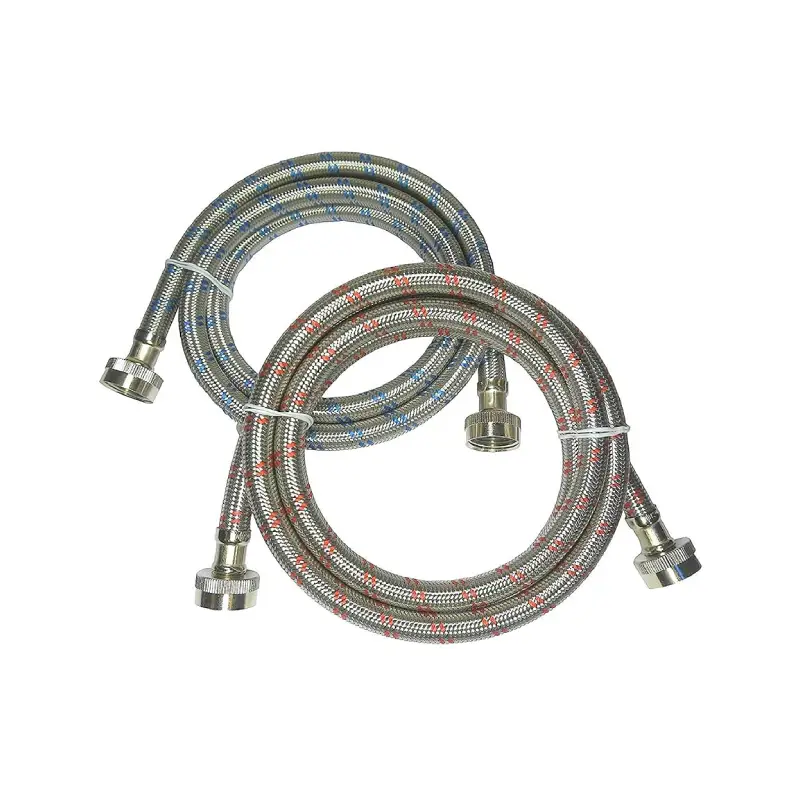

We offer premium stainless steel braided washer hoses designed for durability and leak-free performance. Our hoses feature a reinforced PVC or EPDM core and a braided stainless steel exterior, providing superior pressure resistance and protection against kinking, bursts, and corrosion. They are ideal for connecting washing machines and other appliances, ensuring long-lasting reliability.

We offer premium steel braided radiator hoses designed to replace standard rubber hoses for superior performance and aesthetics. Our hoses feature a reinforced inner layer and a durable stainless steel braid, providing excellent resistance to high temperatures, pressure, and abrasion. Ideal for both show cars and demanding automotive applications, they ensure a long-lasting and reliable cooling system.

We offer a wide range of stainless steel flexible braided hoses for various industrial, automotive, and commercial applications. Our hoses are designed for durability, featuring a robust stainless steel outer braid that provides excellent pressure resistance and protection against abrasion. Available in different core materials, including rubber and PTFE, our hoses ensure reliable and long-lasting performance.

We offer durable and kink-resistant stainless steel braided garden hoses. Made with a flexible inner core and a protective stainless steel outer shell, our hoses are lightweight, tangle-free, and built to withstand punctures, rust, and extreme weather. They are perfect for all your gardening and outdoor watering needs, ensuring a long-lasting, reliable water flow.

We manufacture durable stainless steel braided air compressor hoses, built to withstand high pressures and temperatures. Our air compressor hoses feature a flexible core and a robust stainless steel braid for superior abrasion resistance and a longer lifespan. Ideal for industrial and workshop applications, these hoses ensure reliable, leak-free performance and minimize the risk of a system failure.

We offer specialized stainless steel braided chemical hoses designed for safe and reliable transfer of various corrosive media. Featuring a durable PTFE or PFA liner and a robust stainless steel braid, these hoses provide excellent chemical resistance and high pressure ratings. Ideal for chemical plants, laboratories, and industrial applications, they ensure long-lasting performance and maximum safety.

We offer premium stainless steel braided LPG hoses, engineered for maximum safety and performance. Our hoses feature a high-tensile steel braid over a durable rubber core, providing excellent resistance to pressure, temperature, and corrosion. They are ideal for connecting LPG cylinders to appliances, ensuring a secure and long-lasting gas transfer solution.

