At Kingdaflex, we provide comprehensive support to help you select, install, and use hydraulic hoses safely and efficiently. Our support system is designed to assist you at every stage—from pre-sales consultation to after-sales service.

Our technical support team has extensive experience in hydraulic hose applications across construction, agriculture, mining, industrial equipment, and fluid power systems. Whether you need help choosing the correct hose specification, understanding pressure ratings, or resolving performance issues, our specialists are ready to support you.

We offer clear guidance on product selection, logistics and delivery, installation recommendations, maintenance practices, and troubleshooting. All support information is structured to help you quickly find accurate answers and reduce downtime in your hydraulic systems.

For order-related inquiries, shipping updates, or documentation such as datasheets and catalogs, our customer service team ensures timely and reliable assistance. If your application requires a customized solution, we work closely with you to meet specific technical and operational requirements.

Our goal is simple:

to ensure your hydraulic hose systems operate safely, reliably, and efficiently throughout their service life.

We offer flexible global logistics support for hydraulic hose orders. Products are packed to international export standards, with standard or customized packaging available.

Stock and custom lead times are clearly defined, supporting sea, air, and courier shipping under EXW, FOB, CIF, CFR, or DDP terms, with full shipping documents provided.

Our technical team supports proper hydraulic hose selection and application. We provide guidance on pressure, temperature, fluid compatibility, hose standards, and fitting matching.

If requirements are unclear, our engineers review operating conditions and recommend suitable hose solutions to ensure safety, performance, and compliance with SAE, EN, ISO, and DIN standards.

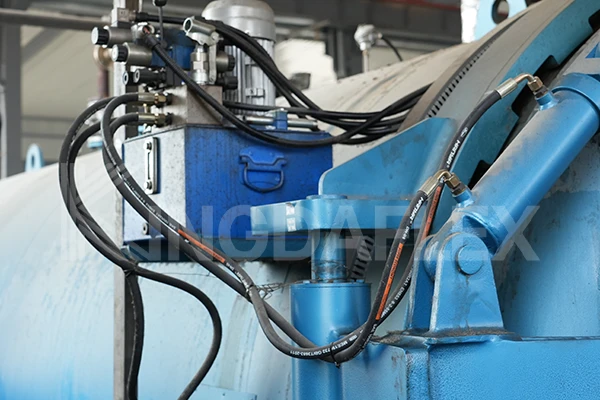

We provide practical guidance to ensure correct hose installation and long service life. This includes routing, clamping, bend radius control, abrasion protection, storage recommendations, and inspection intervals.

Proper installation and maintenance help reduce downtime, prevent premature failure, and improve overall hydraulic system reliability and safety.

Our team assists with diagnosing hydraulic hose performance issues and identifying root causes. We help address leakage, burst failures, abrasion, cracking, pressure loss, and overheating.

By analyzing hose selection, installation methods, and operating conditions, we support corrective actions that extend hose service life and prevent repeat failures.

All hydraulic hoses are produced under strict quality control and tested to applicable standards. We provide warranty coverage for manufacturing defects under proper use.

In case of quality issues, customers can submit order details and failure information for evaluation. Our team responds promptly to ensure efficient resolution and long-term cooperation.

We supply complete technical documentation to support engineering and procurement needs. This includes product catalogs, datasheets, standards references, hose selection guides, and installation recommendations.

Documents are available upon request through our support team to ensure accurate product selection, proper application, and smooth project execution.

Bruce Liu

Andrew Cao

Sonya Sun

Select a hose based on working pressure, temperature range, fluid type, application environment, and applicable standards. If unsure, contact our technical support team.

Service life depends on operating conditions, installation quality, and maintenance. Regular inspection is recommended, and hoses should be replaced according to industry guidelines or visible wear.

Not all hoses are compatible with all fluids. Always confirm fluid compatibility before use to prevent hose degradation.

Store hoses in a clean, dry environment away from direct sunlight, heat sources, ozone, and chemicals. Avoid sharp bending during storage.

Yes. We provide customized hose solutions based on specific pressure, size, length, branding, or application requirements.

As a professional hydraulic hose manufacturer, we provide technical consultation and responsive support for your applications. Our experienced team reviews your requirements, identifies suitable hose solutions, and offers clear recommendations and quotations to help you solve hydraulic challenges efficiently.