Sandblasting is an abrasive process that demands specialized equipment, and the sandblast hose is a critical component you can’t overlook. Using the wrong hose can lead to inefficiency, damage, and serious safety hazards. This guide will walk you through the essential factors to consider when selecting the perfect sandblast hose for your project.

Selecting the right sandblast hose is not just about finding a tube that fits; it’s about matching the hose’s specifications to your application’s unique needs. From pressure ratings and material composition to diameter and length, every detail plays a significant role in ensuring a safe and effective sandblasting operation.

What are Sandblast Hoses?

A sandblast hose is a specialized industrial hose designed to safely and efficiently transport abrasive materials, such as sand, shot, or garnet, at high velocity and pressure.

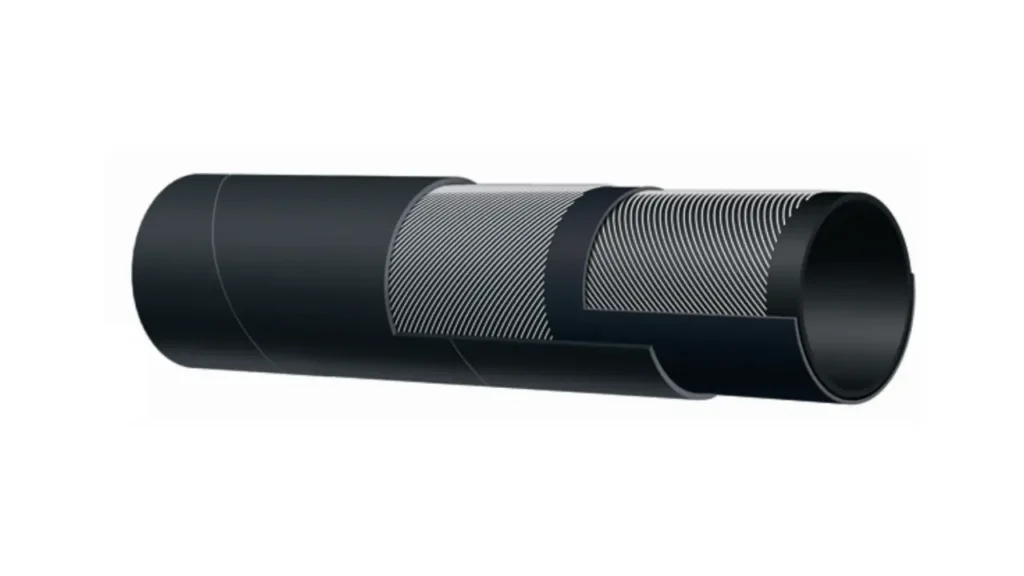

Unlike standard hoses, they are constructed with an exceptionally thick, highly abrasion-resistant inner tube to withstand the constant wear and tear from the fast-moving abrasive particles. The hose also features multiple layers of reinforcement, typically high-strength textile cords, to handle the high pressures required for effective blasting.

A durable outer cover protects the hose from external damage, including scuffs, cuts, and environmental factors. This robust construction is essential for ensuring safety, preventing premature wear, and maintaining consistent media flow for various surface preparation tasks, including cleaning, stripping paint, or shaping surfaces.

What are Sandblast Hoses Made of?

Sandblast hoses are meticulously engineered with a layered construction to withstand the high-velocity flow of abrasive media.

The primary materials used are in the sandblasting hose structure:

- Inner Tube: The innermost layer is made of a thick, highly abrasion-resistant and static-conductive rubber compound, typically a blend of natural rubber (NR) and Styrene Butadiene Rubber (SBR). This static-dissipating property is crucial to prevent the buildup of static electricity, which can create a shock hazard or cause sparks.

- Reinforcement: Encircling the inner tube are multiple plies of high-strength synthetic fabric cords, such as polyester. These layers, often referred to as “plies,” provide the hose with the necessary structural integrity to handle the high internal pressure from compressed air. The number of plies (e.g., 2-ply or 4-ply) determines the hose’s pressure rating and durability.

- Outer Cover: The exterior is a tough, durable rubber compound—often SBR or a blend—that is formulated to resist external abrasion, weather, and ozone. This protective layer ensures the hose can endure the rigors of harsh job site environments, preventing damage from being dragged, scuffed, or exposed to the elements.

What Size Hose for Sandblasting?

Choosing the right hose size for sandblasting is essential for effective performance and consistent results. The hose diameter and length affect airflow, pressure, and abrasive delivery. Selecting the correct size ensures efficient operation, reduces wear on equipment, and provides smooth, even blasting across different surfaces.