We offer a range of stainless steel braided propane hoses, engineered for safety and durability. These hoses are designed to withstand high pressure and resist kinking, abrasion, and rodent damage. Our hoses come in various lengths with different fittings to suit applications from grills and fire pits to RVs and industrial systems, ensuring a secure, leak-proof connection.

We offer high-performance stainless steel braided steam hoses designed for safe and reliable steam transfer in industrial applications. These hoses feature a high-temperature EPDM or butyl rubber inner tube, reinforced with a steel wire braid and an outer stainless steel braid for superior pressure resistance, durability, and protection against abrasion and kinking.

We offer high-performance steel braided Teflon (PTFE) hoses, combining the chemical inertness and wide temperature range of a smooth-bore PTFE inner tube with the strength and pressure resistance of a stainless steel outer braid. Ideal for transferring corrosive chemicals, high-temperature fluids, and gases in automotive, industrial, and food-grade applications, our hoses ensure safety and reliability.

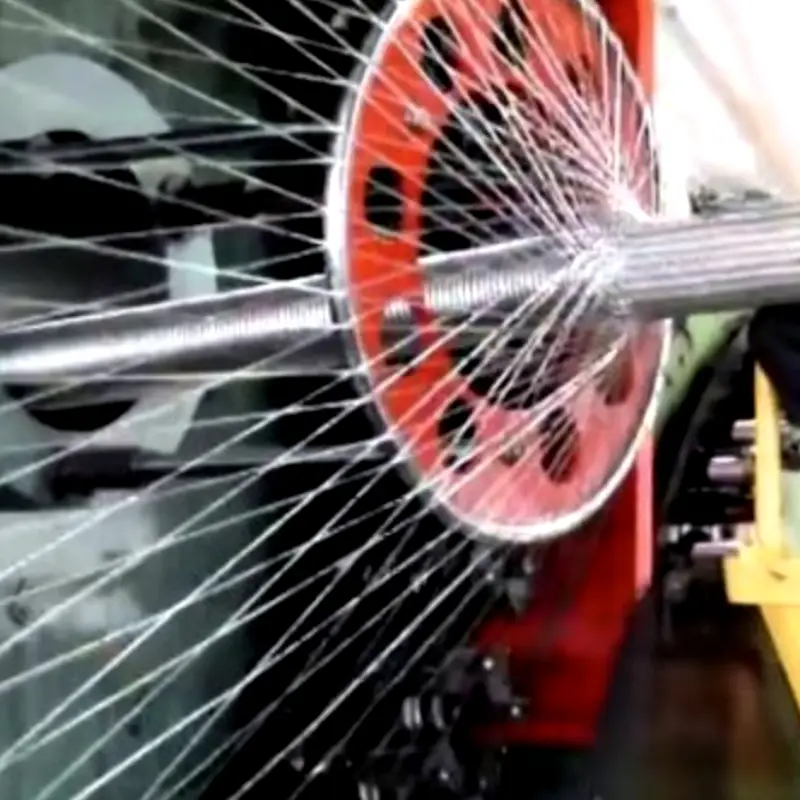

The manufacturing process for stainless steel braided hoses is a multi-step process that combines the production of a flexible inner tube with the application of a high-tensile wire braid. The process is designed to create a hose that is durable, pressure-resistant, and suitable for demanding applications.

Inner Tube Extrusion: The process begins with the extrusion of the inner hose. The base material, such as rubber, PTFE, or thermoplastic, is melted and pushed through a die to create a seamless tube with a uniform wall thickness. This is the core that will carry the fluid or gas.

Braiding: After the inner tube is formed and cooled, a precision braiding machine weaves high-tensile stainless steel wires around it. This reinforcement layer is crucial for providing the hose with its strength, pressure resistance, and protection from external damage and abrasion.

Finishing and Assembly: The braided hose is then cut to the required length. End fittings, such as threaded connections or flanges, are attached to the hose. This is typically done through a welding or crimping process to ensure a secure, leak-proof connection that can handle the specified pressure.

Quality Control and Testing: The final product undergoes rigorous testing to ensure its integrity and safety. This includes pressure and burst testing, leak detection, and visual inspections to check for any defects in the braid or fittings. Only after passing these checks is the hose ready for packaging and shipment.

The lifespan of stainless steel braided hoses can vary widely, but a properly installed and well-maintained hose can last anywhere from 5 to 20 years or even longer. The specific application and environmental conditions are the most significant factors affecting a hose’s longevity.