- 3/8-inch Hose – Light-Duty Use: We recommend a 3/8-inch hose for small, portable sandblasting tools. It delivers adequate airflow for light cleaning tasks and intricate work. Its flexibility allows easy maneuvering, prevents clogging, and ensures steady abrasive flow without overloading compressors or creating excessive pressure drop.

- 1/2-inch Hose – Medium-Duty Use: A 1/2-inch hose works best for standard sandblasting applications. We provide this size for general surface preparation and moderate abrasive consumption. It balances air pressure and flow, supports typical nozzle sizes, and ensures consistent abrasive delivery across medium-sized areas efficiently.

- 3/4-inch Hose – Heavy-Duty Use: For industrial or high-volume sandblasting, a 3/4-inch hose is ideal. We offer this size to handle long hose runs, large nozzles, and heavy abrasive use. Its larger diameter reduces pressure loss, maximizes airflow, and maintains consistent blasting performance for demanding projects.

- Consider Hose Length: Hose length significantly impacts blasting efficiency. We advise keeping hoses as short as practical or increasing diameter for long runs. This maintains consistent pressure, prevents airflow loss, ensures smooth abrasive delivery, and reduces strain on compressors and sandblasting equipment.

What is the Purpose of Sandblasting Hose?

The primary purpose of a sandblasting hose is to serve as a high-pressure conduit for safely and efficiently transferring abrasive media from the blast pot to the nozzle. Its robust, specialized design is essential for handling the punishing conditions of abrasive blasting, where materials like sand, shot, or grit are propelled at high velocity. The hose’s specific functions include:

- Abrasive Transfer: It provides a sealed pathway for the high-velocity flow of abrasive media and compressed air, ensuring a consistent and powerful stream is delivered to the work surface.

- Pressure Containment: Constructed with reinforced layers, the hose withstands the high internal pressures required for effective blasting, preventing dangerous ruptures or blowouts.

- Safety and Static Dissipation: The conductive inner tube dissipates static electricity generated by the friction of the media, preventing shocks to the operator and eliminating the risk of sparks that could ignite flammable materials in the work environment.

- Flexibility and Maneuverability: While tough, the hose remains flexible enough to allow the operator to navigate and direct the nozzle with precision, reaching various angles and surfaces on the workpiece.

Sandblast Hose Uses

At Kingdaflex, our sandblast hoses are designed for safe, efficient, and durable abrasive material transfer across various industries. They are ideal for industrial, construction, automotive, and marine applications, providing flexibility, high-pressure resistance, and long-lasting performance for surface preparation, cleaning, and material removal tasks in demanding environments.

- Industrial Sandblasting: We use sandblast hoses to clean, polish, or prepare metal and concrete surfaces in factories and workshops. Their reinforced design ensures consistent abrasive flow, protects equipment, and allows safe, long-term operation in heavy-duty industrial applications.

- Construction and Maintenance: We provide hoses for construction tasks like rust removal, concrete cleaning, and debris clearing. They are built to handle abrasive materials efficiently while providing flexibility, durability, and ease of handling in rugged, on-site conditions.

- Automotive Restoration: Our hoses are ideal for vehicle restoration and refinishing, including paint stripping, corrosion removal, and surface preparation. They deliver controlled abrasive flow, protecting vehicle surfaces and ensuring efficient preparation for repair or repainting processes.

- Marine and Shipbuilding: We supply hoses suitable for cleaning ship hulls, removing barnacles, rust, and marine debris. Their abrasion-resistant construction ensures safe, long-lasting performance even in harsh saltwater and high-pressure marine environments.

- Surface Preparation and Coating Removal: We provide hoses for removing coatings, rust, or unwanted layers before painting or welding. They enable precise, consistent abrasive delivery, ensuring effective surface preparation while maintaining operator safety and equipment longevity.

4-PLY Sandblast Hose vs 6-PLY Sandblast Hose

When choosing a sandblast hose, the ply count is a key factor in determining its durability, pressure capacity, and application suitability. The “ply” refers to the number of reinforcement layers within the hose wall. A higher ply count indicates a more robust and rigid hose.

Durability and Abrasion Resistance

A 4-ply sandblast hose is a common choice for many industrial applications. Its construction provides a good balance of strength and flexibility, making it durable enough to withstand external scuffs and occasional light vehicle traffic without collapsing. It is well-suited for heavy-duty jobs in environments like shipyards and rail yards.

A 6-ply sandblast hose, on the other hand, offers a superior level of durability. The additional reinforcement layers make it exceptionally tough and resistant to external abuse. While less common, a 6-ply hose is built for the most extreme, punishing environments where the hose is subject to frequent dragging over rough surfaces, heavy foot traffic, or is at a higher risk of being run over by vehicles.