Here are some key factors that influence how long a stainless steel braided hose will last:

Inner Core Material: The material of the inner tube (e.g., rubber, PTFE) is often the first component to degrade. Hoses with a Teflon (PTFE) core generally have a longer lifespan, especially in high-temperature or chemical applications, as they are less susceptible to aging and deterioration than rubber.

Operating Conditions: The hose’s lifespan is significantly affected by the pressure, temperature, and type of media it is handling. Hoses used in high-pressure or high-temperature applications, or those exposed to corrosive chemicals, will generally have a shorter life than those in less demanding environments.

Installation and Usage: Proper installation is crucial. A hose that is kinked, twisted, or stretched beyond its recommended bend radius will experience premature fatigue and failure. In dynamic applications with repetitive flexing, the hose’s cycle life is a critical consideration.

External Environment: Exposure to harsh external conditions, such as extreme temperatures, sunlight (UV), or abrasive materials, can damage the outer stainless steel braid, reducing its protective function and shortening the hose’s overall life.

Quality and Grade: The quality of the materials used in manufacturing, including the grade of stainless steel (e.g., 304 vs. 316), and the overall construction of the hose play a major role in its durability and resistance to corrosion and wear.

While stainless steel braided hoses are known for their durability, it is always a good practice to perform regular inspections for signs of wear, such as fraying of the braid, kinks, or leaks, and to replace them proactively, especially in critical applications.

Stainless steel braided hoses are flexible, durable hoses reinforced with stainless steel wire, designed to handle high pressure, temperature, and corrosive environments.

They are widely used in industrial, automotive, and commercial applications where reliable fluid or gas transfer is critical.

Hydraulic Systems: Stainless steel braided hoses are used in hydraulic machinery to transfer hydraulic fluids under high pressure. Their reinforced structure ensures leak-free performance, reduces vibration, and withstands extreme temperatures, improving system efficiency and reliability in demanding industrial applications.

Automotive Applications: These hoses are used for brake lines, fuel transfer, and turbocharger systems in vehicles. The stainless steel braid provides durability, flexibility, and resistance to abrasion and corrosion, ensuring safe, long-lasting performance under high pressure and varying temperatures.

Chemical and Pharmaceutical Industry: Stainless steel braided hoses safely transport corrosive chemicals, steam, and other industrial fluids. Their corrosion-resistant construction protects against leaks and contamination, ensuring compliance with safety standards and consistent operation in sensitive chemical or pharmaceutical processes.

Food and Beverage Industry: Used for transferring hot liquids, gases, or steam in food and beverage production, these hoses maintain hygiene, resist corrosion, and provide durability under continuous operation. Their flexible design allows easy installation in complex production setups.

General Industrial Applications: Stainless steel braided hoses are versatile for transferring water, air, oil, steam, or other fluids in factories, plants, and workshops. Their high-pressure tolerance, corrosion resistance, and flexibility make them ideal for both stationary and mobile industrial equipment.

Cutting stainless steel braided hose requires the right tools and technique to get a clean, straight cut without fraying the metal braid. Fraying not only makes it difficult to install fittings but can also cause debris to contaminate the line.

Here are the most effective methods for cutting braided stainless steel hose:

This is one of the most common and recommended methods for a clean, non-frayed cut.

Tools: A chop saw, angle grinder, or a rotary tool (like a Dremel) with a thin abrasive cutting wheel is ideal.

Procedure: Before cutting, wrap the hose tightly with electrical or masking tape at the desired cut point. The tape holds the braid together and prevents it from fraying. Use the cutting wheel to make a slow, steady cut through the center of the taped area.

Tip: Go slowly with light pressure to avoid generating too much heat, which can damage the inner core. Always wear safety glasses and be sure to clean the inside of the hose thoroughly after cutting to remove any metal particles or debris.

For those who frequently work with braided hoses, specialized cutting shears are a great investment.

Tools: These shears have strong, hooked jaws and are specifically designed to cut through the tough stainless steel braid. They often resemble heavy-duty cable cutters or bolt cutters.

Procedure: Simply place the hose between the jaws and apply firm, even pressure to make a single, clean cut.

Tip: This method produces a very clean cut with minimal fraying and doesn’t create any metal debris, eliminating the need for post-cut cleanup. However, some users have noted that certain shears can slightly crimp the hose, especially on smaller diameters.

A metal-cutting bandsaw can also be used, though it requires a careful approach.

Tools: A bandsaw with a fine-toothed blade designed for cutting metal.