Pressure Rating

The pressure rating of a hose is directly related to its ply count. A 4-ply hose typically has a working pressure rating suitable for standard abrasive blasting operations. This level of pressure is sufficient for most industrial applications.

A 6-ply hose, with its increased reinforcement, is designed to handle higher working pressures. The extra layers provide a greater safety margin against pressure spikes and ensure the hose maintains its integrity under more demanding conditions.

Flexibility and Weight

Flexibility is a critical consideration for operator comfort and maneuverability. A 4-ply sandblast hose is more flexible and lighter than a 6-ply hose, which makes it easier for the operator to handle, especially for jobs that require frequent movement and reaching tight spaces.

Due to its thicker wall and extra reinforcement, a 6-ply hose is considerably more rigid and heavier. This reduced flexibility can lead to increased operator fatigue and makes the hose more challenging to maneuver, particularly for long runs or in confined areas.

Cost

The cost of a sandblast hose increases with its ply count. A 4-ply hose is a more cost-effective option and provides excellent value for its durability and performance in most applications. It is a standard choice that balances initial cost with long-term reliability.

A 6-ply hose has a higher initial cost due to the additional materials and manufacturing processes. It is considered a premium hose, and the investment is justified for jobs where a 4-ply hose would fail prematurely due to extreme environmental conditions.

Recommended Applications

4-ply sandblast hoses are recommended for a wide range of industrial applications, including general-purpose sandblasting, construction, and shipyard work. They are the go-to choice for jobs that require a durable hose that can withstand typical on-site wear and tear without being excessively heavy or expensive.

6-ply sandblast hoses are used for the most demanding, heavy-duty applications where maximum durability and pressure capacity are required. They are typically reserved for specialized jobs in harsh environments, such as large-scale civil engineering projects or heavy-duty industrial blasting where equipment abuse is a constant factor.

Here are some differences between 4-ply sandblast and 6-ply sandblast hoses below:

| Aspect | 4-Ply Sandblast Hose | 6-Ply Sandblast Hose |

| Durability | Good; resists scuffs, cuts, and light vehicle traffic. | Excellent; built for extreme external abuse. |

| Pressure Rating | Standard pressure capacity for most industrial applications. | Higher pressure capacity and greater safety margin. |

| Flexibility | More flexible and lighter, reducing operator fatigue. | More rigid and heavier, leading to potential fatigue. |

| Cost | More cost-effective; a standard, reliable choice. | Higher initial cost; a premium option for extreme conditions. |

| Recommended Applications | General industrial use, shipyards, rail yards. | The most demanding, heavy-duty applications. |

How to Choose the Right Sandblast Hoses?

Choosing the right sandblast hose is crucial for maximizing efficiency, ensuring safety, and extending the lifespan of your equipment. Several key factors must be considered to make the best selection:

- Internal Diameter (ID): This is one of the most critical factors. The hose’s ID should be correctly matched to the nozzle size to maintain optimal pressure and media flow. A common rule of thumb is for the hose’s ID to be at least three to four times the nozzle’s orifice size.

- Pressure Rating: The hose’s rated pressure must be significantly higher than your system’s maximum operating pressure. A 3:1 safety factor is generally recommended to provide a buffer against sudden pressure spikes, which prevents dangerous ruptures.

- Hose Length: While a longer hose provides more reach, it can also cause a drop in air pressure due to increased friction, reducing blasting efficiency. Choose the shortest practical length for your application.

- Material and Construction: The inner tube must be made from a highly abrasion-resistant and static-conductive rubber to handle the abrasive media and prevent static shocks. The number of reinforcement layers (e.g., 2-ply or 4-ply) determines the hose’s durability and pressure capacity.

- Fittings and Couplings: Ensure the fittings are properly sized and securely attached to prevent leaks and premature wear. Nylon couplings are often recommended over metal for metal-threaded nozzles to reduce wear and tear.

Conclusion

Choosing the correct sandblast hose is a crucial decision that directly impacts the efficiency, safety, and longevity of your abrasive blasting operation. Remember to always prioritize factors like working pressure, abrasion resistance, and material quality. A hose that is ill-suited to the task can lead to costly downtime and pose significant risks to your crew.

By following the guidelines discussed in this blog, you’re now equipped to make an informed decision and select a hose that meets the specific demands of your project. Investing in a high-quality hose is an investment in both productivity and peace of mind, ensuring your equipment operates at its peak performance.

For all your industrial hose needs, consider Kingdaflex. We offer a wide range of wholesale sandblasting hoses designed for durability and performance, ensuring you get the right product at a competitive price. Visit our website to explore our full catalog and find the perfect solution for your abrasive blasting requirements.