Procedure: Clamp the hose securely in a vice. Slowly feed the hose into the blade, making sure not to apply too much pressure, which could cause the braid to tear or fray.

Tip: Like the other methods, wrapping the hose with tape beforehand is recommended to help maintain the braid’s integrity.

Hacksaw: While it may seem like a viable option, a hacksaw is the worst tool for this job. It will almost always fray the stainless steel braid, making it nearly impossible to attach fittings cleanly.

Tin snips or standard pliers: These tools will flatten and crush the hose, destroying its shape and making it unusable for fittings.

Installing AN fittings on a steel braided hose is a precision-based process that requires careful attention to detail. This method ensures a secure, leak-proof connection suitable for high-pressure fluid transfer systems in automotive and other demanding applications.

Before starting, ensure the hose is cut cleanly and squarely, without any fraying. The AN fitting consists of two main parts: the socket and the nipple. Slide the socket over the end of the hose, ensuring it faces the correct direction for threading later.

The socket should be pushed down far enough so that about 1/8″ to 3/16″ of the hose is visible past the socket. This ensures the nipple has enough surface area to grip onto. Use a vice with soft jaws to hold the hose firmly, preventing it from twisting during assembly.

Lubricate the threads of the nipple and the inside of the socket with a suitable lubricant, such as engine oil or assembly lube. Carefully insert the nipple into the end of the hose, ensuring it is centered. Begin to thread the nipple into the socket by hand.

Once hand-tight, use AN wrenches to tighten the fitting. Continue to tighten until the nipple bottoms out against the socket. Avoid over-tightening, which can damage the fitting or the hose’s inner core. The hose’s end should be flush with the nipple’s conical sealing surface.

After assembly, inspect the fitting for any signs of damage or incorrect seating. The hose should be straight and not twisted inside the fitting. If possible, pressure test the assembled hose to ensure there are no leaks. This is especially critical for fuel, oil, or brake lines.

A properly assembled AN fitting creates a reliable, high-pressure seal without the need for thread sealants. A thorough inspection and testing process will confirm the integrity of the connection, providing confidence in the hose assembly’s performance under operational conditions.

Stainless steel braided hoses are primarily used for applications that demand high durability, pressure resistance, and temperature tolerance. Their robust construction, featuring a flexible inner core and a reinforcing stainless steel outer braid, makes them ideal for safely transferring fluids and gases in harsh or critical environments where standard hoses would fail.

They prevent kinking, resist abrasion, and maintain integrity under extreme stress.

Automotive: Used for high-performance brake lines, fuel lines, oil coolers, and turbocharger systems, where they must withstand high pressures and temperatures.

Industrial Machinery: Essential for hydraulic and pneumatic systems on heavy equipment and factory automation, providing reliable fluid power and resisting damage from physical stress.

Plumbing: Commonly used for flexible water and gas connectors in both residential and commercial settings, offering durability and ease of installation.

Aerospace: Employed in aircraft hydraulic systems, fuel delivery, and engine lubrication, where safety and performance under extreme conditions are non-negotiable.

Marine: Crucial for fuel, water, and hydraulic lines on boats and ships, as they offer excellent resistance to corrosion from saltwater.

Nylon and stainless steel braided hoses are both used for demanding applications, but they differ significantly in their construction, performance characteristics, and ideal use cases. While nylon offers advantages in weight and flexibility, stainless steel provides superior strength and resistance to extreme conditions. The choice between them depends entirely on the specific requirements of the application, including pressure, temperature, and environmental factors.

Construction: Nylon braided hoses feature a flexible inner tube typically made of rubber or a synthetic polymer, wrapped in a woven nylon fiber braid. Stainless steel braided hoses use a similar inner tube but with a much stronger outer layer of tightly woven stainless steel wire.

Performance: Stainless steel hoses are engineered for high pressure, extreme temperature, and abrasion resistance. Nylon hoses are better suited for moderate pressure and temperature applications where flexibility and lightweight materials are a priority.

Weight & Flexibility: Nylon hoses are significantly lighter and more flexible, making them easier to install and route in tight spaces. Stainless steel hoses, while durable, are heavier and have a more limited bend radius due to the rigid metal braid.

Durability & Longevity: The stainless steel braid offers superior protection against kinking, cuts, and external damage, resulting in a longer lifespan in harsh environments. Nylon hoses, while resistant to many chemicals and abrasion, can be more susceptible to degradation from heat and physical stress over time.